A preparation method of flame-retardant and water-repellent double-functional cotton fabric

A cotton fabric, water double technology, applied in the field of dyeing and finishing, to achieve the effect of easy operation, broad application prospects and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of flame-retardant cotton fabric, the steps are as follows:

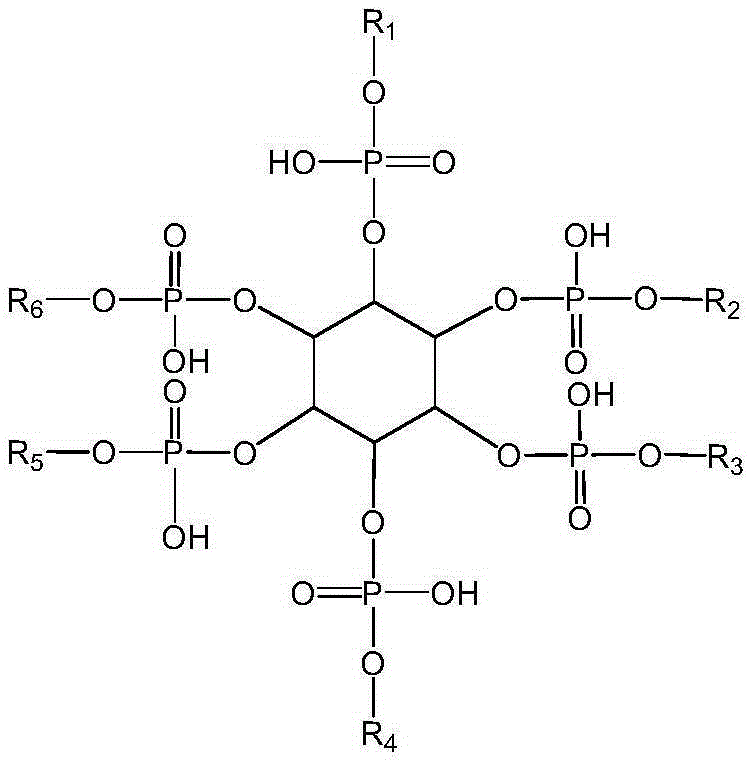

[0022] (1) Add 1 mol of natural phytic acid compound and 2 mol of γ-glycidoxytrimethoxysilane into 100 mL of acetone solution, stir and react at 70°C for 1 hour to obtain a flame retardant finishing solution, which contains 2 Phytic acid derivatives with active groups;

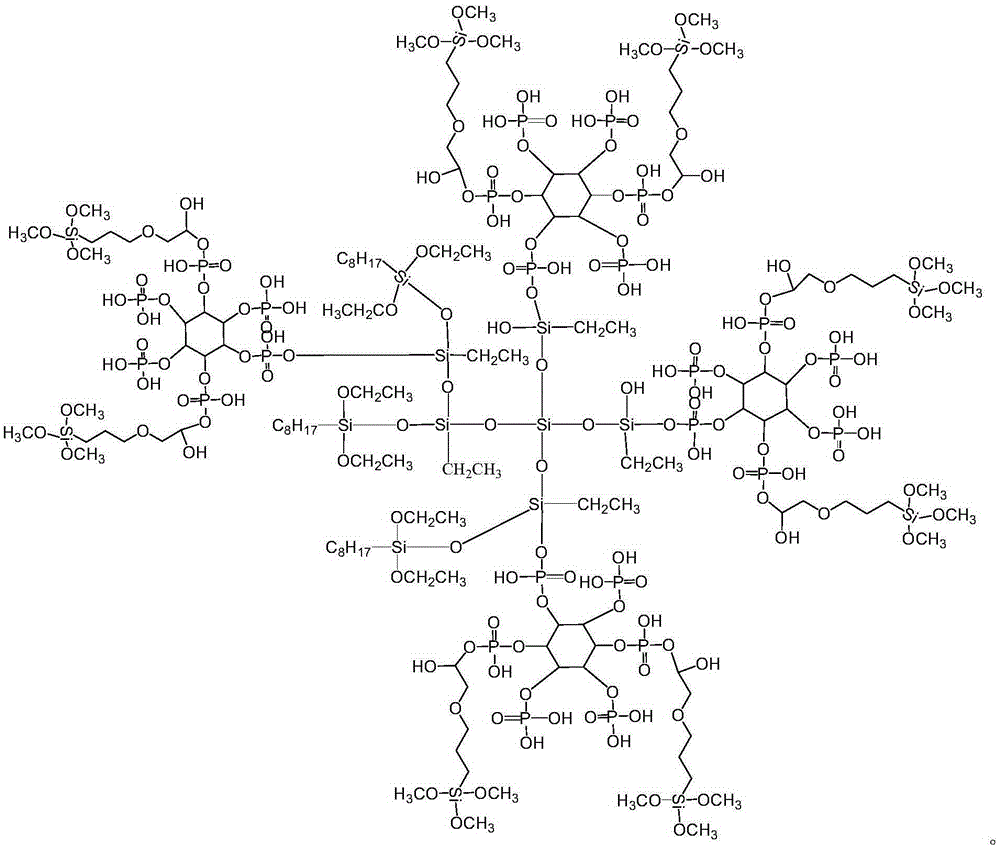

[0023] (2) Add 4 mol of silane coupling agent octyltriethoxysilane and 2 mol of ethyl orthosilicate to the above-mentioned flame retardant finishing solution, and stir and react continuously at 80°C for 5 hours to obtain a compound with dual functions of flame retardant and water repellency finishing fluid;

[0024] (3) The cotton fabric is soaked in the flame-retardant and water-repellent double-functional finishing solution obtained in step (2) for 10 minutes, then dipped and rolled twice, and the excess rate is 90%, and then the cotton fabric is dried at 80° C. for 5 minutes, and then dried at 170 Bake at ℃ for 3 min...

Embodiment 2

[0028] A kind of preparation method of flame-retardant cotton fabric, its process is as follows:

[0029] (1) Add 0.8 mol of natural phytic acid compound and 2.4 mol of γ-glycidoxytrimethoxysilane into 150 mL of methanol solution, stir and react continuously at 80°C for 0.5 h to obtain a flame retardant finishing solution, It is a phytic acid derivative containing 3 active groups;

[0030] (2) Add 3 mol of silane coupling agent hexadecyltrimethoxysilane and 1 mol of ethyl orthosilicate to the above-mentioned flame retardant finishing solution, and stir and react continuously at 70°C for 8 hours to obtain a flame retardant and water-repellent double Functional finishing fluid;

[0031] (3) The cotton fabric is soaked in the flame-retardant and water-repellent double-functional finishing solution obtained in step (2) for 10 minutes, then dipped and rolled twice, and the excess rate is 100%, and then the cotton fabric is dried at 60° C. for 8 minutes, and then dried at 160 Bake...

Embodiment 3

[0035] A kind of preparation method of flame-retardant cotton fabric, its process is as follows:

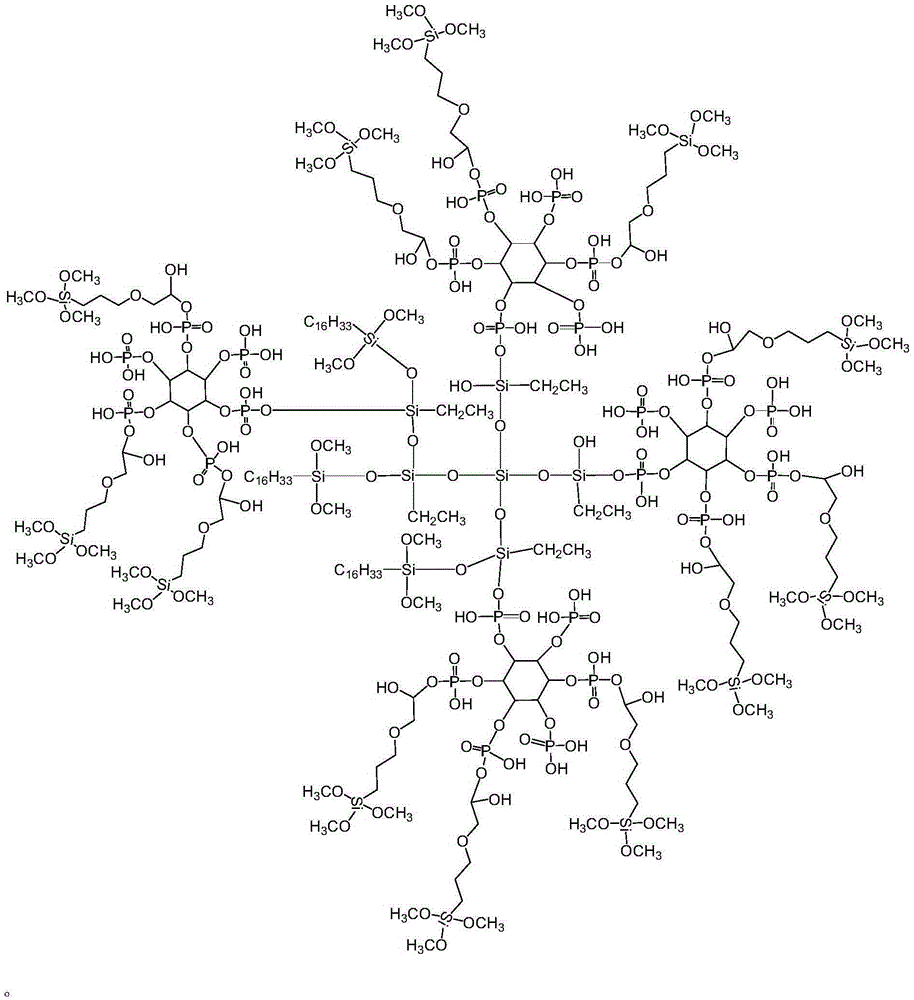

[0036] (1) Add 1.5mol of natural phytic acid compounds and 3mol of γ-glycidoxytrimethoxysilane into 200mL of ethanol solution, stir and react at 60°C for 2 hours to obtain a flame retardant finishing solution, which contains Phytic acid derivatives with 2 active groups;

[0037] (2) Add 5 mol of silane coupling agent tridecaperfluorohexyltriethoxysilane and 2 mol of tetraethoxyethyl orthosilicate to the above-mentioned flame retardant finishing solution, and continuously stir and react at 75°C for 4 hours to obtain a flame retardant and repellent Water dual-function finishing fluid;

[0038] (3) Immerse the cotton fabric in the flame-retardant and water-repellent double-functional finishing solution obtained in step (2) for 10 minutes, then dip and roll twice, and the excess rate is 110%, then dry the cotton fabric at 70°C for 4 minutes, and then dry it at 180 Bake at ℃ for 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com