Synthetic method and application of macromolecular activated flame retardant

A synthesis method and flame retardant technology are applied in the synthesis field of polyvinyl alcohol phosphonate ammonium flame retardant, which can solve the problems of cotton fabric being inflammable, easy to cause and spread fire, easy to be washed off, etc. The effect of washing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

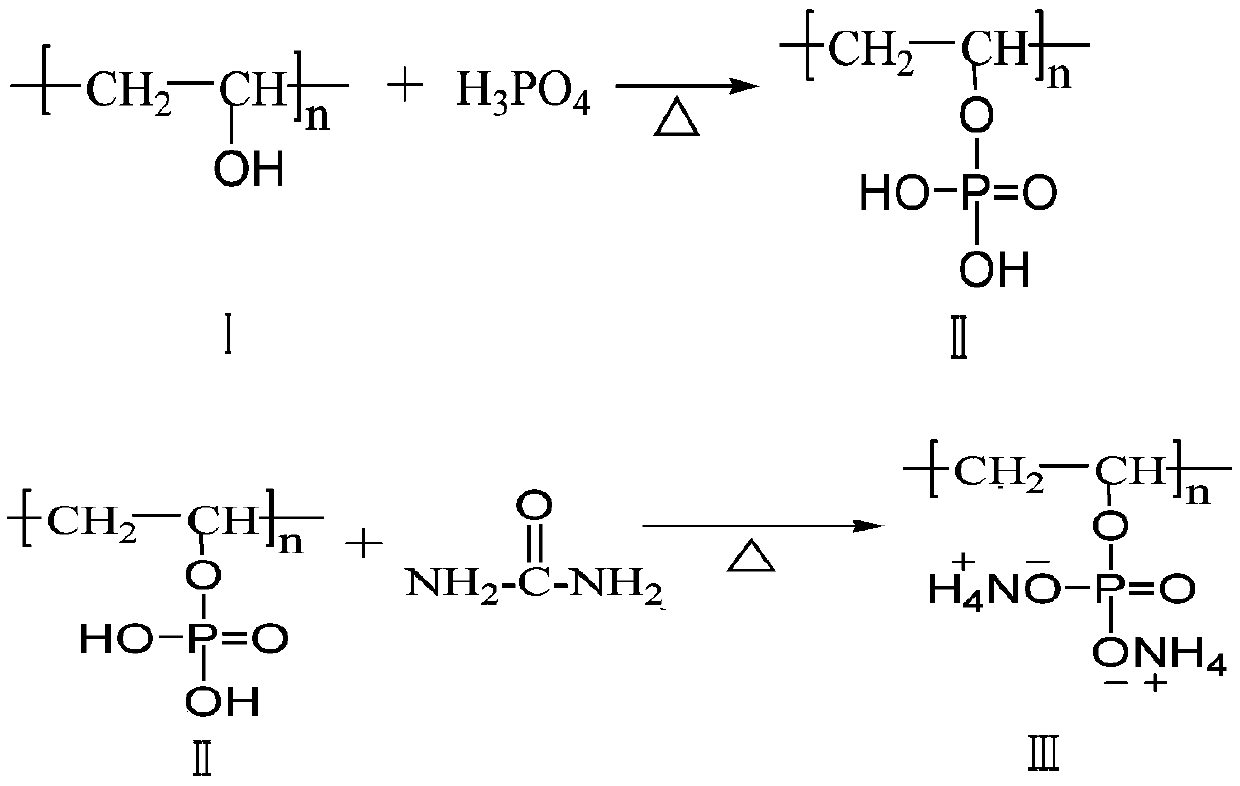

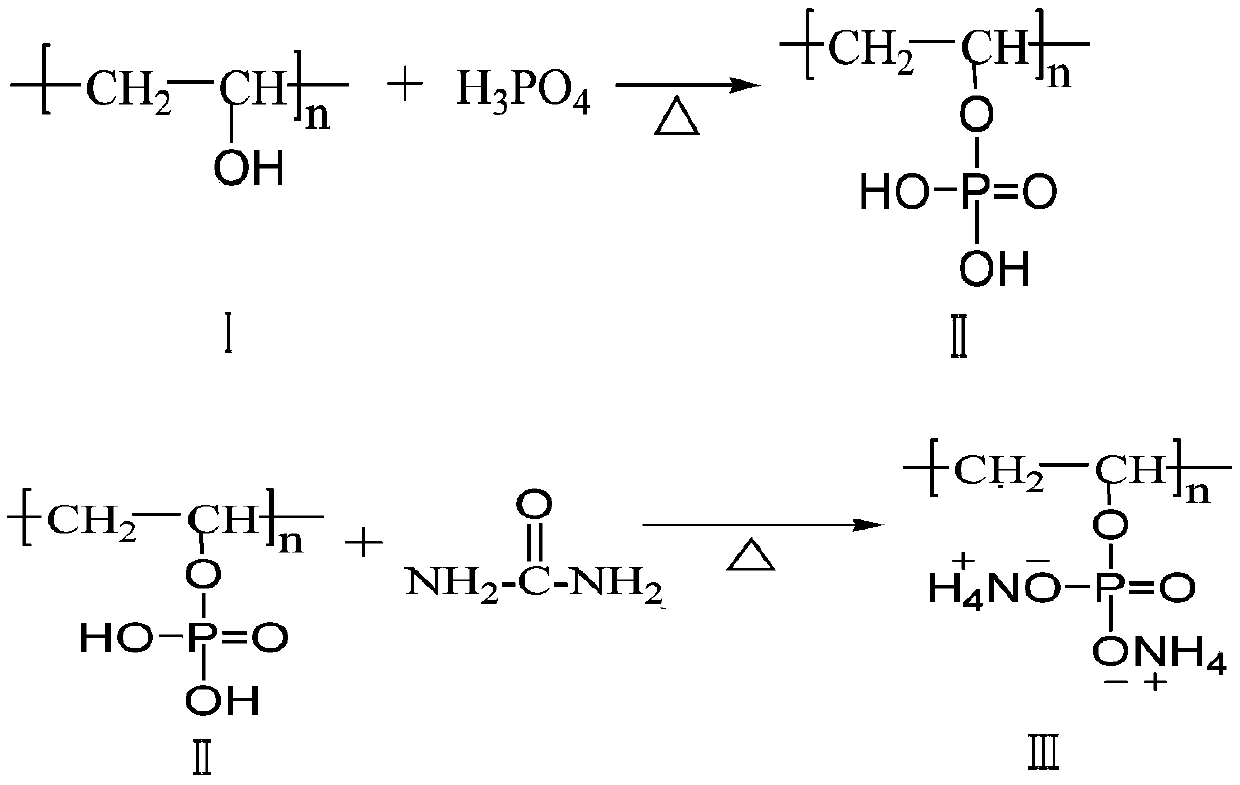

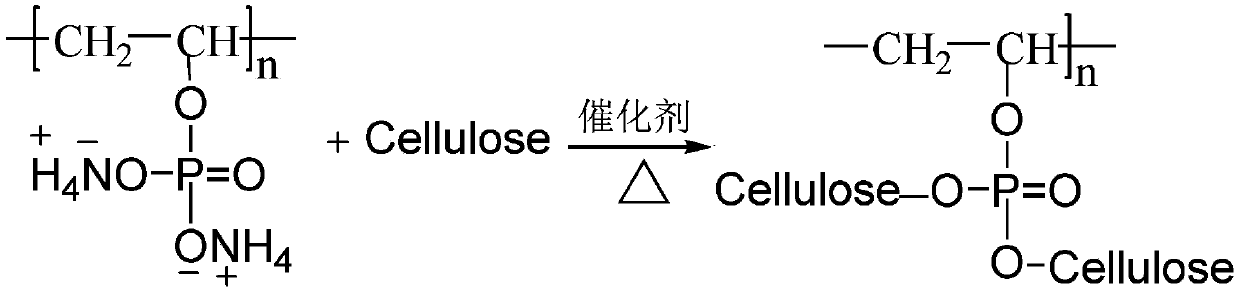

Method used

Image

Examples

Embodiment 1

[0041] 12 grams of polyvinyl alcohol (I) was added to a 500mL beaker, 88mL of water was added, and then 19.1mL of phosphoric acid 19.1mL with a mass concentration of 85% was added, and heated for 6 hours on a 1KW electric furnace equipped with a mechanical stirrer to prepare poly Vinyl alcohol phosphonate (II); then add 20 mL of water and 16.1 g of urea, continue heating for 3 hours, and the pH of the thick liquid is 5-6. Ammonium polyvinyl phosphonate (III) is obtained.

[0042] Add water to the prepared polyvinyl alcohol phosphonate ammonium (III) to prepare 60 mL of polyvinyl alcohol phosphonate ammonium (III) solution, then add 3 grams of dicyandiamide, soak 10 grams of cotton fabric in it, and the temperature is 50 ° C , time 10 minutes. Take out the cotton fabric, dry it with a paddle car, the liquid retention rate is about 100%, and then bake it on a 190°C setting machine for 6 minutes. Then wash and dry to prepare polyvinyl phosphonate ammonium branch cotton fabric (...

Embodiment 2

[0045] 18 grams of polyvinyl alcohol (I) are joined in the beaker of 500mL, add 120mL water, mass concentration is 85% phosphoric acid 16.6mL, is equipped with the electric stove of mechanical stirrer of 1KW and heats 6 hours, prepares polyvinyl alcohol Phosphonate (II); then add 30 mL of water and 21.8 g of urea, continue heating for 3 hours, and the pH of the thick liquid is 5-6. Ammonium polyvinyl phosphonate (III) is obtained.

[0046] Add water to the prepared polyvinyl alcohol phosphonate ammonium (III) to prepare 90 mL of polyvinyl alcohol phosphonate ammonium (III) solution, then add 4.5 grams of dicyandiamide, and soak 15 grams of cotton fabric in it at a temperature of 50 ° C , time 10 minutes. Take out the cotton fabric, dry it with a paddle car, the liquid retention rate is about 100%, and then bake it on a 200°C setting machine for 3 minutes. Then wash and dry to prepare polyvinyl phosphonate ammonium branch cotton fabric (IV).

[0047] Washing with 1A conditio...

Embodiment 3

[0049] 24 grams of polyvinyl alcohol (I) were added to a 500mL beaker, 170mL of water was added, and 40mL of phosphoric acid with a mass concentration of 85% was heated for 6 hours on a 1KW electric furnace equipped with a mechanical stirrer to prepare polyvinyl alcohol phosphine Ester (II); then add 40mL of water and 40g of urea, continue heating for 3 hours, the pH of the thick liquid is 5-6. Ammonium polyvinyl phosphonate (III) is obtained.

[0050] Add water to the prepared polyvinyl alcohol phosphonate ammonium (III) to prepare a 120mL polyvinyl alcohol phosphonate ammonium (III) solution, then add 6 grams of dicyandiamide, and soak 20 grams of cotton fabric in it at a temperature of 50°C , time 10 minutes. Take out the cotton fabric, dry it with a paddle car, the liquid retention rate is about 100%, and then bake it on a 185°C setting machine for 6 minutes. Then wash and dry to prepare polyvinyl phosphonate ammonium branch cotton fabric (IV).

[0051] Washing with the 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com