Disperse dye, and preparation method and application thereof

A disperse dye and hydrogen-based technology, applied in dyeing methods, azo dyes, organic dyes, etc., can solve the problems of large specific surface area of fine-denier polyester fibers, difficulty in obtaining high washing fastness, and reduced washing fastness, achieving improved Effects of soaping fastness, color fastness improvement and water solubility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0048] (1), preparation of diazonium salt:

[0049] In a three-necked flask with a stirrer, 4-chlorosulfonic acid phenylacetamide (12.0g), potassium fluoride (180g) and 240 ml of water were mixed and dissolved, stirred and refluxed for 3h, then added to an ice bath for precipitation, Wash the cooled object with tap water at 40°C with a pH value of 4 to 5, and collect the precipitate. 0.1 mole of 4-fluorosulfonanilide precipitate was dissolved in 35 ml of concentrated hydrochloric acid and 350.0 ml of water, and 0.1 mole of sodium nitrite was added in a calcium chloride ice bath at a temperature of -5°C to 5°C. After diazotization for 4-5 hours, add sodium acetate to adjust the pH value to pH 5-6, filter and wash.

[0050] (2), coupling reaction:

[0051] Add 0.1 mole diazonium salt solution to the solution containing 0.1 mole coupling component, 500ml methanol and 500g ice bath, react for 4-5 hours, then adjust the pH value of the diazonium solution to pH 5-6 by adding sodiu...

Embodiment 2-5

[0053] The preparation method is the same as in Example 1, the difference is that: change the diazotization reagent, the diazotization reaction temperature, the molar ratio of the diazonium compound to the diazotization reagent reaction substance, and the molar ratio of the diazotization salt to the coupling reagent reaction substance to obtain The different disperse dyes are shown in the table below.

[0054] Table 1,

[0055]

[0056] Product Confirmation:

[0057] Compound Ⅰ-1:

[0058] Chemical formula:

[0059]

[0060] Physical and chemical parameters: brown solid particles, purple-red solution in toluene solvent, maximum absorption wavelength 523nm.

[0061] Confirmation of structure:

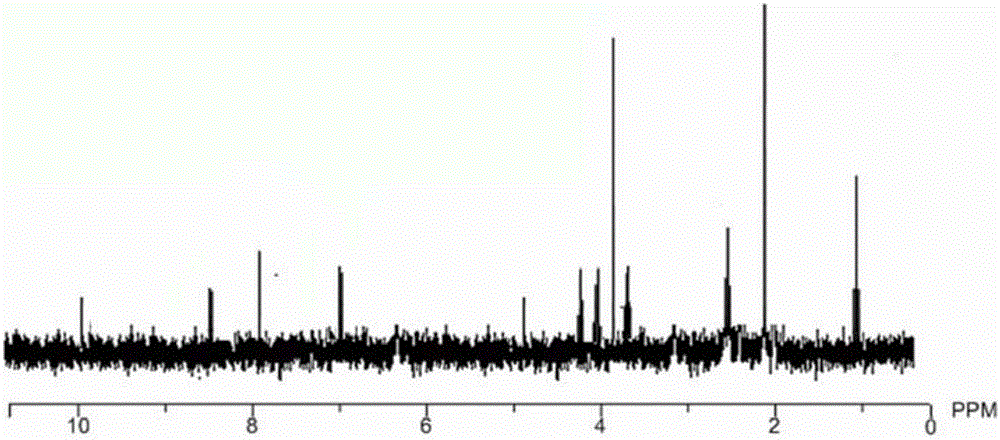

[0062] 1 H-NMR (DMSO-d6): δ=7.05(d, J=7.30Hz, 1H, Ar-H), 8.00(d, J=2.50Hz, 1H, Ar-H), 8.50(d, J=2.50 Hz,1H,Ar-H),3.93-4.20(m,2H,CH 2 ), 3.86 (d, 3H, J=2.80, OCH 3 ),2.62(t,2H,J=3.60Hz,3.60Hz,CH2 COO),2.03(s,3H,CH 3 CO),1.07(m,3H,CH 2 CH 3 ), 4.85 (s, 1H, OH), 10.25 (s, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com