Method and apparatus for dyeing cellulosic textile substrates with a leuco-state dye

a cellulosic textile and inert technology, applied in the field of apparatus for dyeing cellulosic textile substrates with inert leucose dye, can solve the problems of inability to dye cellulosic textile materials with indigo dye, waste dye and water disposal, undesirable substantial expense and environmental problems, etc., to achieve the effect of reducing the entry ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

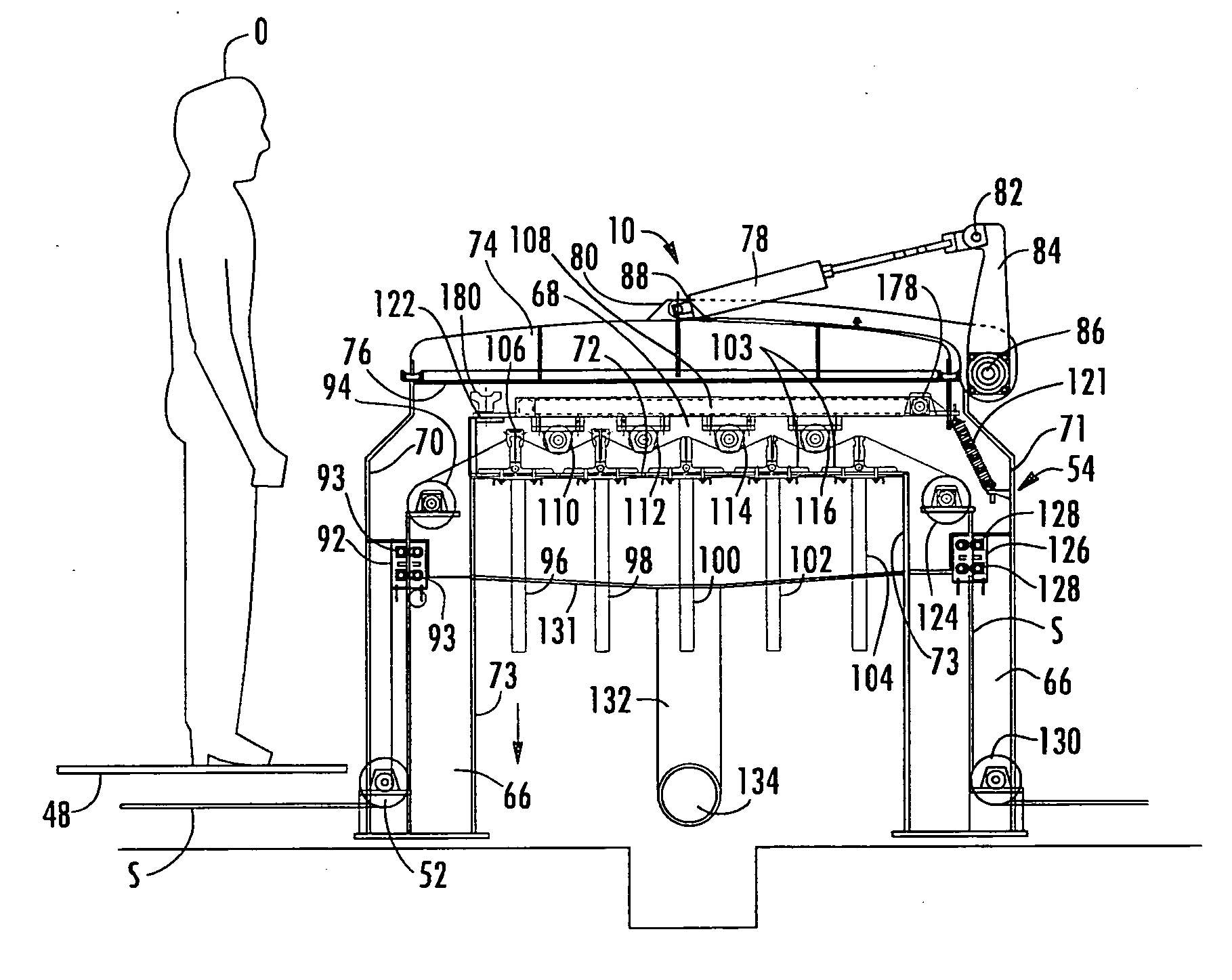

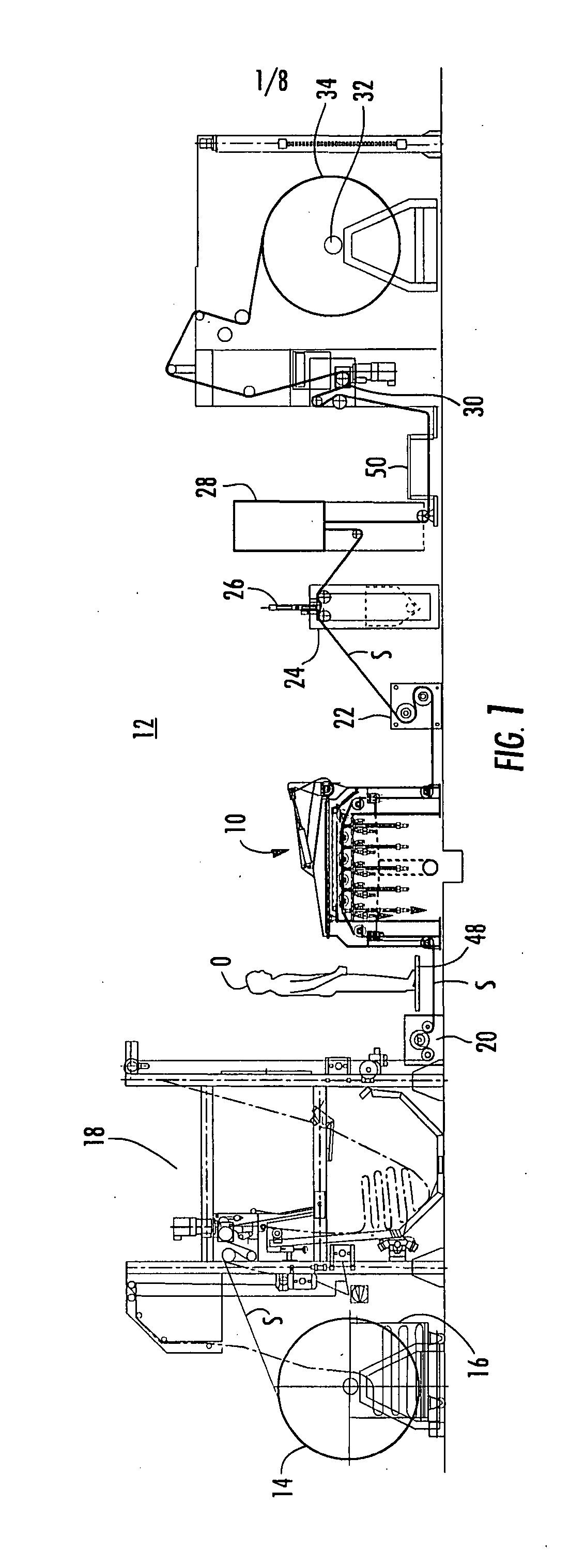

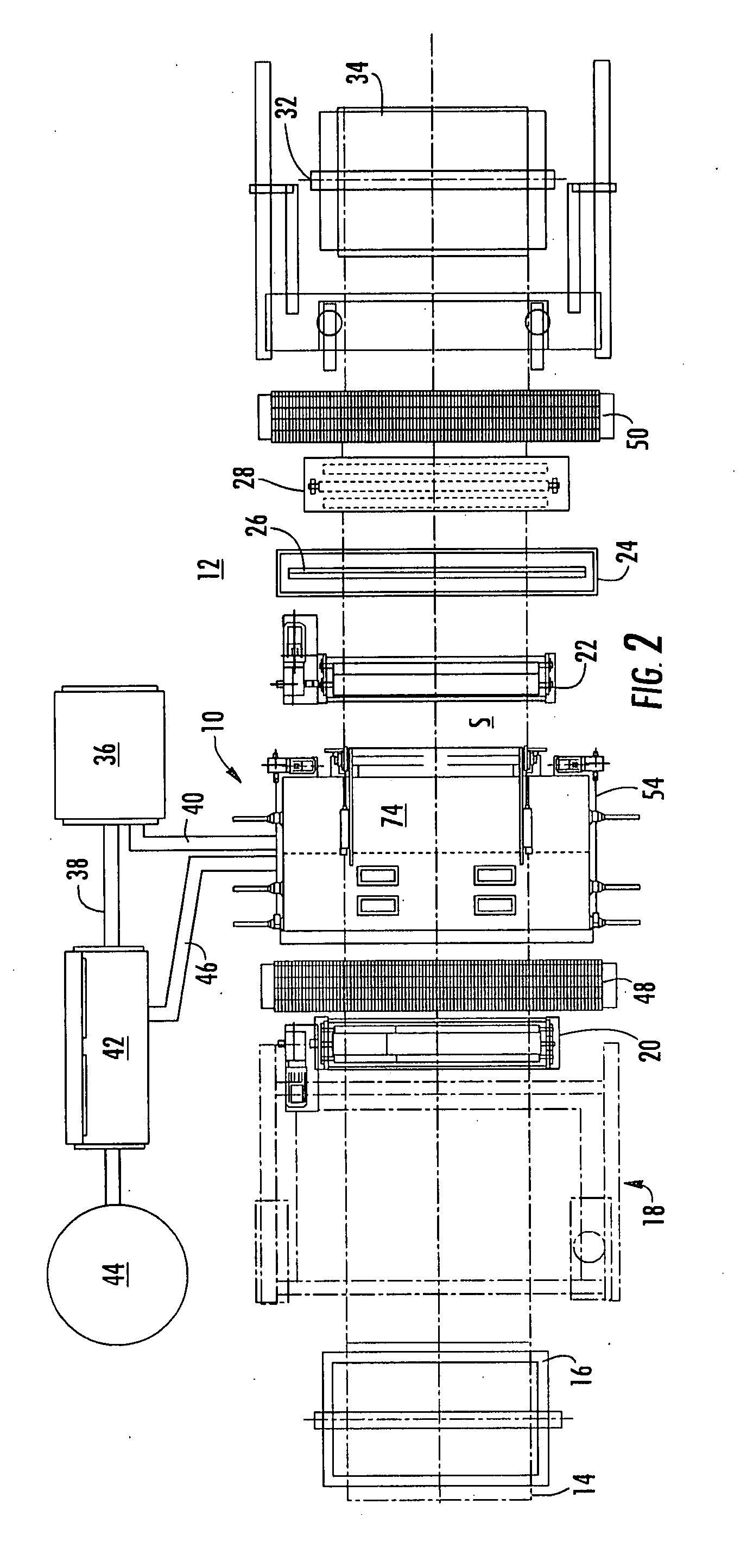

[0020] The dyeing apparatus 10 of the preferred embodiment of the present invention is illustrated in FIGS. 1 and 2 incorporated in a dyeing range 12. A sheet of textile substrate S is fed to the range 12 from a supply roll 14 or a supply of plaited material in a supply box 16. The substrate S is then relaxed in a J-box 18 from which it is withdrawn by a feed roll assembly 20 from which the substrate travels under a crosswalk grid 48 on which an observer O stands to monitor the dyeing operation in the dyeing apparatus 10. The substrate is drawn through the dyeing apparatus 10 by a driven pull roll assembly 22. The drive of the feed roll assembly 20 and pull roll assembly 22 are controlled so that a desired tension is being maintained in the substrate S as it travels through the apparatus 10. From the pull roll assembly 22 the substrate may be subjected to a supplemental treatment at a supplemental dye application station 24, at which a foam applicator 26 applies a surface treatment,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com