Apparatus and method of foam dyeing a traveling sheet of textile yarn

a textile yarn and foam dyeing technology, applied in the direction of dyeing process, textile treatment by spraying/projecting, application, etc., can solve the problem of difficult, if not impossible, to coat the entire surface of each yarn without leaving undyed streaks, and achieve the effect of deepening the color shad

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

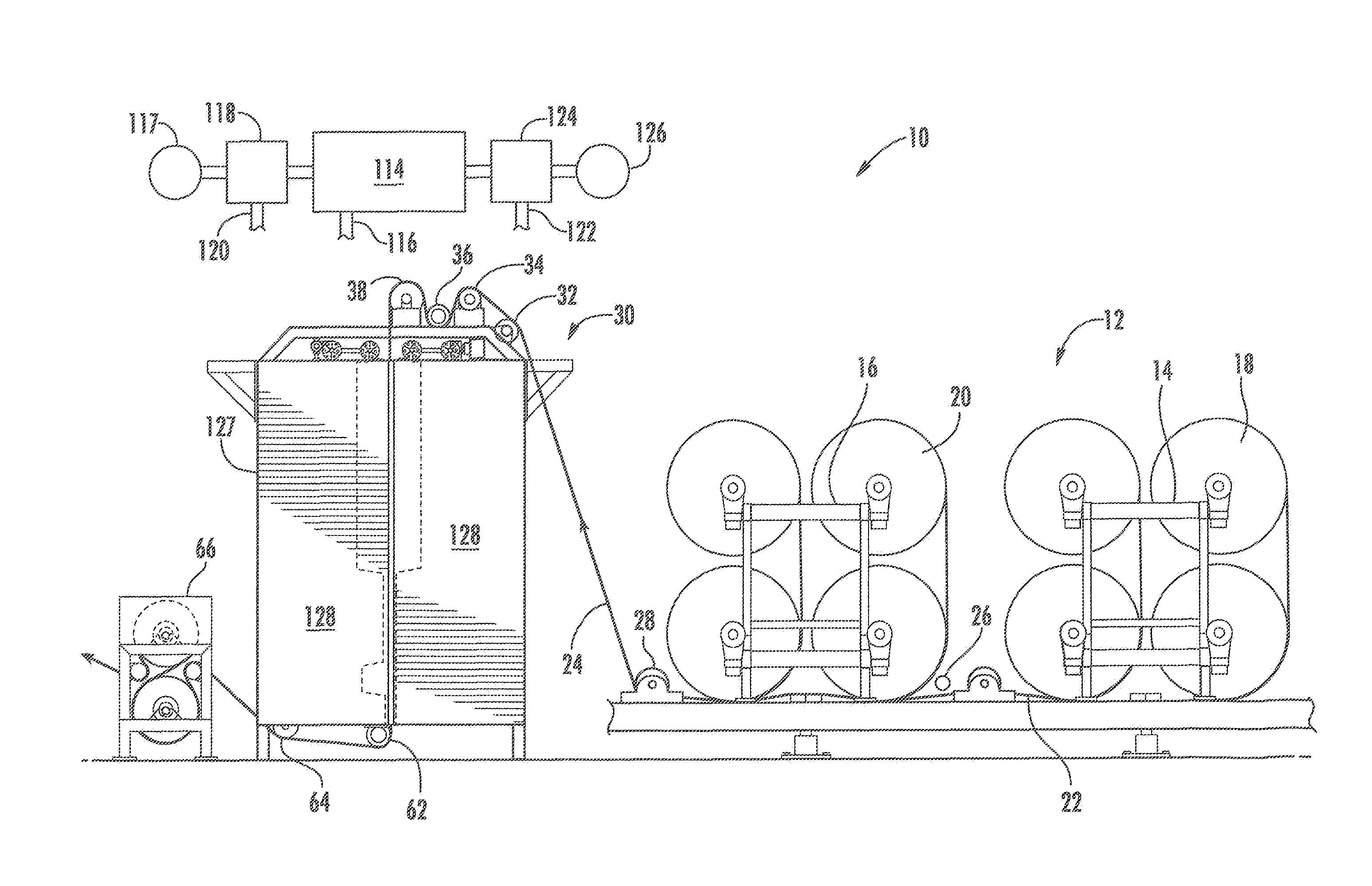

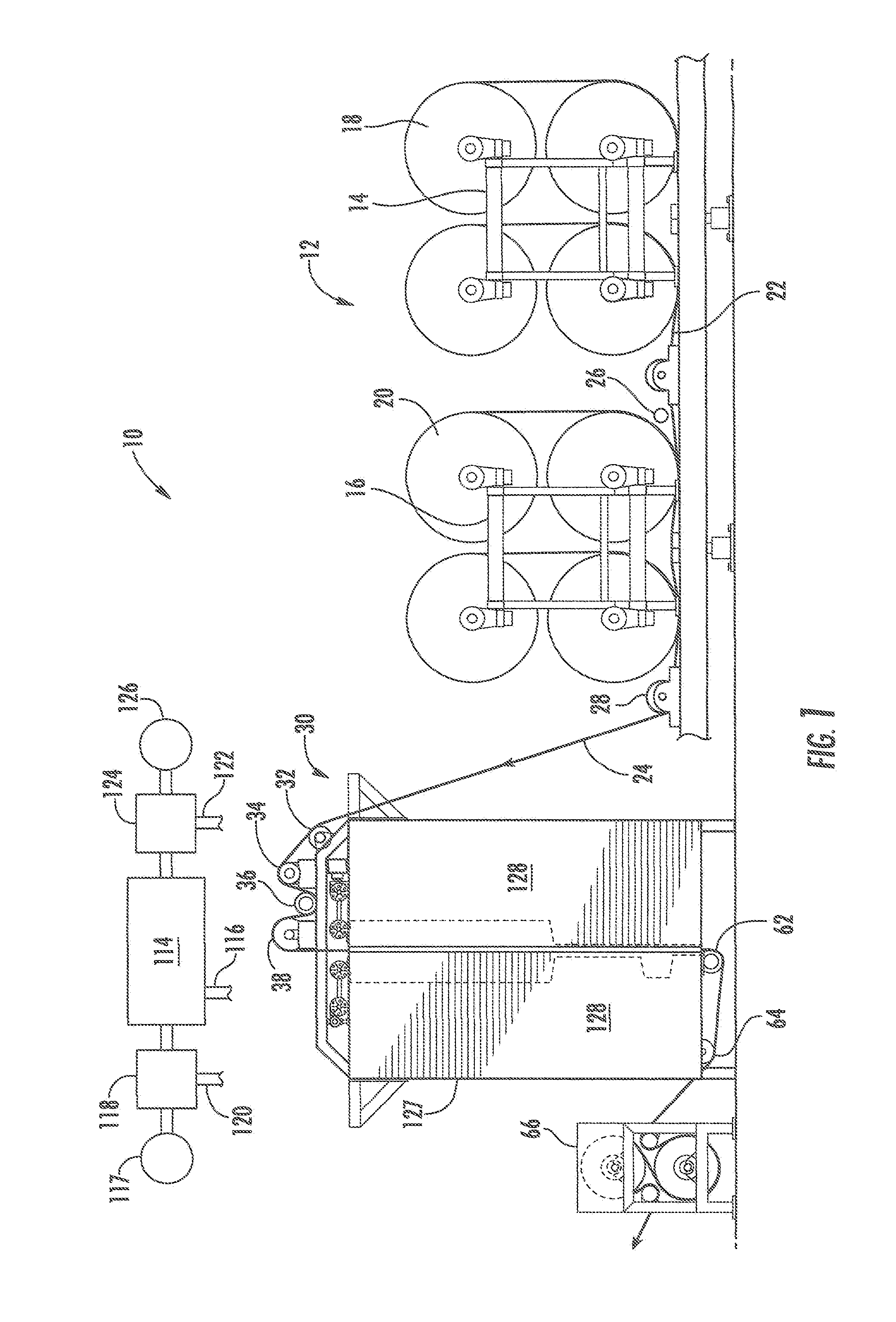

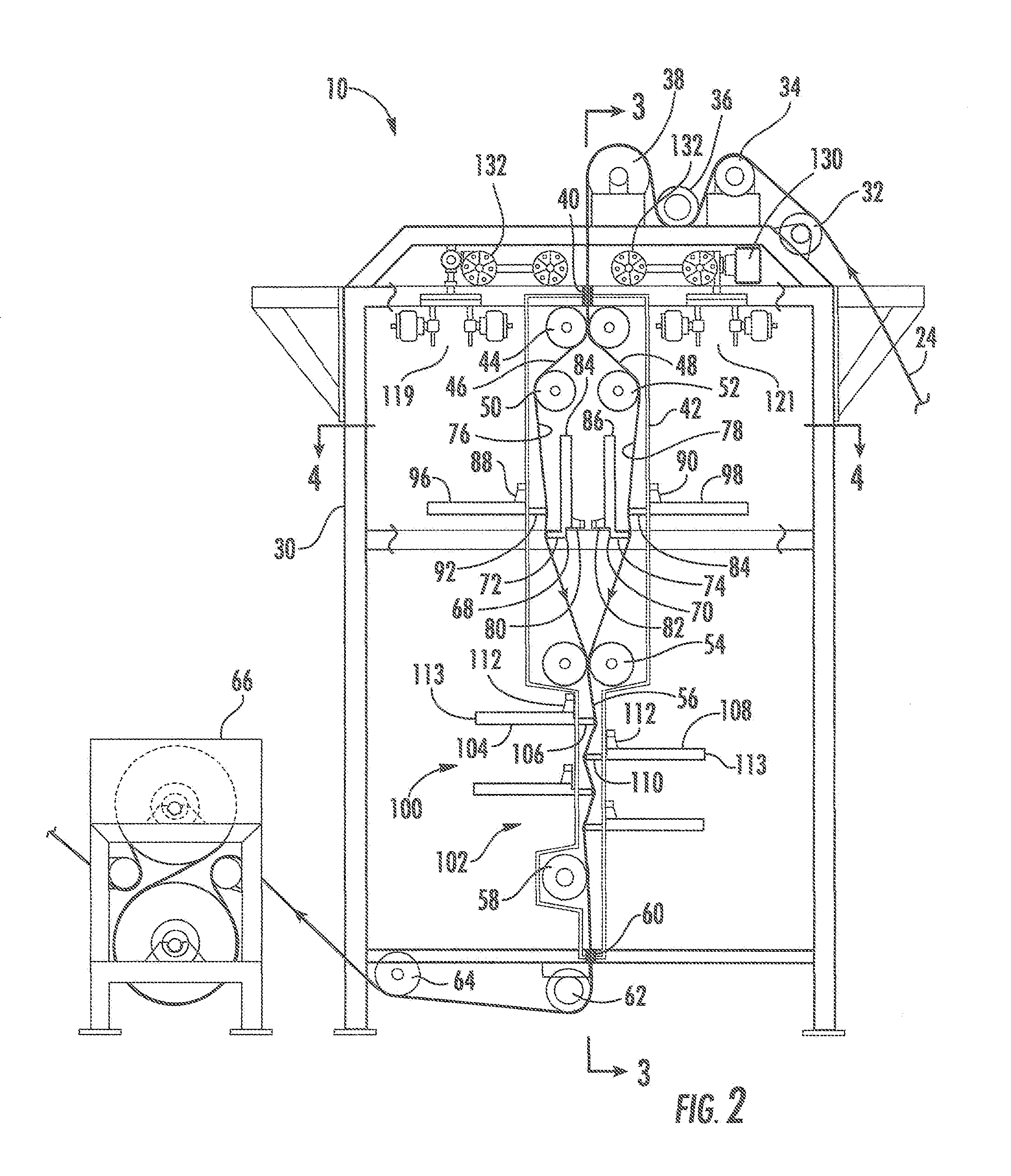

[0017]The dyeing apparatus 10 of the preferred embodiment of the present invention illustrated in the accompanying drawings, feeds originally undyed cotton yarns that are wound on warp beams 12 supported in two racks, 14 and 16, arranged in series with each rack supporting four warp beams 18 and 20 in a two over two stacking arrangement. One rack 14 is outboard of the other rack 16. Yarns from the four beams 18 of the outboard rack 14 are withdrawn and combined into a single yarn sheet 22 that passes under the beams 20 of the inboard rack 16 and combined with the yarns drawn from the beams 20 of the inner rack 16 to form a combined single sheet 24 drawn from the eight warp beams.

[0018]In threading up the apparatus 10, a cross yarn 26 is laid across the top of the sheet 22 of yarns from the outboard rack 14 prior to the sheet passing under the beams 20 of the inner rack 16. In this manner, the yarns from the inner rack 16 are laid on top of the cross yarn 26 in combining with the yar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Dyeing enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com