Detergent and preparation method thereof

A technology for cleaning lotion and polyvinylpyrrolidone is applied in the field of cleaning lotion and its preparation, and can solve the problems of environmental pollution, energy consumption, high chromaticity of lotion, insufficient color fastness and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

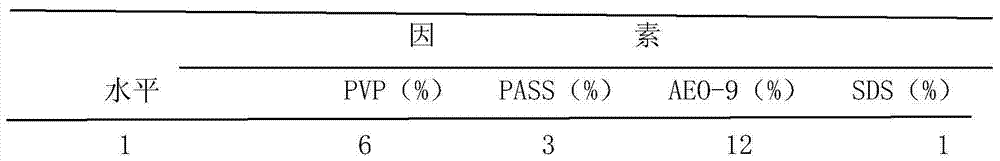

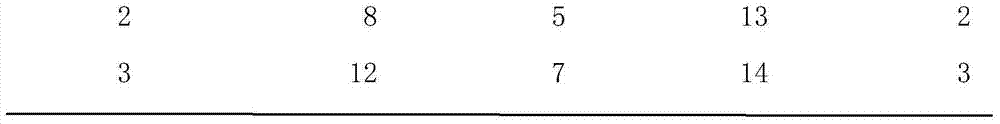

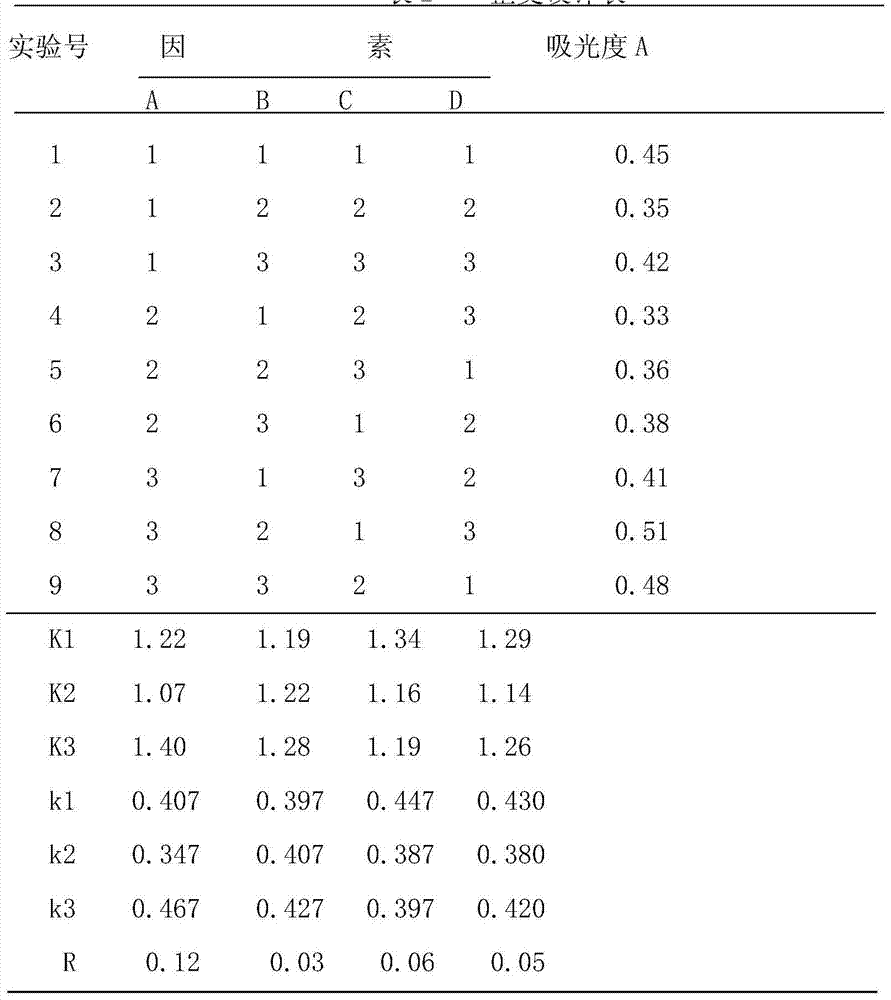

Method used

Image

Examples

Embodiment 1

[0069] Formula: polyvinyl pyrrolidone PVP12%, sodium polyacrylate PAAS5%, fatty alcohol polyoxyethylene ether AEO-912%, sodium lauryl sulfate SDS3%, sorbitan laurate PEG-805%, Yu The amount is water.

[0070] Process: Add fatty alcohol polyoxyethylene ether AEO-9, sorbitan laurate PEG-80 and water in sequence according to the formula amount in the compounding kettle, heat up to 50°C and stir for 1 hour to dissolve; under vigorous stirring, Add polyvinylpyrrolidone PVP, sodium polyacrylate PAAS, and sodium dodecyl sulfate SDS to the above solution in sequence, and stir at 50°C for 1.5 hours to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com