Shell fabric bubble dyeing device

A dyeing device and fabric technology, applied in the treatment of textile materials, the treatment of liquid textile materials with a small liquor ratio, and the treatment of liquid/gas/steam textile materials, etc. problem, to achieve the effect of good random color distribution, good randomness, and unique artistic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

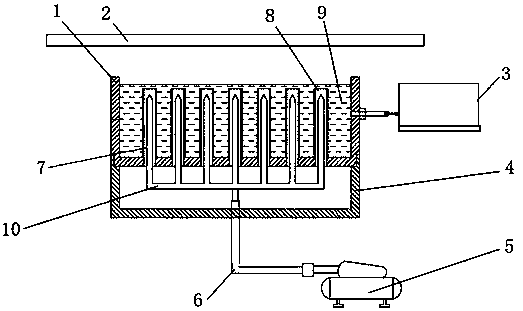

[0016] Such as figure 1 As shown, a fabric air bubble dyeing device includes a dye solution box 1, a fabric to be dyed and finished 2, a dye solution supply device 3, a pipeline cavity 4, a gas generator 5, an air flow main pipe 6 and several air flow branch pipes 7; The liquid supply device 3 is connected with the dye liquid tank 1 through the infusion tube; the upper end of the dye liquid tank 1 is provided with a dye liquid tank 9, and several foaming tubes 8 are arranged in the dye liquid tank 9, and the lower part of the dye liquid tank 1 is provided with a pipe cavity 4. The airflow main pipe 6 and the airflow branch pipe 7 are located in the pipeline cavity 4, and each airflow branch pipe 7 is located in a corresponding foaming pipe 8, and the open end of the airflow branch pipe 7 is lower than the upper end of the foaming pipe 8, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com