Transparent lining cloth and its making method

A manufacturing method and interlining technology, which is applied to textiles, papermaking, clothing, clothing, etc., to achieve good resilience and save dyeing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

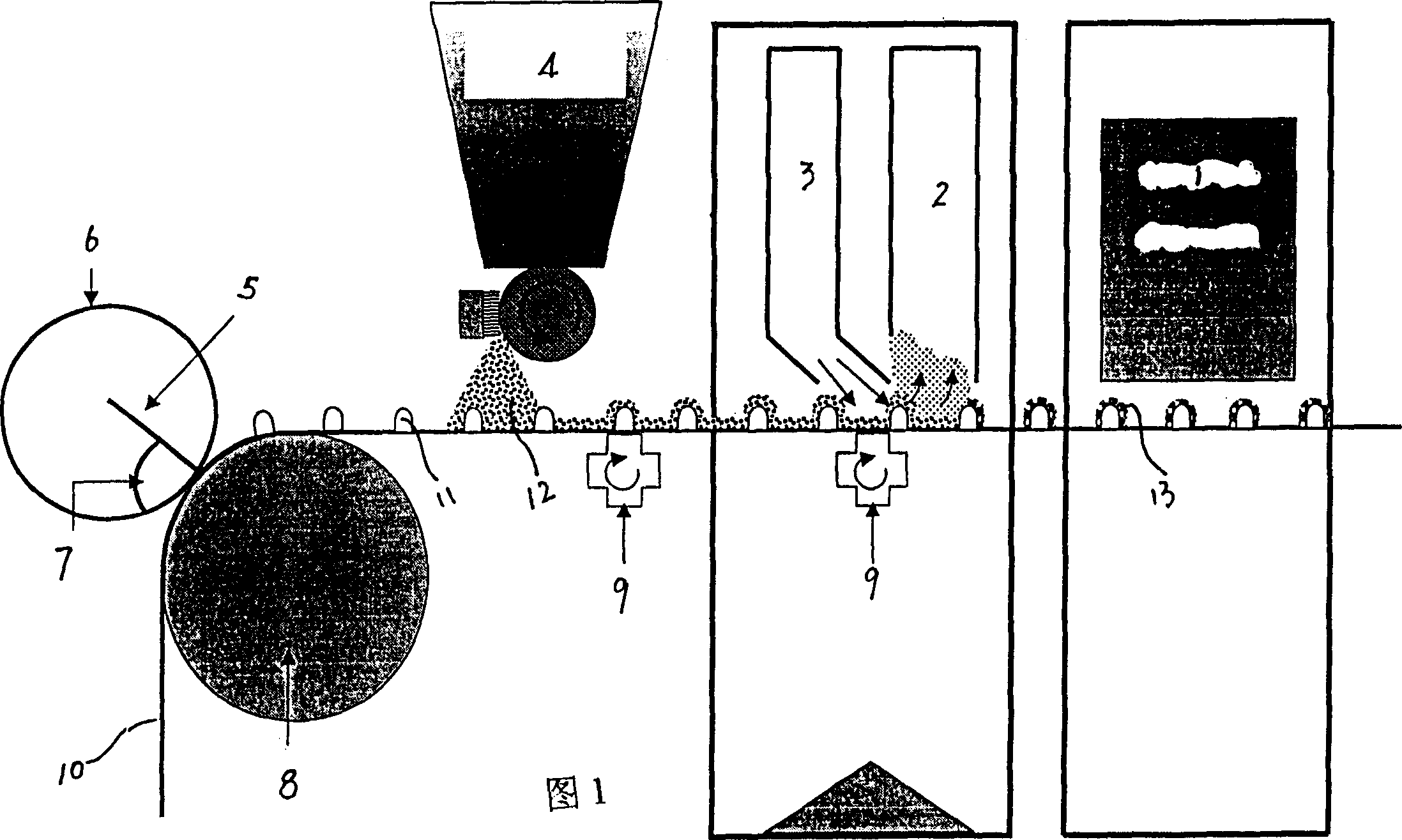

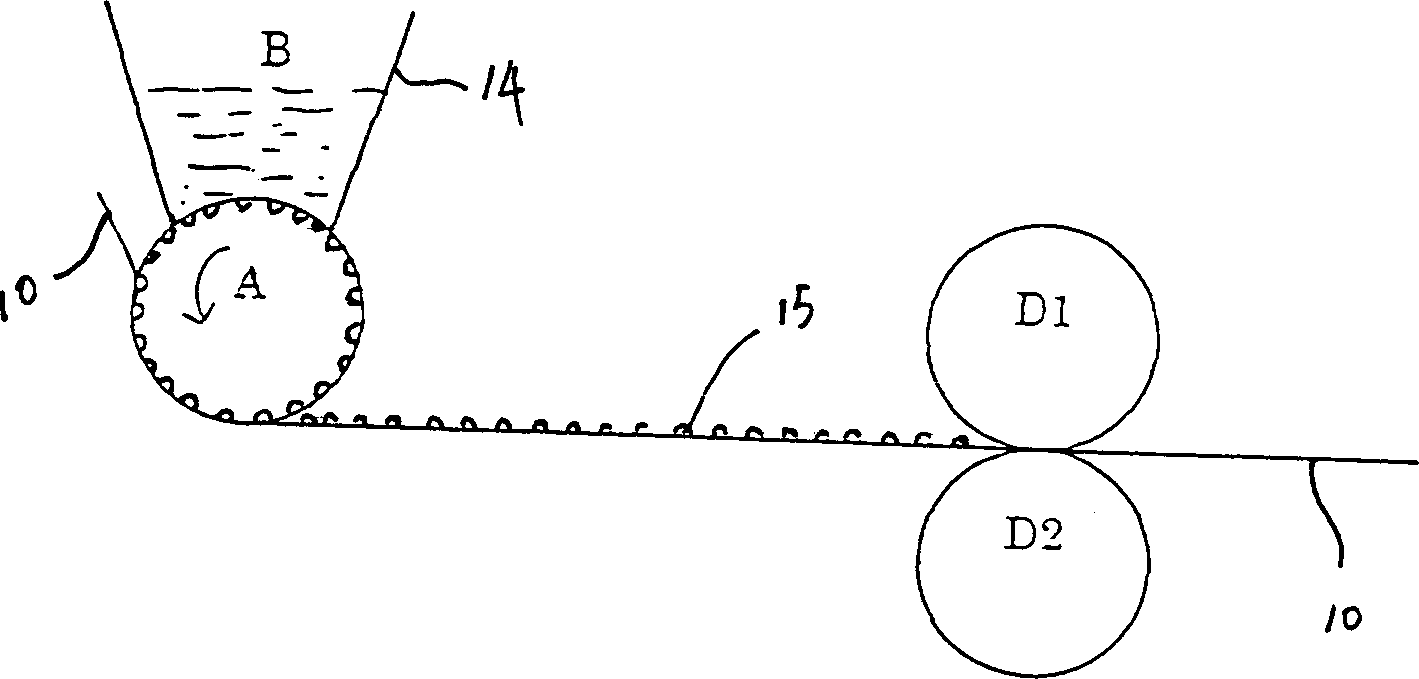

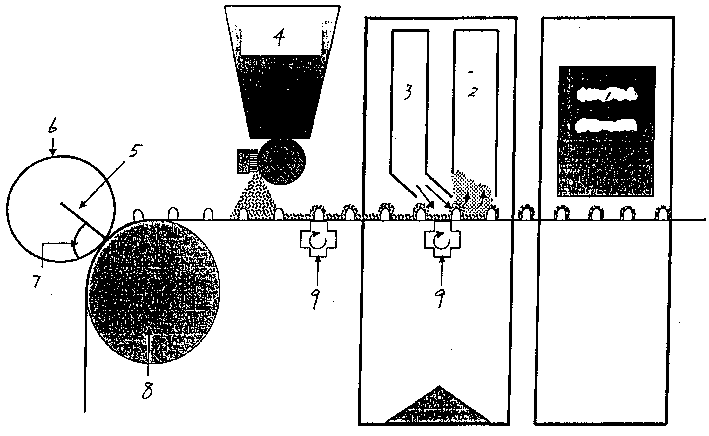

Method used

Image

Examples

Embodiment 1

[0049] a. Scouring. Add water and additives to the required amount in the liquid tank of the refining machine to make a scouring liquid. After the temperature rises to 50°C, put the base fabric into the liquid tank to make the water and the base cloth circulate in the liquid tank together. Rotating, the amount of additives added is 0.1 g / L of metal ion chelating agent, 1.0 g / L of desizing agent, 1.0 g / L of softener in bath, and 1.0 g / L of sodium carbonate. After 15 minutes, drain the refining solution, add cold water to wash and take it out. Open the scoured base cloth with an open-width machine, and then dry it in a dryer at a drying temperature of 80°C;

[0050] b. Finishing: add the finishing solution prepared by water and additives into the liquid tank of the softening machine, make the base cloth pad and roll the finishing solution, and then enter the drying and setting machine in the finishing machine for drying and setting, which will help The amount of agent added is ...

Embodiment 2

[0053] a. Scouring, add water and additives to the required amount in the liquid tank of the refining machine to prepare a scouring liquid. After the temperature rises to 70°C, put the base cloth into the liquid tank to make the water and the base cloth circulate in the liquid tank together. Rotate, the amount of additives added is 0.4 g / L of metal ion chelating agent, 2.0 g / L of desizing agent, 2.0 g / L of softener in the bath, 3.0 g / L of sodium carbonate, and then heat up to the scouring temperature of 100°C, and scouring After 25 minutes, drain the refining solution, add cold water to wash and take it out. Open the scoured base cloth with an open-width machine, and then dry it through a dryer at a drying temperature of 120°C;

[0054] b. Finishing: add the finishing solution prepared by water and additives into the liquid tank of the softening machine, make the base cloth pad and roll the finishing solution, and then enter the drying and setting machine in the finishing mach...

Embodiment 3

[0057] a. Scouring, add water to the required amount and additives in the liquid tank of the refining machine to prepare a scouring liquid. After the temperature rises to 60°C, put the base cloth into the liquid tank to make the water and the base cloth circulate in the liquid tank together Rotate, the amount of additives added is 0.25 g / L of metal ion chelating agent, 1.5 g / L of desizing agent, 1.5 g / L of softener in the bath, 2.0 g / L of sodium carbonate, and then heat up to the scouring temperature of 90 ° C, scouring After 20 minutes, drain the refining solution, add cold water to wash and take it out. Open the scoured base fabric with an open-width machine, and then dry it through a dryer at a drying temperature of 90°C;

[0058] b. Finishing: add the finishing solution prepared by water and additives into the liquid tank of the softening machine, make the base cloth pad and roll the finishing solution, and then enter the drying and setting machine in the finishing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com