Alginate fiber and dyeing method thereof

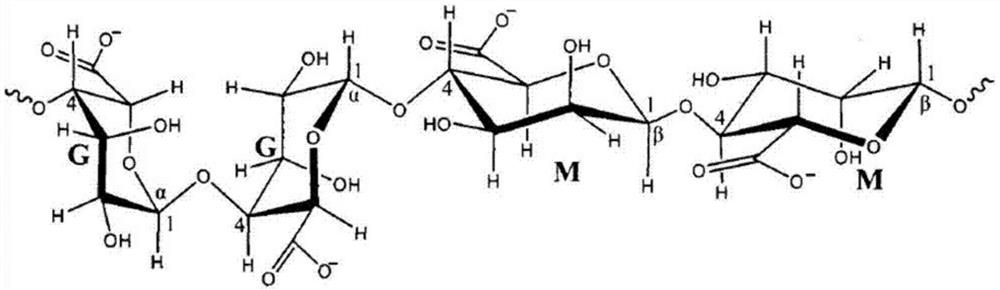

A technology of seaweed fiber and dyeing method, applied in the direction of dyeing method, textile and papermaking, etc., can solve the problems of difficulty in dyeing seaweed fiber, and achieve the effect of bright color, good fastness and good dyeing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

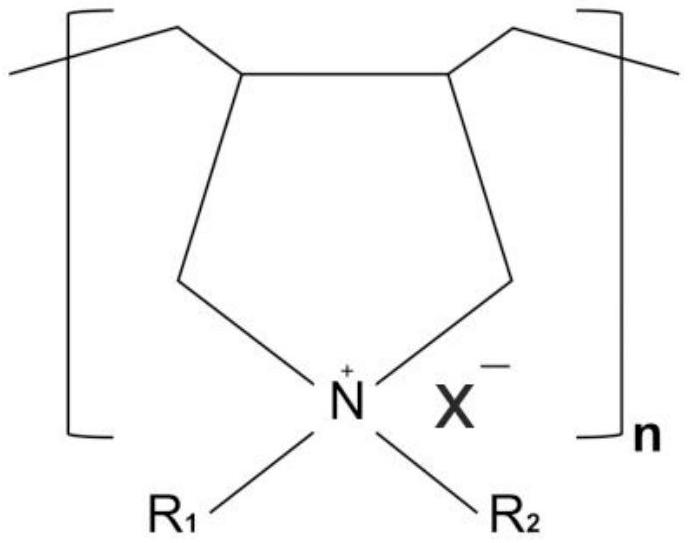

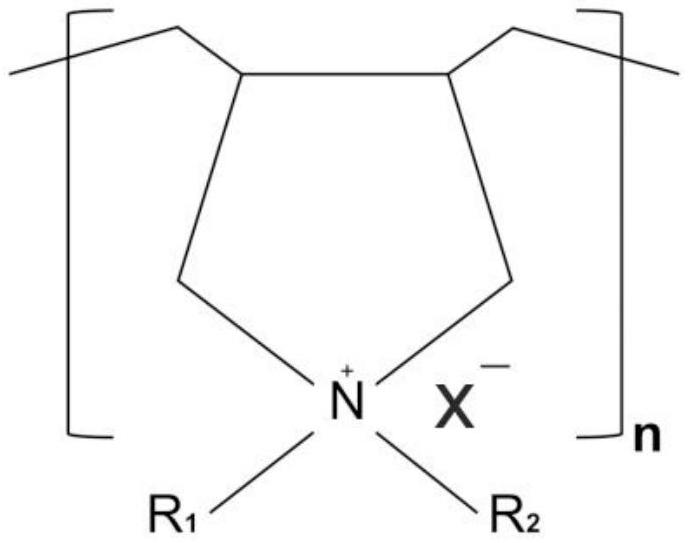

Embodiment 1

[0120] Prepare a five-membered ring quaternary ammonium salt polymer solution with a mass percentage of 1%, put the seaweed fiber to be dyed into the above-mentioned modifier aqueous solution according to the bath ratio of 1:20, shake it at 20°C for 10 minutes, and then rinse it for use. Weigh the direct scarlet 4BS according to 3% of the seaweed fiber mass, prepare the dye liquor according to the bath ratio of 1:20, wait for the temperature of the dye liquor to rise to 40°C, put the pretreated seaweed fiber into the dye liquor, and then raise the temperature of the dye liquor To 80 ℃, dyeing treatment for 40 minutes. Then prepare a five-membered ring quaternary ammonium salt polymer solution with a concentration of 1 g / l as a color-fixing solution, and perform color-fixing according to a liquor ratio of 1:30. Put the dyed seaweed fiber into the above-mentioned color-fixing agent aqueous solution, fix the color at 60°C for 30 minutes, then soak the seaweed fiber after the colo...

Embodiment 2

[0122] Prepare a five-membered ring quaternary ammonium salt polymer solution with a mass percentage of 3%, put the seaweed fiber to be dyed into the above-mentioned modifier aqueous solution according to the bath ratio of 1:30, shake it at 30°C for 20 minutes, and then rinse it for use. Weigh Acid Blue 80 according to 3% of the seaweed fiber mass, prepare a dye liquor according to a bath ratio of 1:20, wait for the temperature of the dye liquor to rise to 30°C, put the pretreated seaweed fiber into the dye liquor, and then raise the temperature of the dye liquor To 95 ℃, dyeing treatment for 60 minutes. Then prepare a five-membered ring quaternary ammonium salt polymer solution with a concentration of 1 g / l as a color-fixing solution, and perform color-fixing according to a liquor ratio of 1:30. Put the dyed seaweed fiber into the above-mentioned color-fixing agent aqueous solution, fix the color at 60°C for 30 minutes, then soak the seaweed fiber after the color-fixation tre...

Embodiment 3

[0124] Prepare a 5-membered ring quaternary ammonium salt polymer solution with a mass percentage of 5%, put the seaweed fiber to be dyed into the above-mentioned modifier aqueous solution according to the bath ratio of 1:40, shake it at 30°C for 30 minutes, and then rinse it for use. Weigh reactive yellow KN-R according to 3% of the mass of seaweed fiber, and prepare a dye solution according to a bath ratio of 1:20. When the temperature of the dye solution rises to 30°C, put the pretreated seaweed fiber into the dye solution, and then put the dye solution into the dye solution. The temperature of the liquid was raised to 60° C., and the dyeing treatment was carried out for 50 minutes. Then prepare a five-membered ring quaternary ammonium salt polymer solution with a concentration of 2 g / l as a color-fixing solution, and perform color-fixing according to a bath ratio of 1:30. Put the dyed seaweed fiber into the above-mentioned color-fixing agent aqueous solution, fix the color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| soaping fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com