Synthetic method of novel environment-friendly chlorine-resistant color fixing agent

A synthesis method and technology of color-fixing agent, applied in dyeing method, textile and papermaking, etc., can solve the problem of slow research progress, and achieve the effect of improving chlorine resistance, soaping fastness and various properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

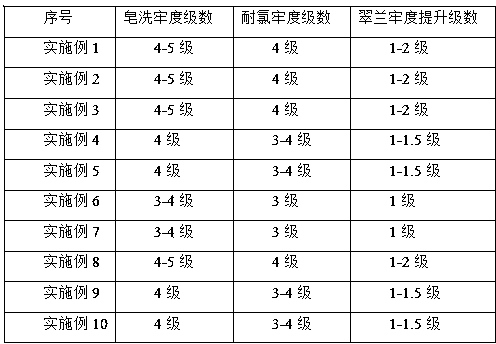

Examples

Embodiment 1

[0034] The synthetic method of novel environment-friendly chlorine-resistant color-fixing agent comprises the steps:

[0035] (1) Add 50g of epichlorohydrin, 80g of diethylenetriamine, and 80g of diallylamine into a round-bottomed flask equipped with a water separator and a condenser tube, mix and heat to 50°C, and the inside of the water separator The amount of water no longer increases;

[0036] (2) Weigh 3g of oxidizing agent and dissolve the oxidizing agent according to the mass ratio of oxidizing agent and water of 1:10 to obtain the oxidizing agent solution; weigh 3g of reducing agent and dissolve the reducing agent according to the mass ratio of reducing agent and water of 1:10, namely to obtain a reducing agent solution;

[0037] (3) Heat the temperature to 60°C, add 3.3g of oxidizing agent solution and 3.3g of reducing agent solution to the reaction system, after 0.5h, add 29.7g of oxidizing agent solution and 29.7g of reducing agent solution dropwise at 70°C for 3h ...

Embodiment 2

[0040] The synthetic method of novel environment-friendly chlorine-resistant color-fixing agent comprises the steps:

[0041] (1) Add 60g of epichlorohydrin, 100g of diethylenetriamine, and 100g of diallylamine into a round-bottomed flask equipped with a water separator and a condenser tube, mix and heat to 50°C, and the inside of the water separator The amount of water no longer increases;

[0042] (2) Weigh 3g of oxidizing agent and dissolve the oxidizing agent according to the mass ratio of oxidizing agent and water of 1:10 to obtain the oxidizing agent solution; weigh 3g of reducing agent and dissolve the reducing agent according to the mass ratio of reducing agent and water of 1:10, namely to obtain a reducing agent solution;

[0043] (3) Heat the temperature to 60°C, add 3.3g of oxidizing agent solution and 3.3g of reducing agent solution to the reaction system, after 0.5h, add 29.7g of oxidizing agent solution and 29.7g of reducing agent solution dropwise at 70°C for 3...

Embodiment 3

[0046] The synthetic method of novel environment-friendly chlorine-resistant color-fixing agent comprises the steps:

[0047] (1) Add 60g of epichlorohydrin, 100g of diethylenetriamine, and 100g of diallylamine into a round-bottomed flask equipped with a water separator and a condenser tube, mix and heat to 50°C, and the inside of the water separator The amount of water no longer increases;

[0048](2) Weigh 3g of oxidizing agent and dissolve the oxidizing agent according to the mass ratio of oxidizing agent and water of 1:10 to obtain the oxidizing agent solution; weigh 3g of reducing agent and dissolve the reducing agent according to the mass ratio of reducing agent and water of 1:10, namely to obtain a reducing agent solution;

[0049] (3) Heat the temperature to 60°C, add 3.3g of oxidizing agent solution and 3.3g of reducing agent solution to the reaction system, after 0.5h, add 29.7g of oxidizing agent solution and 29.7g of reducing agent solution dropwise at 75°C for 3h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com