Active cationic modifier and preparation method thereof and method for modifying silk fiber

A technology of active cationic and silk fibers, applied in dyeing, textiles and papermaking, etc., can solve the problems of inability to dye dark colors, unemployment of workers, shutdown of production, etc., and achieve high soaping fastness, high grafting fastness, improved Sexually efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

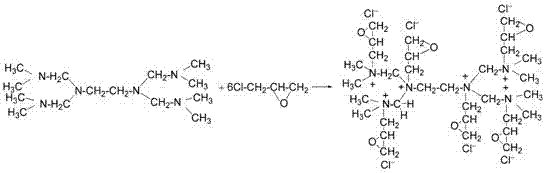

[0029] Add 450ml of water, 15ml of ethylenediamine, and 67ml of formaldehyde solution with a mass concentration of 40% to a 1000ml round bottom flask, place it in a constant temperature water bath at 60°C, and stir it mechanically for 30 minutes; after cooling to 35°C, add 123ml of Aqueous solution of dimethylamine with a concentration of 33% was reacted for 1h; then the temperature was raised to 40°C, 106ml of epichlorohydrin was added, and reacted for 1.5h. Ethylenediaminetetramethylenetetra(N,Ndimethyl)hexa(2,3 epoxypropyl) ammonium chloride (XS) modifier.

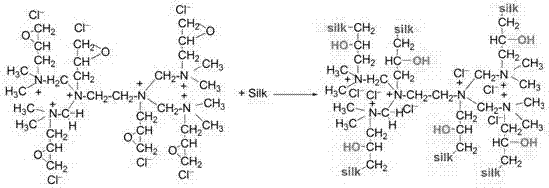

[0030] The prepared XS modifier was formulated into an aqueous solution with a mass concentration of 5%, and the degummed silk fiber was immersed in the XS aqueous solution at room temperature, with a bath ratio of 1:10, soaked for 10 minutes, and then the silk fiber was taken out and rolled in a rolling mill. Press, the rolling pressure is 0.3MPa, and the liquid carrying rate is 100%. Then the silk fibers were put int...

example 2

[0033] Add 300ml of water, 10ml of ethylenediamine, and 45ml of formaldehyde solution with a mass concentration of 40% to a 1000ml round bottom flask, place it in a constant temperature water bath at 40°C, and stir it mechanically for 30min; after cooling to 35°C, add 82ml of Aqueous solution of dimethylamine with a concentration of 33% was reacted for 1h; then the temperature was raised to 40°C, 70ml of epichlorohydrin was added, and reacted for 1.5h. Ethylenediaminetetramethylenetetra(N,Ndimethyl)hexa(2,3 epoxypropyl) ammonium chloride (XS) modifier.

[0034] The prepared XS modifier was formulated into an aqueous solution with a mass concentration of 10%, and the degummed silk fiber was immersed in the XS aqueous solution at room temperature, with a bath ratio of 1:10, soaked for 10 minutes, and then the silk fiber was taken out and rolled in a padding machine. Press, the rolling pressure is 0.3MPa, and the liquid carrying rate is 100%. Then put the silk fibers into an ove...

example 3

[0037] Add 360ml of water, 12ml of ethylenediamine, and 54ml of formaldehyde solution with a mass concentration of 40% to a 1000ml round bottom flask, place it in a constant temperature water bath at 50°C, and stir it mechanically for 30min; after cooling to 35°C, add 98ml of Aqueous solution of dimethylamine with a concentration of 33% was reacted for 1 hour; then the temperature was raised to 40°C, 85ml of epichlorohydrin was added, and the reaction was carried out for 1.5 hours. epoxypropyl) ammonium chloride (XS) modifier.

[0038] The prepared XS modifier was formulated into an aqueous solution with a mass concentration of 15%, and the degummed silk fiber was immersed in the XS aqueous solution at room temperature, with a bath ratio of 1:10, soaked for 10 minutes, and then the silk fiber was taken out and rolled in a rolling mill. Press, the rolling pressure is 0.3MPa, and the liquid carrying rate is 100%. Then the silk fibers were put into an oven and baked at 120° C. f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com