Environmentally-friendly textile printing ink and preparation method thereof

An environmentally friendly, textile technology, applied in ink, textile and papermaking, dyeing and other directions, can solve problems such as threats to the health of employees, threats to human health, easy breeding of bacteria, etc., to enhance environmental protection, low boiling point, and low air pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

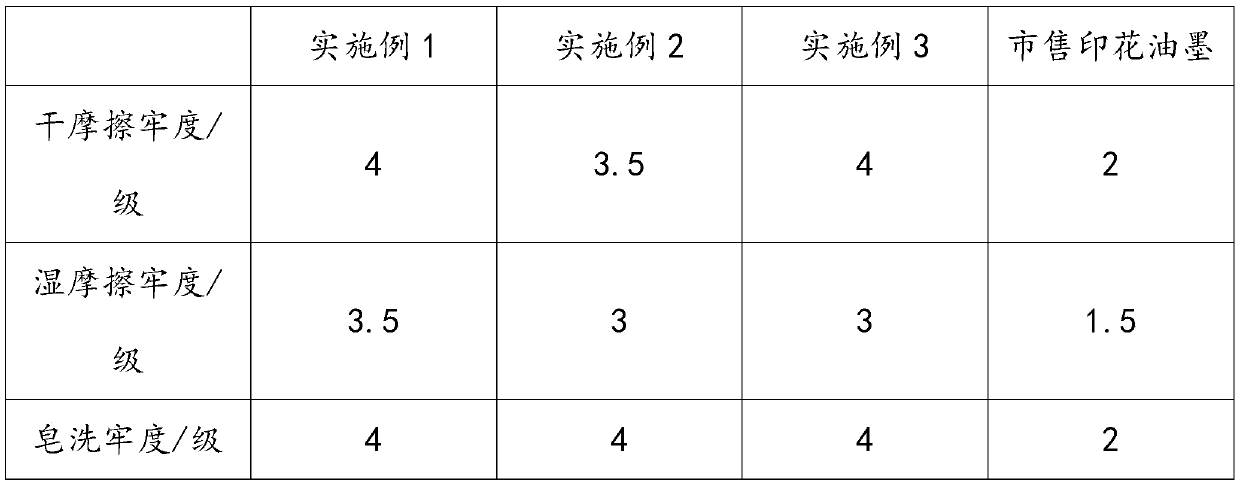

Examples

preparation example Construction

[0061] The preparation method of environment-friendly textile printing ink comprises the steps:

[0062] Step S1, adding alcohol-soluble color paste and plasticizer into a high-speed dispersion tank, stirring at 2000r / min for 5-6min, to obtain mixture A;

[0063] Step S2, add the solvent into the high-speed dispersion tank, slowly add the polyurethane binder under the condition of stirring at 1500r / min, and keep stirring at 1500r / min for 10-12min after adding, to obtain the mixture B;

[0064] Step S3, mix mixture A and mixture B, put them into a high-speed dispersion tank, stir at 1000r / min for 3-4min, keep stirring at 1000r / min, add antibacterial agent, stabilizer and rheological additive in sequence, and continue stirring after adding Disperse for 20-24min;

[0065] Step S4, transfer the above mixture to a sand mill for grinding until the fineness is less than 5m, to obtain the environment-friendly textile printing ink.

Embodiment 1

[0067] Environmentally friendly textile printing ink, made of the following raw materials in parts by weight: 26 parts of polyurethane binder, 38 parts of alcohol-soluble color paste, 2 parts of antibacterial agent, 20 parts of solvent, 10 parts of trioctyl trimellitate, Zn / Sn 1 part of composite stabilizer, 4 parts of modified organic urea solution;

[0068] The preparation method of environment-friendly textile printing ink comprises the steps:

[0069] Step S1, adding alcohol-soluble color paste and trioctyl trimellitate into a high-speed dispersion tank, stirring at 2000r / min for 5min, to obtain mixture A;

[0070] Step S2, add the solvent into the high-speed dispersion tank, slowly add the polyurethane binder under the condition of stirring at 1500r / min, and keep stirring at 1500r / min for 10min after adding, to obtain the mixture B;

[0071] Step S3, mix mixture A and mixture B, put them into a high-speed dispersion tank, stir at 1000r / min for 3min, and add antibacterial...

Embodiment 2

[0074] Environmentally friendly textile printing ink is made of the following raw materials in parts by weight: 29 parts of polyurethane binder, 41 parts of alcohol-soluble color paste, 2.5 parts of antibacterial agent, 25 parts of solvent, 11 parts of triethylene glycol diisocaprylate, Zn / 1.5 parts of Sn composite stabilizer, 5 parts of castor oil derivative thixotropic agent;

[0075] The preparation method of environment-friendly textile printing ink comprises the steps:

[0076] Step S1, adding the alcohol-soluble color paste and triethylene glycol diisocaprylate into a high-speed dispersion tank, and stirring at 2000r / min for 5.5min to obtain mixture A;

[0077] Step S2, add the solvent into the high-speed dispersion tank, slowly add the polyurethane binder under the condition of stirring at 1500r / min, and keep stirring at 1500r / min for 11min after adding, to obtain the mixture B;

[0078] Step S3, mix mixture A and mixture B, put into a high-speed dispersion tank, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com