Vegetable oil modified fluoride-containing water repellent finishing agent as well as preparation method and application thereof

A vegetable oil modification and water-repellent finishing technology, which is applied in the field of fluorine-containing water-repellent finishing agents and its preparation, can solve the problems of poor wearability of cellulose fibers, decreased hydrophilicity of cellulose fibers, and easy generation of static electricity in fabrics, etc., to achieve Low cost, improved water repellency, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

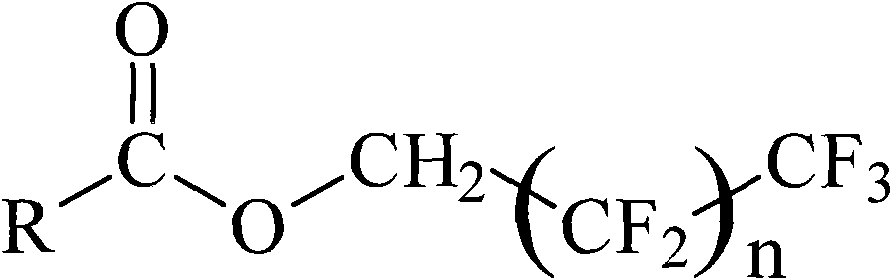

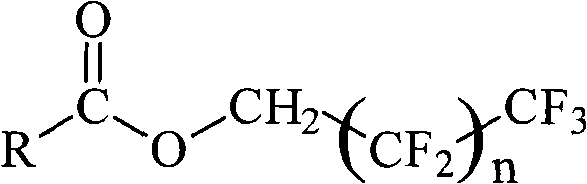

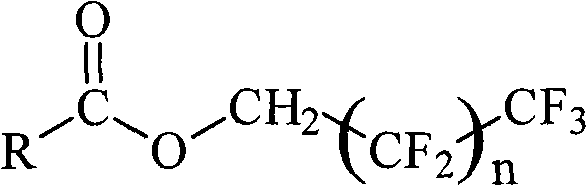

Image

Examples

Embodiment 1

[0028] (1) Add 35ml of 80°C hot water and 3.5g of sodium hydroxide to 20g of castor oil, dissolve with 15ml of hot water, heat in an 80°C water bath, stir, and let stand. An appropriate amount of sodium chloride is added to precipitate the mixture of sodium ricinoleate, sodium palmitate, sodium stearate, sodium oleate, sodium linoleate and sodium linolenate, and the glycerin is removed with the aqueous solution of sodium chloride.

[0029] (2) Dissolve the mixture of sodium ricinoleate, sodium palmitate, sodium stearate, sodium oleate, sodium linoleate and sodium linolenate prepared in step (1) in water, add an appropriate amount of sulfuric acid to acidify, pour into the liquid Stand in the funnel for stratification, and the upper layer is a mixture of ricinoleic acid, palmitic acid, stearic acid, oleic acid, linoleic acid and linolenic acid.

[0030] (3) 15.4 g of the mixture of ricinoleic acid, palmitic acid, stearic acid, oleic acid, linoleic acid and linolenic acid prepar...

Embodiment 2

[0033] The synthesis method of the palm oil and the finishing process on the cellulose fibers are basically the same as in Example 1. The finishing results showed that after finishing with palm oil-modified trifluoroethyl ester, the cellulose fibers obtained excellent water-repellent properties, while the whiteness and breaking strength decreased slightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com