Disperse blue dye composition, disperse dye, preparation method and application

A technology of dye composition and disperse dyes, which is applied in dyeing methods, organic dyes, textiles and papermaking, etc., and can solve problems such as poor dyeing depth, high dyeing cost, and heavy pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

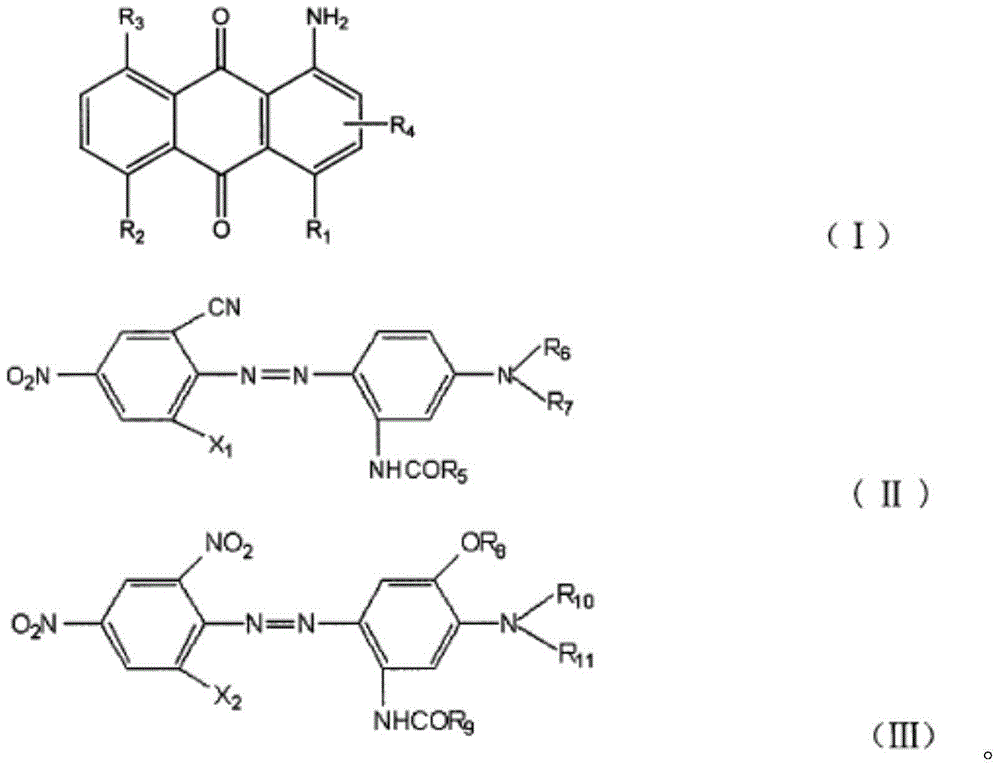

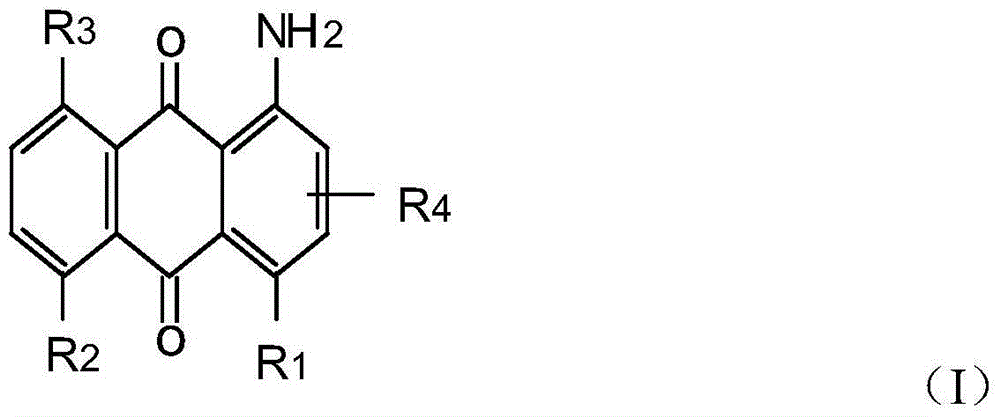

Method used

Image

Examples

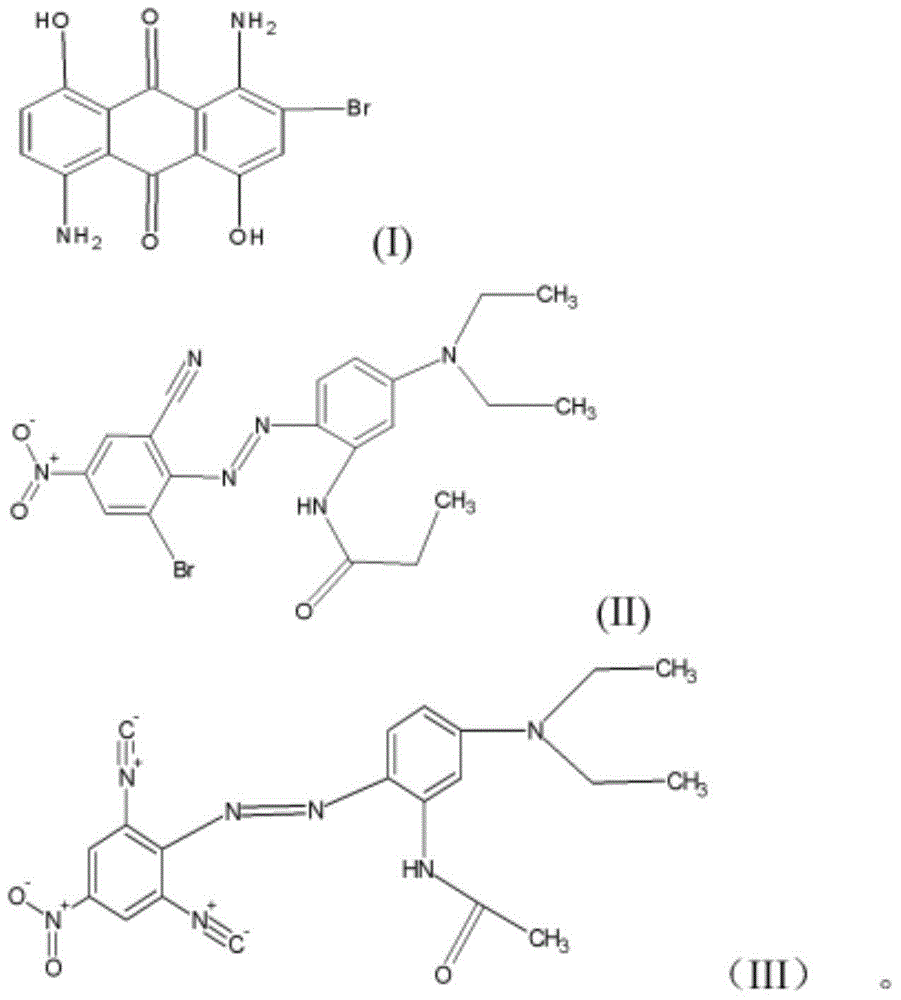

Embodiment 1

[0111] Add 59 grams of formula (Ia) component A, 36 grams of formula (II) component B, 5 grams of formula (IIIa) component C and 200 grams of methyl naphthalenesulfonic acid formaldehyde condensate (dispersant MF), add water After mixing, use a sand mill to grind and disperse to make a slurry, or further spray dry to make a blue disperse dye.

[0112]

Embodiment 2

[0128] Add 56 grams of formula (Ia) component A, 34 grams of formula (II) component B, 4.8 grams of formula (IIIa) component C, 5.2 grams of formula (Va) component E and 200 grams of lignin 85A, add water After mixing, use a sand mill to grind and disperse to form a slurry, or further spray dry to form a blue disperse dye.

[0129]

Embodiment 3-15

[0142] According to the method of Example 1 or Example 2, according to the raw materials provided in Table 3, add water and mix them, then grind and disperse them with a sand mill to prepare a slurry, or further perform spray drying to prepare a blue disperse dye.

[0143] Table 3 Unit: Gram

[0144]

[0145]

[0146]

[0147] Note: The water weight in Table 3 is the water content of the final product.

[0148] Perform performance tests on the finished dye products of the foregoing Examples 3-15.

[0149] The specific test method is as follows:

[0150] According to the similar method of GB / T2394-2006, respectively weigh 0.5 g of the finished dye products of Examples 3-15 into 250 ml of water to prepare a disperse dye suspension. Take 20ml of disperse dye suspension and mix with 80ml of water, adjust the dye bath pH to 5 with acetic acid, then heat to 60℃, and put 2g of polyester fiber into high temperature and high pressure dyeing, heat up to 130℃ in 35 minutes, keep warm for 45 Minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com