Preparation method of anti-yellowing TPU and TPU protective film

A technology of yellowing resistance and protective film, applied in the field of TPU, can solve the problems of poor yellowing resistance, residual glue on the car paint surface, scratches on the car paint surface, etc., to enhance heat resistance, good protection effect, reduce The effect of dust adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention provides a kind of preparation method of anti-yellowing TPU, the preparation method of this anti-yellowing TPU comprises:

[0039] Step a1, put the isocyanate and the dihydroxy water repellent into the reaction vessel, raise the temperature to 85-95°C and stir for more than 0.5h;

[0040] Step a2, putting polyglycol, 1,4 butanediol, graphene, anti-yellowing agent, antioxidant and catalyst into the reaction vessel, and stirring for more than 1 hour;

[0041] Step a3, put the monohydroxyl water repellant into the reaction vessel, and stir for more than 0.5h;

[0042] Step a4. Bake the stirred material at a temperature of 75-85° C. for more than 10 hours to form an anti-yellowing TPU.

[0043] Among them, in step a1, the dihydroxy water-repellent agent participates in part of the chain extension, the purpose of which is to ensure that the main chain of TPU has sufficient water-repellent function; the addition of a single-hydroxyl water-repellent agen...

Embodiment 1

[0080] The present embodiment provides a kind of preparation method of TPU protective film, and this preparation method comprises:

[0081] The first stage, preparation of anti-yellowing TPU:

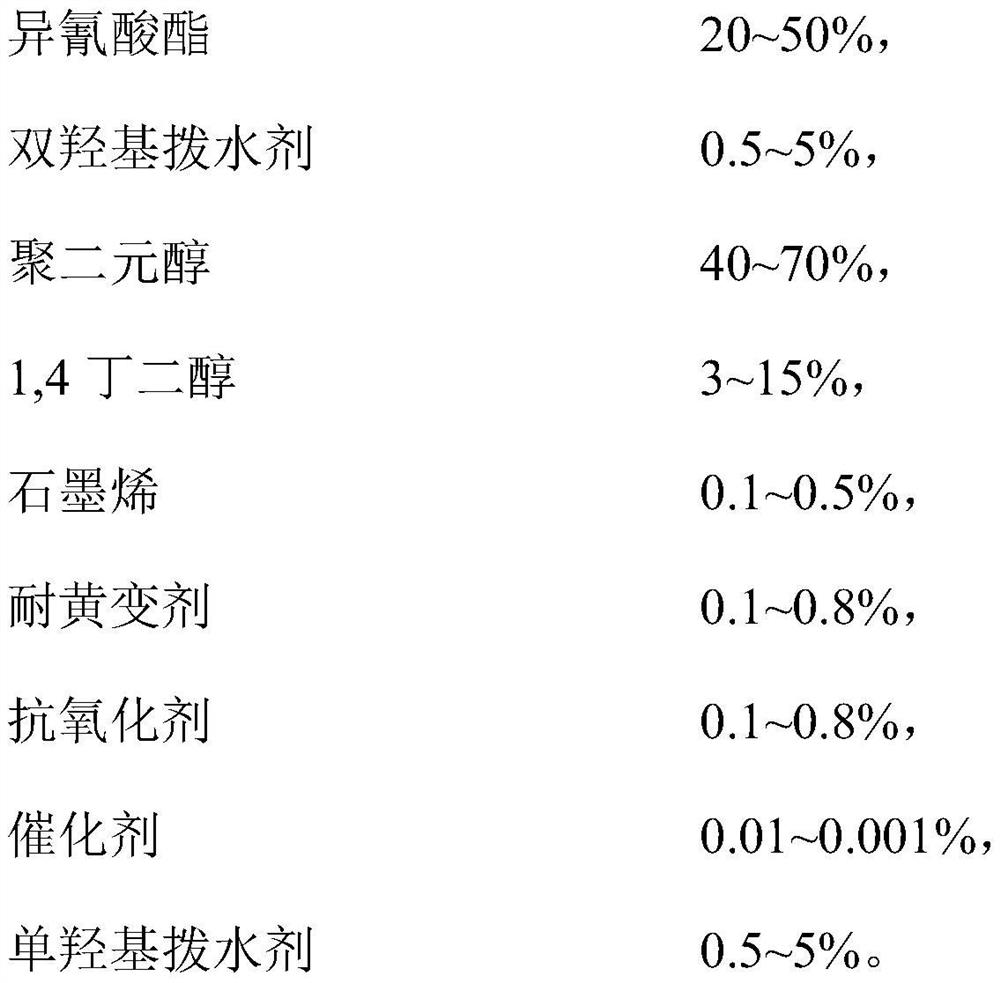

[0082] The weight of each component of anti-yellowing TPU is as follows:

[0083]

[0084] Step a1, put IPDI and PDS 1000 into the reaction vessel, raise the temperature to 90°C and stir for 1h;

[0085] Step a2, put PC 2000, 1,4-butanediol, graphene, UV-328, 1010 antioxidant and stannous octoate into the reaction vessel, and stir for 2 hours;

[0086] Step a3, put PMS 500 into the reaction vessel, and stir for 1 hour;

[0087] Step a4, baking the stirred material at a temperature of 80° C. for 14 hours to form an anti-yellowing TPU.

[0088] The second stage, preparation of anti-yellowing pressure-sensitive adhesive:

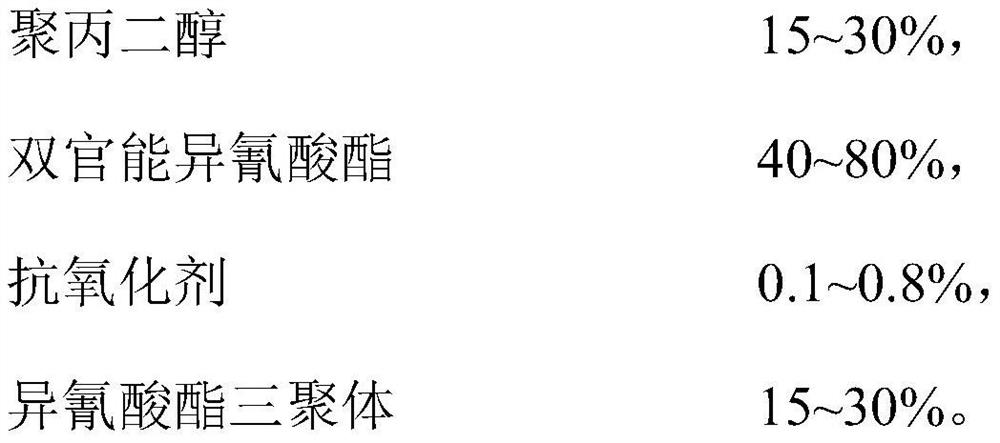

[0089] Prepare the first pressure-sensitive adhesive raw material, the weight of each component is:

[0090]

[0091] Step c1, put polypropylene glycol 2000, ...

Embodiment 2

[0103] The present embodiment provides a kind of preparation method of TPU protective film, and this preparation method comprises:

[0104] The first stage, preparation of anti-yellowing TPU:

[0105] The weight of each component of anti-yellowing TPU is as follows:

[0106]

[0107] Step a1, H 12 Put MDI and PDS 1000 into the reaction vessel, raise the temperature to 90°C and stir for 1h;

[0108] Step a2, put PTMEG 2000, 1,4-butanediol, graphene, UV-328, 1010 antioxidant and stannous octoate into the reaction vessel, and stir for 2 hours;

[0109] Step a3, put PMS 500 into the reaction vessel, and stir for 1 hour;

[0110] Step a4, baking the stirred material at a temperature of 80° C. for 14 hours to form an anti-yellowing TPU.

[0111] The second stage, preparation of anti-yellowing pressure-sensitive adhesive:

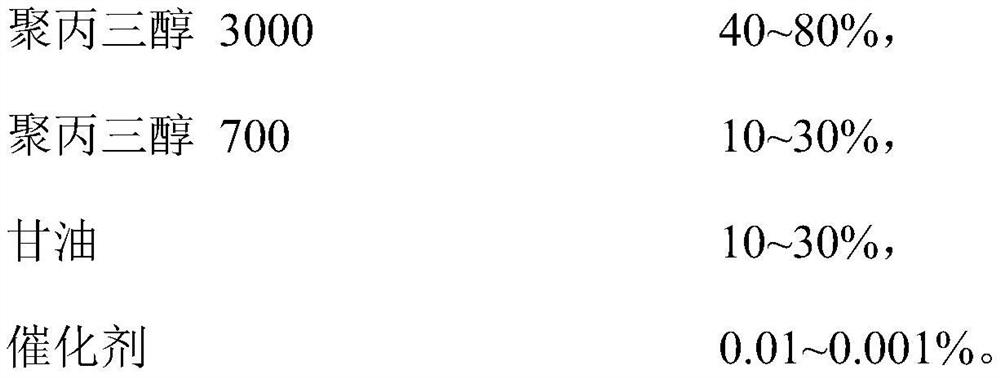

[0112] Prepare the first pressure-sensitive adhesive raw material, the weight of each component is:

[0113]

[0114] Step c1, put polypropylene glyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com