Method and apparatus for dyeing cellulosic textile substrates with an inert leuco state dye and dyed product

a cellulosic textile and inert leuco state technology, applied in the direction of dyeing process, textiles, liquid/gas/vapor textile treatment, etc., can solve the problems of inability to dye cellulosic textiles, complex and expensive procedures,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

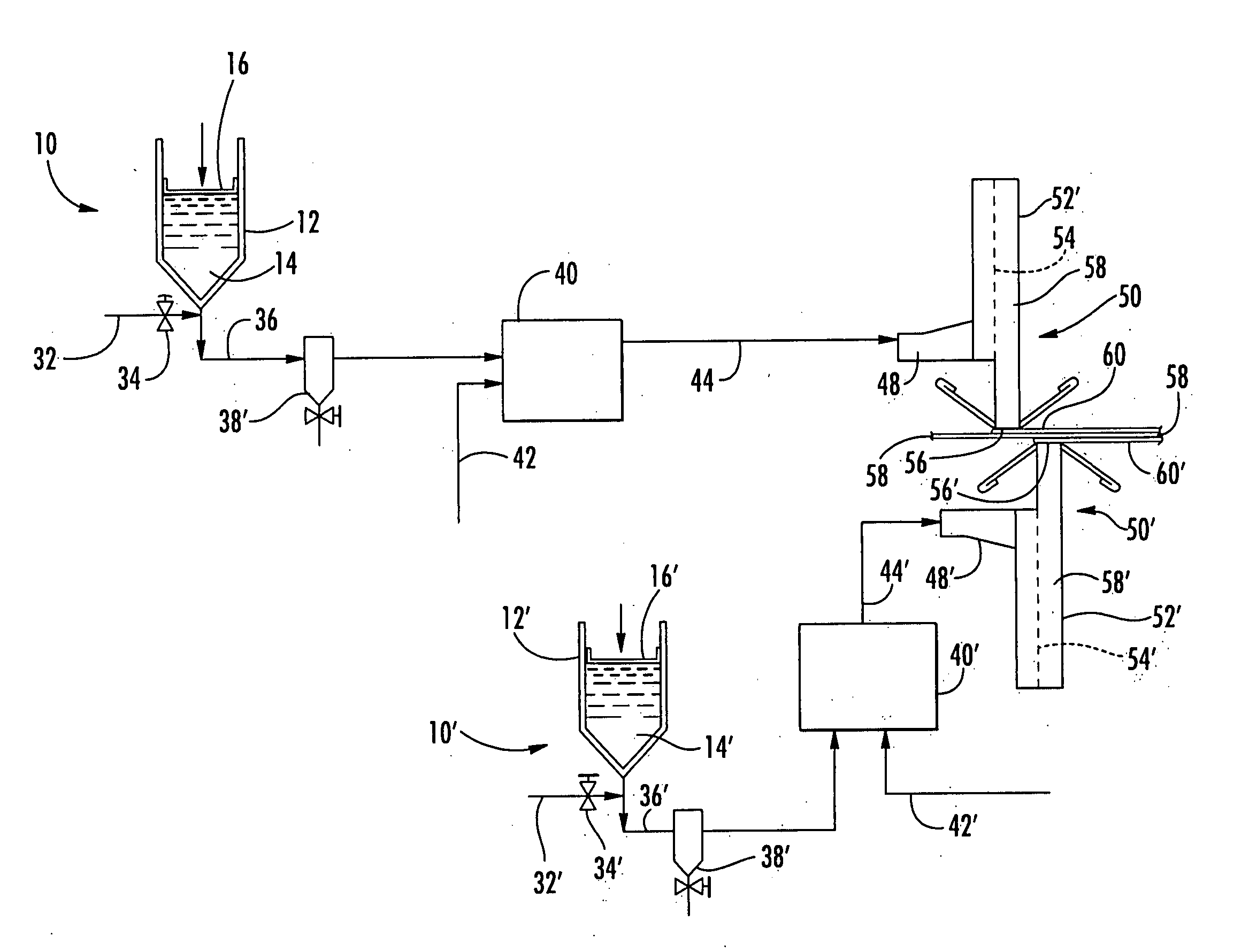

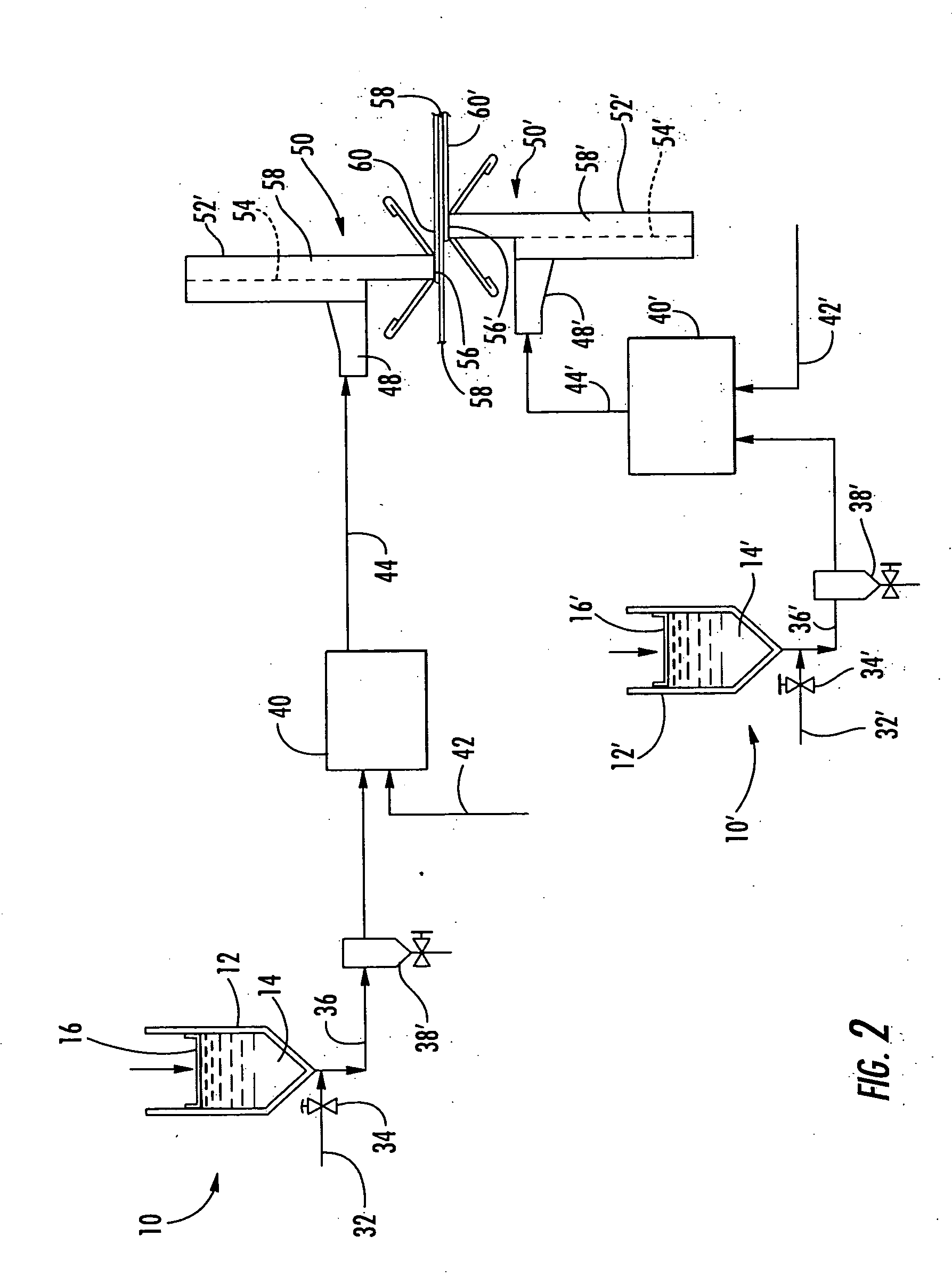

[0025] The apparatus 10 of the preferred embodiment of the present invention is illustrated in FIGS. 2, 3 and 4. Referring first to FIG. 2, the apparatus includes a supply container or feed tank 12 containing a supply of indigo dye 14 in a reduced leuco state. Conveniently, this indigo dye 14 can be used in the form received from a supplier, which typically may be a paste of 40% concentration. However, it is to be understood that various concentrations may be used as desired for particular dyeing application. For example, water can be added to reduce the concentration to any other suitable amount, such as 20%. Also, conventional pigments, penetrants and foaming agents can be added to vary the shade or color and to facilitate application. In a typical example, the pigment and penetrant additives may reduce the indigo dye concentration to, for example, 32%.

[0026] To maintain the dye in its leuco state in the feed tank 12, a floating cover 16 is positioned on top of the dye 14 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| deep color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com