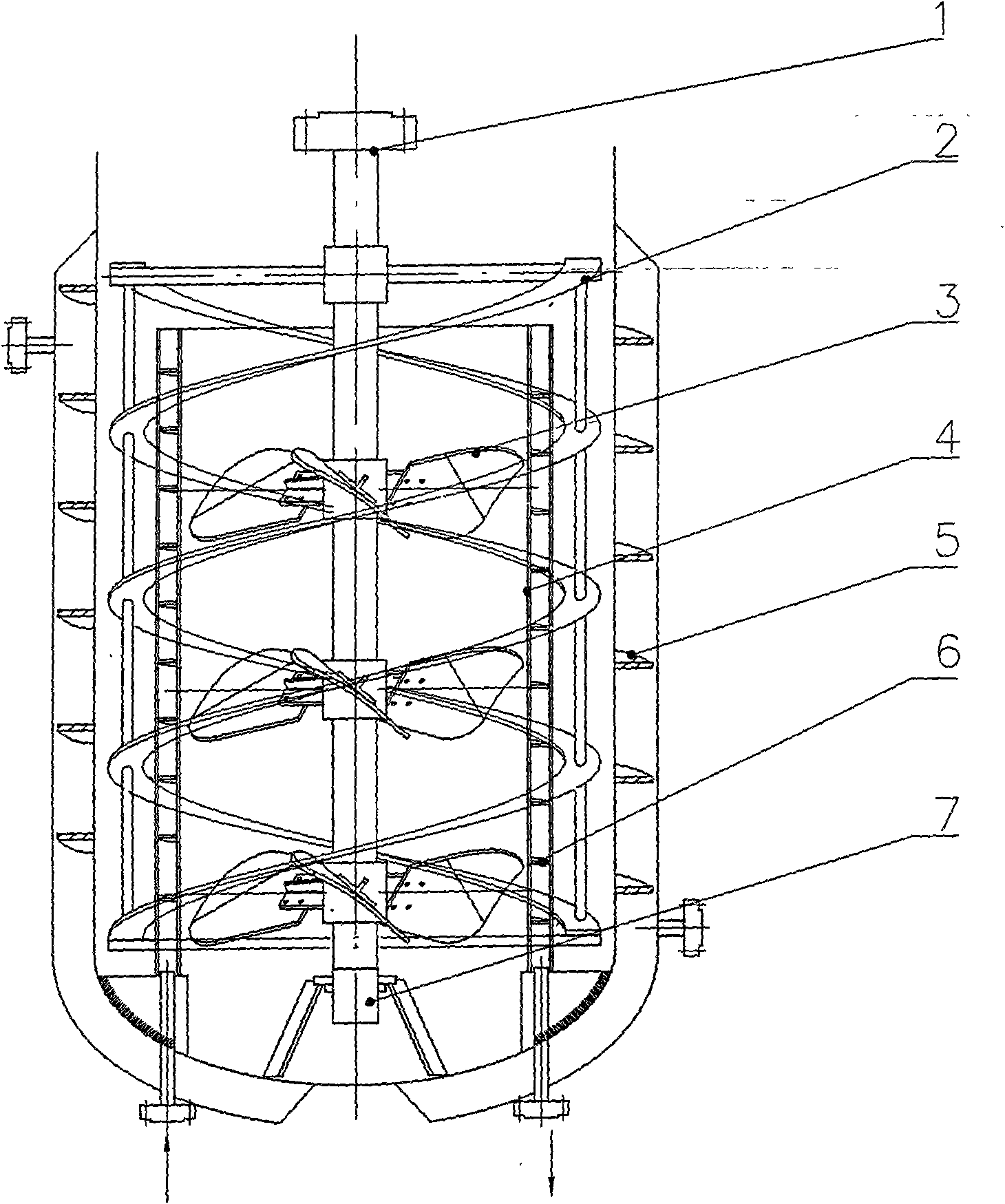

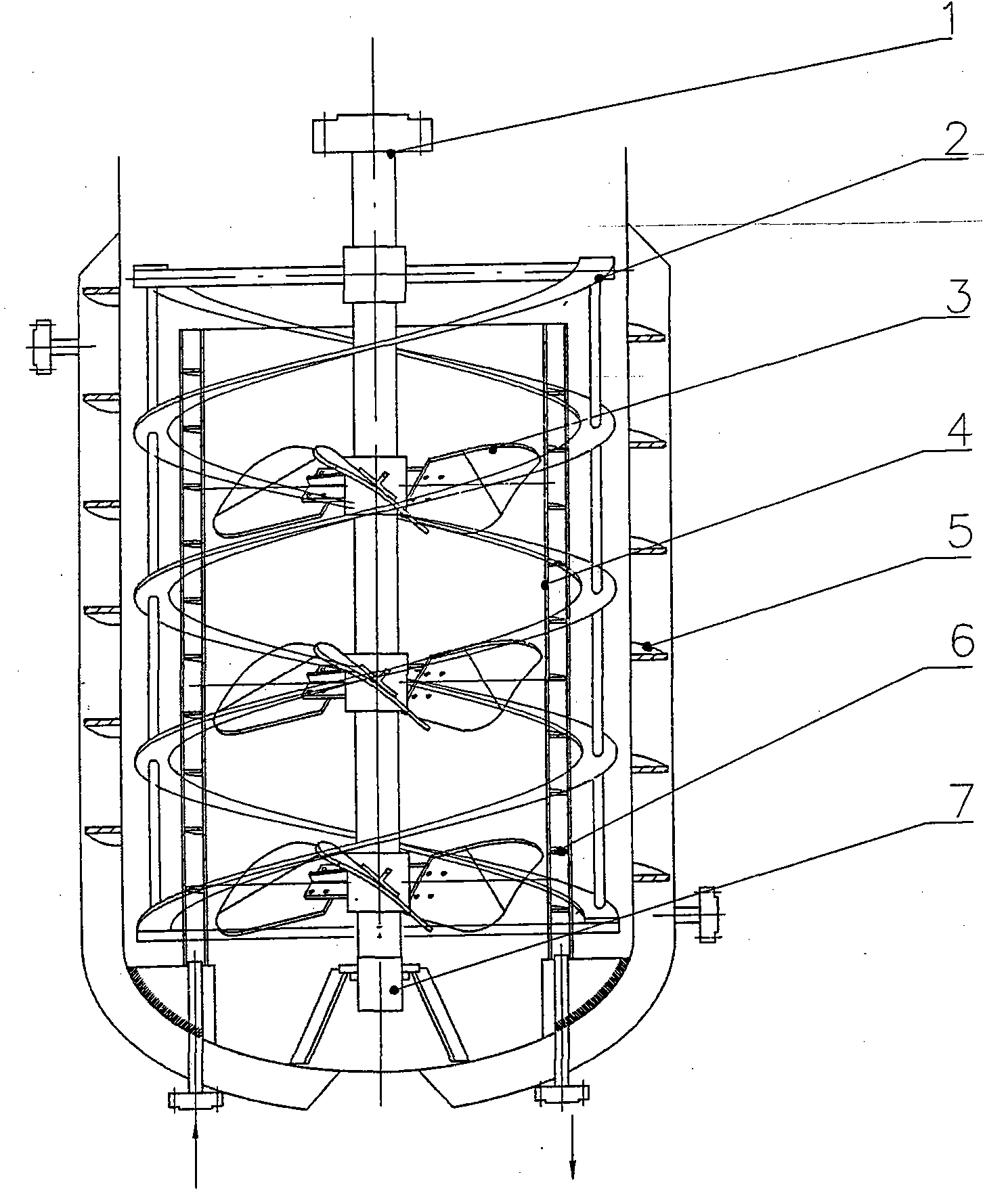

Compound stirring device for kettle

A technology of stirring device and heat transfer cylinder, which is applied to mixers with rotating stirring devices, accessories of mixers, mixers, etc., can solve the problems of lack of versatility and endless emergence of new technologies and materials, and achieves rapid circulation and timely promotion. The effect of accurately controlling the temperature of the polymerization system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] exist figure 1 In the shown embodiment of the compound stirring device for kettle, the shaft (1) rotates to drive the outer hollow ribbon (2) and the downward pressure propeller (3) to rotate, and the conduction and heat transfer cylinder (4) cooperates with the stirring to guide the flow, and at the same time The heat transfer effect of the inner jacket (6) of the kettle on the conduction heat transfer cylinder and the outer jacket (5) of the kettle cooperates to ensure the temperature uniformity of the medium in the kettle. Bottom bearing (7) support guarantees the firm stability of axle when working.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com