Composite liquid reactive red dye

A reactive red dye and liquid technology, applied in the field of liquid reactive composite red dyes, can solve the problems of easy agglomeration or salting out of liquid reactive red dyes during storage, and achieve high soaping fastness, good storage stability and stable storage performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

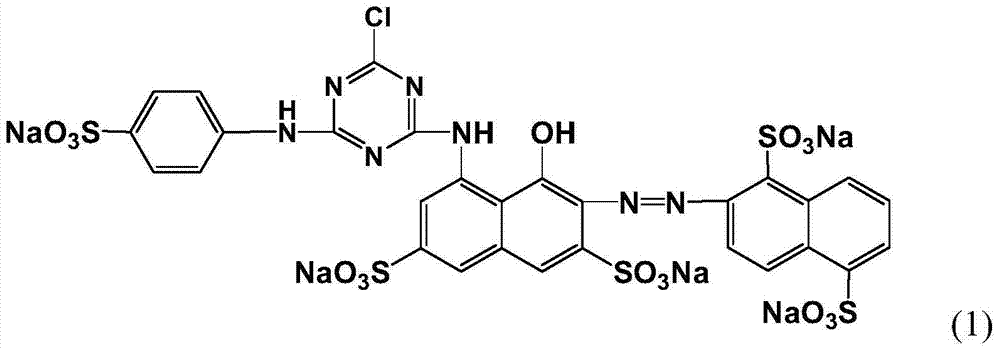

[0042]The preparation method of monomer A: 102 parts of cyanuric chloride and 3 parts of dispersant are beaten to powder in the presence of crushed ice, and 100 parts of 15% (mass concentration) sodium p-aminobenzenesulfonate solution is added for one condensation. Control pH=5-6, temperature 3-5°C; when the free amino group value is less than 1%, add 100 parts of dry product H acid, control temperature 30-35°C, pH=4-4.5, after the reaction is over, add ice and cool down to Around 25°C; Finally, carry out coupling reaction with 100 parts of diazonium salt of 1,5-disulfonic acid naphthylamine to obtain dye monomer A solution.

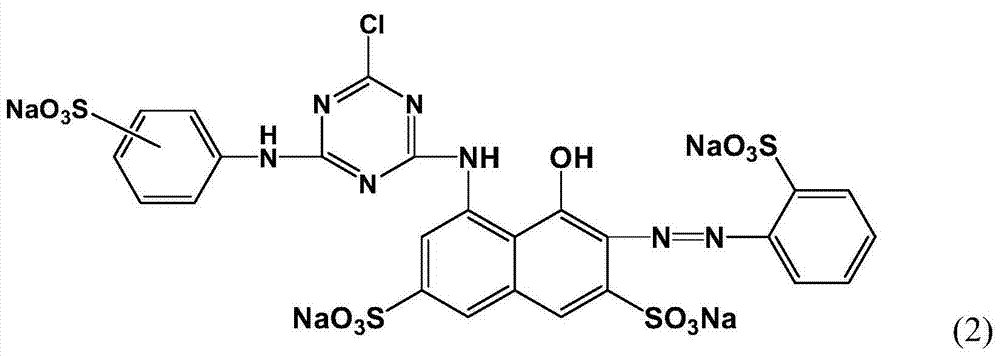

[0043] The preparation method of monomer B: 102 parts of cyanuric chloride and 3 parts of dispersing agent are beaten to powder in the presence of crushed ice, and 100 parts of 15% (mass concentration) H acid solution is added for condensation once, and the temperature is 6- 8°C, pH = 2-2.5, the liquid phase controls the primary condensation product puri...

Embodiment 1-13

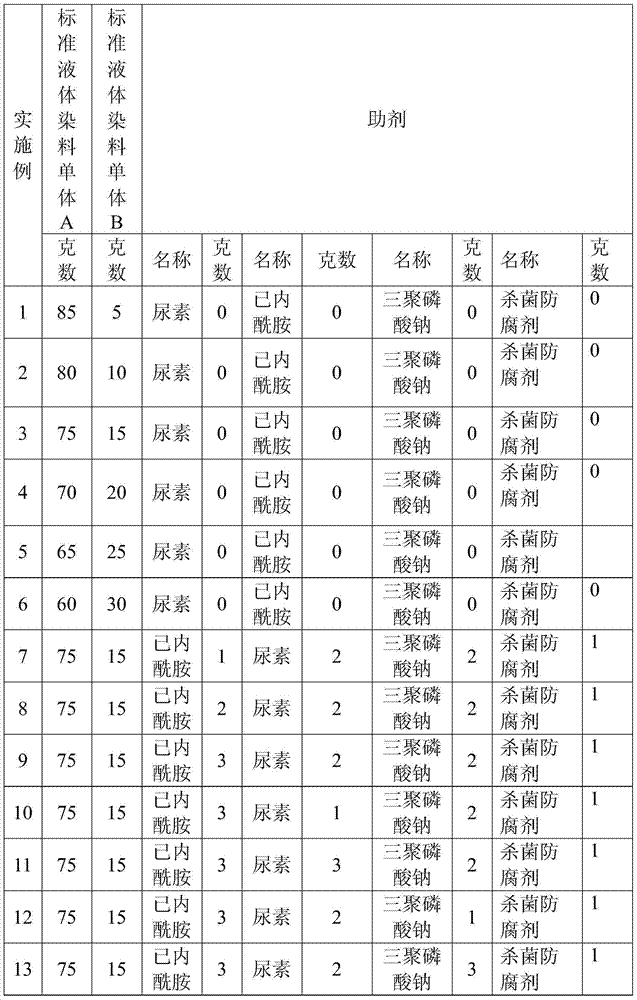

[0046] 60-80 parts of standard liquid dye monomer A as shown in formula (1); 10-30 parts of standard liquid dye monomer B as shown in formula (2) (in each of the following examples, monomer B mediosite and The para position determines the highest solubility index by adjusting different ratios, wherein the ratio of the para position and the meta position of monomer B in Examples 1 to 6 is 0.5:1; the para position and meta position of monomer B in Examples 7 to 9 The ratio of monomer B is 1.5:1; the ratio of para-position and meta-position of monomer B in Examples 9-13 is 2:1), select dye monomer A and dye monomer B to add additives at a ratio of 5:1 : 1-3 parts of urea, 1-3 parts of caprolactam, 1-3 parts of sodium tripolyphosphate, appropriate amount (generally 0.3%) of bactericidal preservative, prepared into liquid dye, the formula is shown in Table 1.

[0047] Table 1

[0048]

[0049] The reactive dyes prepared in the above examples are dyed with standard reactive dyes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com