Device and method for producing methyl aniline through performing continuous liquid-phase catalytic hydrogenation reduction on nitrotoluene

A technology of nitrotoluene and methylaniline, which is applied in the field of continuous liquid-phase catalytic hydrogenation reduction of nitrotoluene to produce methylaniline, which can solve the problems of unstable product quality, large hydrogen consumption, and low utilization rate of equipment , to achieve good heat transfer effect, small equipment size and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

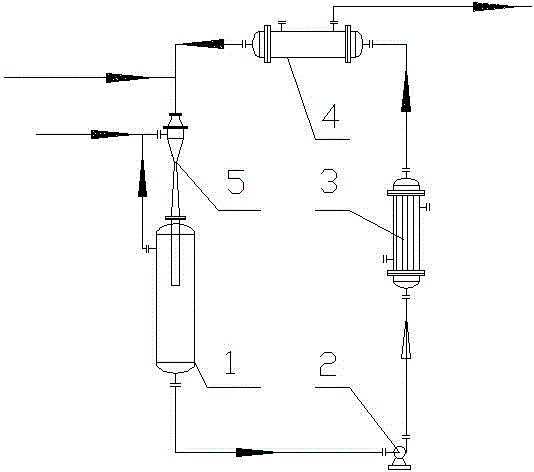

[0018] Example 1: Put nitrotoluene and a platinum-carbon (Pt / C) catalyst with a mass percentage of platinum of 1% into the hydrogenation reactor to lay out the bottom material, replace the air in the system with nitrogen, and then use hydrogen to purify the nitrogen The replacement is clean; the feed valve is opened, and nitrotoluene is continuously sent into the hydrogenation reactor. The mass ratio of nitrotoluene and noble metal catalyst is 1:0.001. 0.5MPa; the hydrogenation liquid mixed with the catalyst in the hydrogenation reactor first enters the heat exchanger through the circulating pump to remove the heat of reaction to maintain the reaction temperature of the system, and then passes through the cross-flow filter, the catalyst and part of the hydrogenation liquid are mixed with fresh nitrotoluene Enter the ejector to circulate, another part of the hydrogenated liquid is continuously extracted from the outlet of the hydrogenated liquid on the cross-flow filter, enters ...

Embodiment 2

[0019] Example 2: Put nitrotoluene and a platinum-carbon (Pt / C) catalyst with a mass percentage of platinum of 3% into the hydrogenation reactor to lay out the bottom material, replace the air in the system with nitrogen, and then use hydrogen to purify the nitrogen The replacement is clean; the feed valve is opened, and nitrotoluene is continuously sent into the hydrogenation reactor. The mass ratio of nitrotoluene and noble metal catalyst is 1:0.003. 1.0MPa; the hydrogenation liquid mixed with the catalyst in the hydrogenation reactor first enters the heat exchanger through the circulation pump to remove the reaction heat to maintain the reaction temperature of the system, and then passes through the cross-flow filter, the catalyst and part of the hydrogenation liquid are mixed with fresh nitrotoluene Enter the ejector to circulate, another part of the hydrogenated liquid is continuously extracted from the outlet of the hydrogenated liquid on the cross-flow filter, enters the...

Embodiment 3

[0020] Example 3: Put nitrotoluene and a platinum-carbon (Pt / C) catalyst with a mass percentage of platinum of 5% into the hydrogenation reactor to lay out the bottom material, replace the air in the system with nitrogen, and then use hydrogen to purify the nitrogen The replacement is clean; the feed valve is opened, and the nitrotoluene is continuously sent into the hydrogenation reactor. The mass ratio of nitrotoluene and noble metal catalyst is 1: 0.005, and hydrogen gas is introduced to carry out the hydrogenation reduction reaction. 1.5MPa; the hydrogenation liquid mixed with the catalyst in the hydrogenation reactor first enters the heat exchanger through the circulating pump to remove the reaction heat to maintain the reaction temperature of the system, and then passes through the cross-flow filter, the catalyst and part of the hydrogenation liquid are mixed with fresh nitrotoluene Enter the ejector to circulate, another part of the hydrogenated liquid is continuously ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com