Multi-step process for dyeing textile materials with a concentrated dye system

A technology of textiles and dyes, which is applied in the direction of dyeing, textiles and papermaking, and textile material processing, which can solve the problems of low fastness, high cost, inconvenient measurement and control technology, etc., and achieve the increase and decrease of friction fastness The effect of textile waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Dyeing of Warp Yarn Sheets from Reduced Indigo Aerosol Media

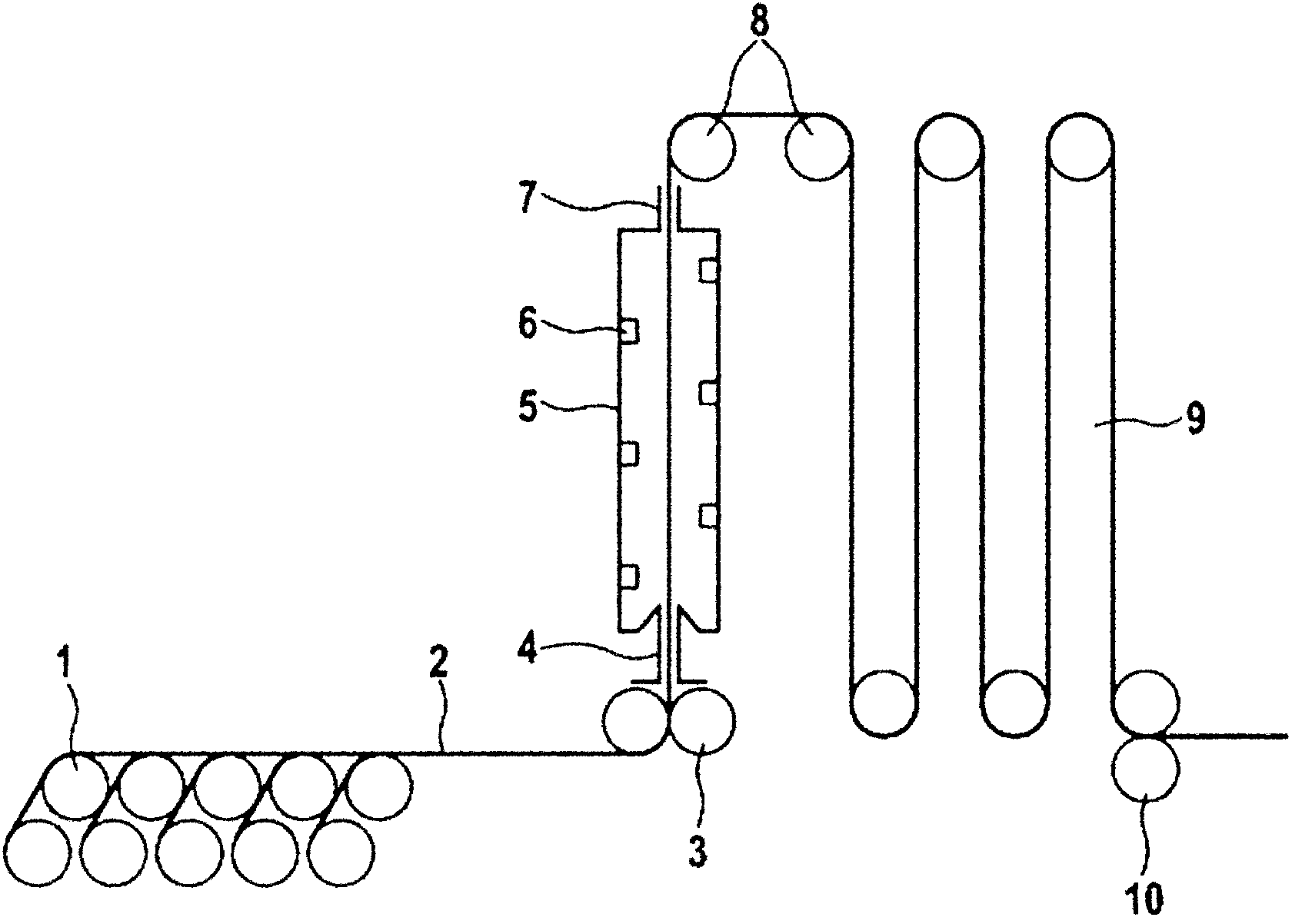

[0070] Dyeing is done on a machine according to figure 1 is done on the device and is controlled as follows:

[0071]Before starting the dyeing, the aerosol chamber 5 is filled with nitrogen to remove the air (i.e. oxygen) present there. This is done by means of multiple dual material nozzles on the spray arm 6 . Simultaneously, a pre-circulation of dyeing liquid from a collecting container via the liquid feed line to the spray arm 6 and back to the collecting container via the liquid return line is initiated. During this pre-running phase, the desired amount of dye liquor added is set via flow meters and associated control valves. To maintain a constant inlet pressure at the dye liquor feed line, pressure transducers and control valves are used to set and maintain the desired line pressure throughout the dyeing stage. Once the presetting phase has ended, the squeeze roll 4 is closed and the process is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com