Methods of treating textiles with foam and related processes

A technology for foaming, processing solutions, used in textile processing, fiber processing, textiles and paper making with small liquor ratios, which can solve problems such as limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Stone washed denim (denim)

[0046] Materials and methods : Table 3 contains the materials used throughout the experimental period.

[0047] Table 3. Materials used

[0048]

[0049] Processing of denim garments (5 garment samples, 700g each) with a laser device (mode 01hs, resolution: 150.000dpi on X-axis, 9.000dpi on Y-axis) to simulate visual effects such as scratches on denim ( strike) and lines (line). To stonewash using foam and cellulase, the garment is treated in a washing machine with an aqueous solution containing: ATB 710 (a liquid cellulase preparation capable of sanding at room temperature) 30 g / L; Fortres GSL (based on Dispersant for ionic surfactants, primarily added to limit back staining) 10 g / L; Anhydrous Citric Acid (to achieve pH 6.0) 0.4 g / L; and Foaming Agent #1 18 g / L. Foamer #1 was prepared according to the examples shown in Table 2.

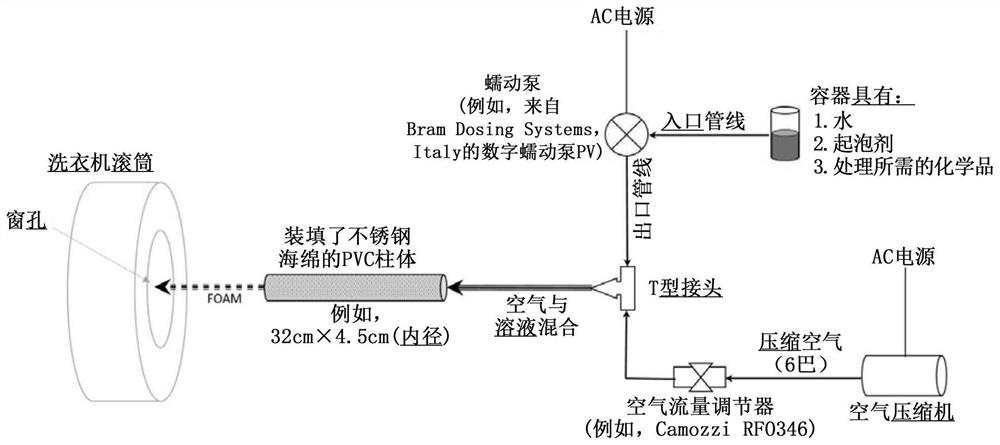

[0050] The composition is prepared and 700 grams of foam (per kilogram of garment) is inject...

Embodiment 2

[0054] Example 2: Bleaching of stonewashed denim using NaOCl and foam

[0055] Materials and methods : Table 5 contains the materials used throughout the experimental period.

[0056] Table 5. Materials used

[0057]

[0058] Processing of denim garments (5 garment samples, 700g each) with laser equipment (mode 01hs, resolution: 150.000dpi on X-axis, 9.000dpi on Y-axis) to simulate visual effects such as scratches on denim and line. Garments were then treated with foam and liquid cellulase as in Example 1. Then, dehydration was carried out by a centrifuge so as to retain 550 grams of water per kilogram of garment (55% dehydration rate). Garments were then bleached using a foam and NaOCl treatment; garments were treated using the same washing machine as above using an aqueous solution containing sodium hypochlorite (NaOCl); 200 g / L; and frother #2 (80 g / L). Foamer #2 was prepared according to the examples shown in Table 2.

[0059] The composition was prepared and 120...

Embodiment 3

[0063] Example 3: Using Avol Evanix and Foam Bleach

[0064] Materials and methods : Table 7 contains the materials used throughout the experimental period.

[0065] Table 7. Materials used

[0066]

[0067] Processing of denim garments (5 garment samples, 700g each) with laser equipment (mode 01hs, resolution: 150.000dpi on X-axis, 9.000dpi on Y-axis) to simulate visual effects such as scratches on denim and line. The garment is then bleached with foam and Avol Evanix by the garment treatment method in a washing machine using an aqueous solution comprising: Avol Evanix, which is a sodium persulfate activator produced by Kemin Textiles s.r.l., 520 g / L; synergist OW (active substance: Sodium Persulfate) 86 g / L; and Foaming Agent #1 (24 g / L).

[0068] The composition was prepared and 700 grams of the composition (per kilogram of garment) was injected into the washing machine within 5 minutes of starting garment treatment. Do a 15-minute suds bleach cycle in the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com