Alginate fiber and preparation method thereof

A seaweed fiber and fiber technology, applied in the field of seaweed fiber and its preparation, can solve problems such as difficulty in dyeing seaweed fiber, and achieve the effects of bright color, high soaping fastness and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

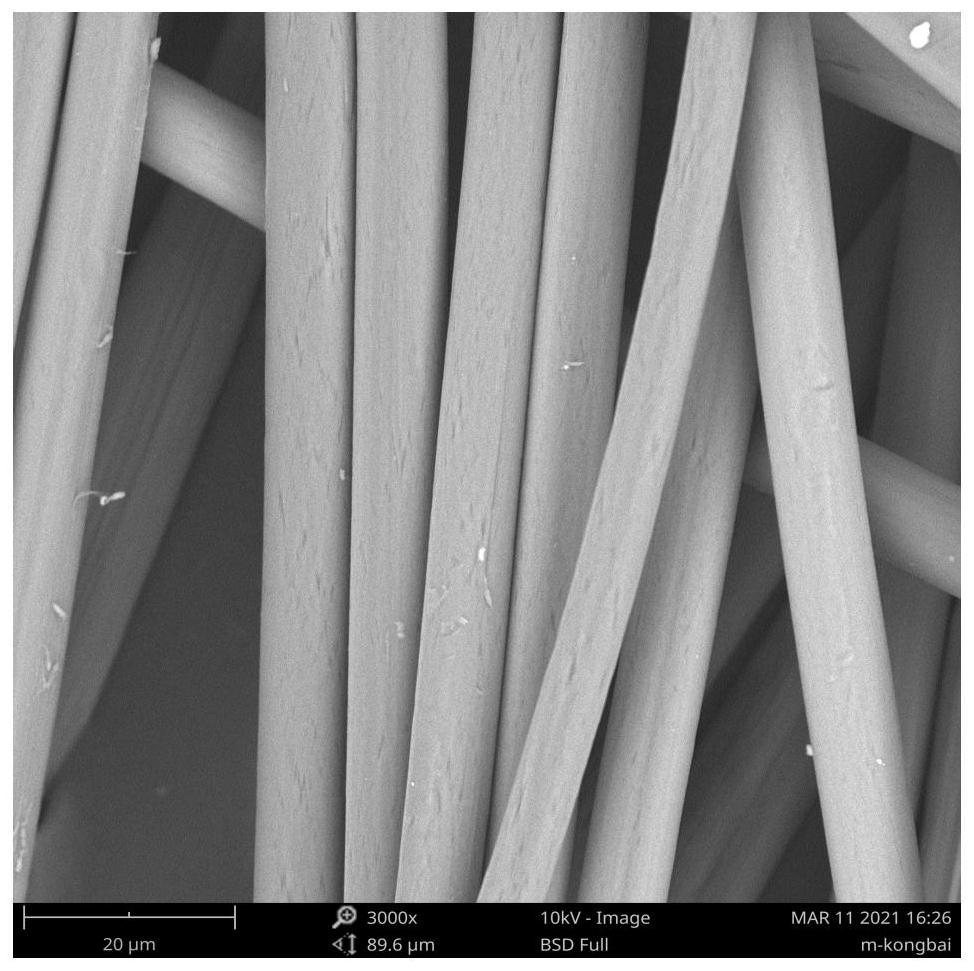

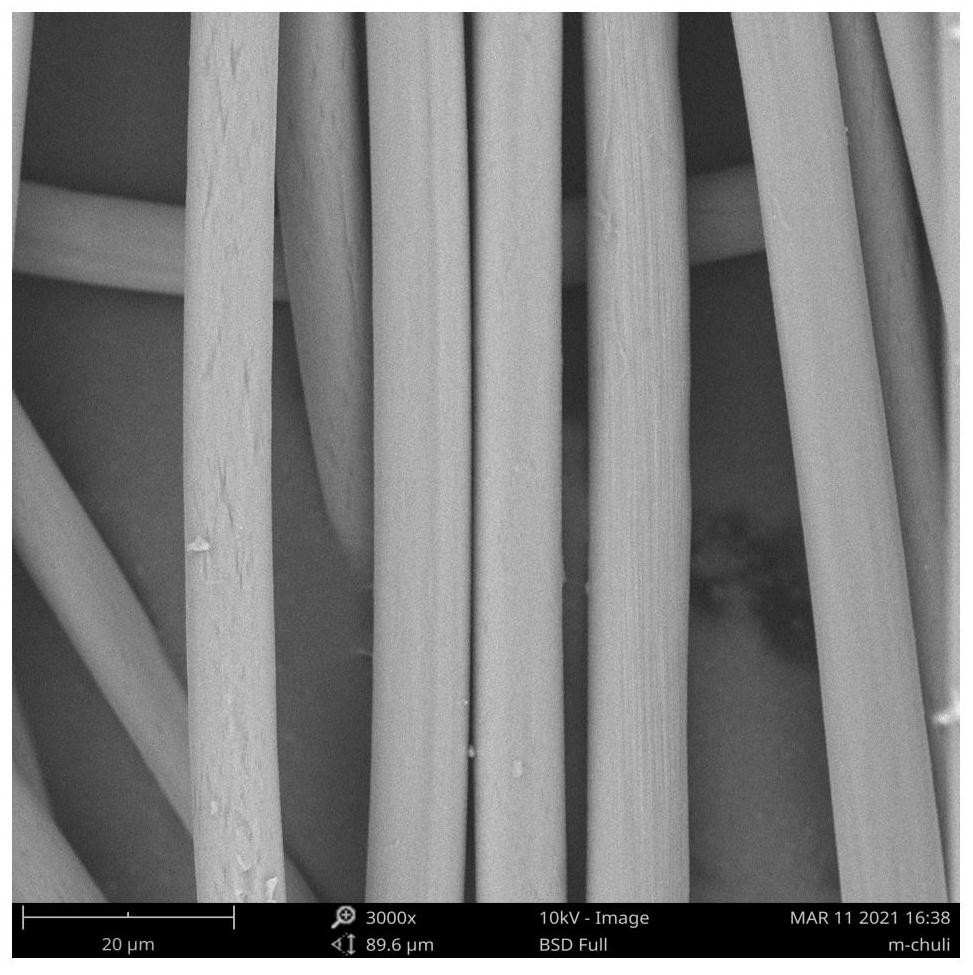

Image

Examples

preparation example Construction

[0046] The embodiment of the present application provides a preparation method of seaweed fiber, comprising:

[0047] S10. Using raw materials including sodium alginate to prepare spinning solution;

[0048] S20. Extruding the spinning solution obtained in S10 to a coagulation bath for coagulation and molding to obtain primary fibers;

[0049] S30. stretching and washing the primary fibers obtained in S20 to obtain seaweed fibers;

[0050] S40. Immersing the seaweed fibers obtained in S30 into a treatment agent for post-treatment;

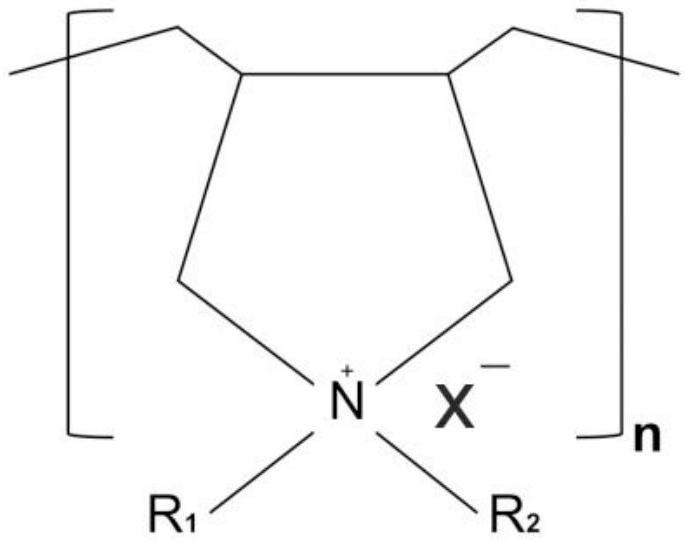

[0051] Wherein, at least one or all three of the raw material in S10, the coagulation bath in S20 and the treatment agent in S30 include a five-membered ring quaternary ammonium salt polymer.

[0052] In the above-mentioned embodiments, the seaweed fibers of the embodiments of the present application can be used to prepare seaweed fiber blended fabrics, and the seaweed fiber blended fabrics are blended fabrics of seaweed fibers and one or more othe...

Embodiment 1

[0105] (1) 40 g of sodium alginate and 1 g of five-membered ring quaternary ammonium salt polymer modifier were formulated into 1000 g of a solution.

[0106] (2) prepare the five-membered ring quaternary ammonium salt polymer modifier solution coagulation bath of the calcium chloride+1% of mass percent 5%, and regulate the coagulation bath pH value to 5 with hydrochloric acid, after the spinning solution is left standing for degassing Extruded into a coagulation bath aqueous solution at 40°C for coagulation and molding, and then stretched and rinsed.

[0107] (3) Dissolve 1g of the five-membered ring quaternary ammonium salt polymer modifier in water to form 1000g of soaking solution; contact the seaweed fiber prepared in step (2) with the soaking solution at 30°C for 20 minutes, and the soaking is completed After washing and drying, post-treatment cross-linked seaweed fibers are obtained.

Embodiment 2

[0109] (1) Dissolve 100g of sodium alginate in water to make a 2000g solution.

[0110] (2) prepare the five-membered ring quaternary ammonium salt polymer modifier solution coagulation bath of the calcium chloride+1.5% of mass percent 6%, and regulate the coagulation bath pH value to 6 with hydrochloric acid, after the spinning solution is left standing for degassing Extruded into a coagulation bath aqueous solution at 40°C for coagulation and molding, after drawing and washing;

[0111] (3) Dissolve 6g of the five-membered ring quaternary ammonium salt polymer modifier in water to form 1000g of soaking solution; contact the seaweed fiber prepared in step (2) with the soaking solution at 40°C and soak for 10 minutes, and the soaking is completed After washing and drying, post-treatment cross-linked seaweed fibers are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com