Halogen-free phosphorus-containing flame retardant, preparation method thereof and bio-based halogen-free flame-retardant polylactic acid material prepared from halogen-free phosphorus-containing flame retardant

A technology of flame retardant and polylactic acid, which is applied in the manufacture of fire-retardant and flame-retardant filaments, chemical instruments and methods, compounds of elements of Group 5/15 of the periodic table, etc. , material performance reduction and other issues, to achieve the effect of high flame retardant efficiency, reduced mechanical properties, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0087] According to a preferred embodiment of the present invention, the amino alcohol compound is NH 2 C(CH 2 Oh) 2 (CH 2 ) n (CH 2 OH) or NH 2 (CH 2 CHOH) m CH 3 , wherein, n is an integer of 0-6, and m is an integer of 1-10.

[0088] According to a particularly preferred embodiment of the present invention, the aminoalcohol compound is aminobutanol (NH 2 C(CH 2 Oh) 3 ) or aminoisopropanol (NH 2 (CH 2 CHOH)CH 3 ), that is, n is 0 and m is 1.

[0089] According to another preferred embodiment of the present invention, the aminophenol compound is selected from 2-aminophenol is preferred 3-Aminophenol or 4-aminophenol That is, n is 0.

[0090] The second aspect of the present invention provides a halogen-free phosphorus-containing flame retardant, which is prepared from phytic acid and aminoalcohol or aminophenol compounds, preferably phytic acid and aminoalcohol compounds.

[0091] According to the present invention, the halogen-free phosphorus-containi...

Embodiment 1

[0162] Embodiment 1 Preparation of phytic acid-tromethamine halogen-free phosphorus-containing flame retardant

[0163] Dissolve 60 mmol of tromethamine in ethanol solvent, then slowly drop 5 mmol of phytic acid into the ethanol solution of tromethamine, monitor the pH value of the solution throughout the reaction until the solution is neutral, and end the reaction.

[0164] The precipitated product was collected and dried in a vacuum oven: first dried at 80° C. for 2 hours and then at 150° C. for 1 hour to obtain a phytic acid-tromethamine halogen-free phosphorus-containing flame retardant.

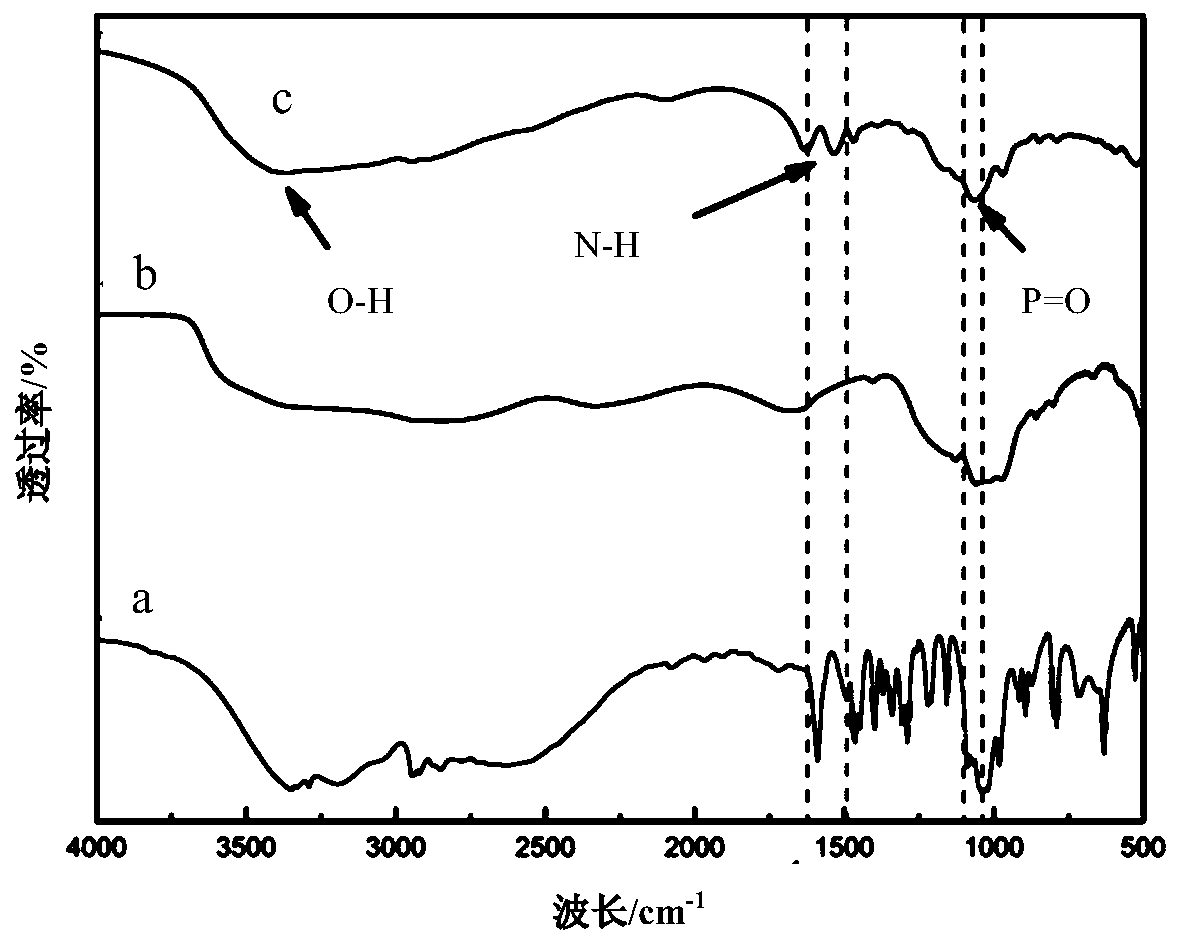

[0165] Infrared test (Nicolet iS50 Fourier transform infrared spectrometer) is carried out to gained phytic acid-tromethamine halogen-free phosphorus flame retardant, gained test result is as follows figure 1 shown.

[0166] figure 1 Among them, curve a is the infrared curve of tromethamine, curve b is the infrared curve of phytic acid, and curve c is the infrared curve of phytic acid-...

Embodiment 2

[0176] Embodiment 2 Preparation of phytic acid-aminoisopropanol halogen-free phosphorus-containing flame retardant

[0177] Dissolve 60mmol of aminoisopropanol in ethanol solvent, then slowly drop 5mmol of phytic acid into the ethanol solution of aminoisopropanol, monitor the pH value of the solution throughout the reaction until the solution is neutral, and end the reaction.

[0178] The precipitated product was collected and dried in a vacuum oven: dried at 80° C. for 2 hours, and dried at 150° C. for 1 hour to obtain a phytic acid-aminoisopropanol halogen-free phosphorus-containing flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com