Ruby azo dye as well as preparation method and application thereof

A ruby azo and dye technology, applied in the field of dyes, can solve the problems of poor washing fastness, affecting the dyeing fastness of dyes to fabrics, etc., and achieve the effects of low cost, excellent washing fastness and high dyeing strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

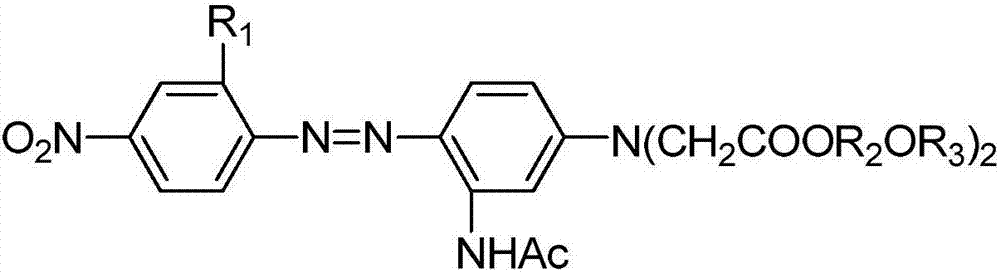

[0034] A kind of ruby azo dye of the present embodiment, structural formula is as follows:

[0035]

[0036] where R 1 means CN;

[0037] R 2 represents methylene;

[0038] R 3 Indicates ethyl.

[0039] The preparation method of this ruby azo dye is as follows:

[0040] (1) Take chloroacetic acid, HO(CH 2 ) n O(CH 2 ) m CH 3 , reflux dehydration in a toluene system at 100-150 degrees Celsius for esterification to obtain ester reactants;

[0041] Among them, the possible value of n is 1, and the possible value of m is 1;

[0042] (2) Take m-aminoacetanilide, and react with ester reactants under the action of sodium carbonate at 100-150 degrees Celsius. After the reaction is completed, excess ester reactants are evaporated, and water is added to remove the oil layer, and ice is added to the oil layer. Acetic acid is dissolved to obtain the coupling component;

[0043] (3) Add water in the diazo kettle, and slowly add sulfuric acid at a temperature lower than ...

Embodiment 2

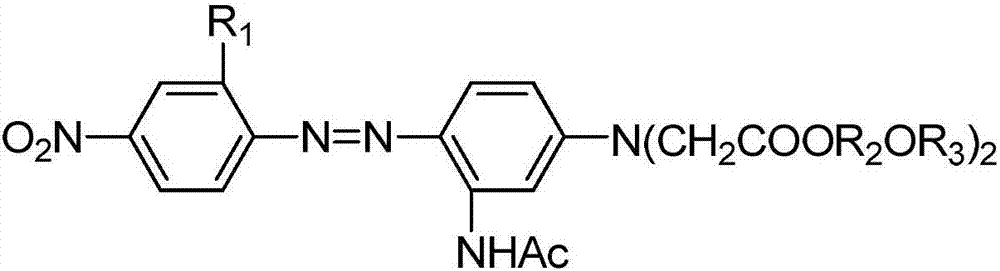

[0049] A kind of ruby azo dye of the present embodiment, structural formula is as follows:

[0050]

[0051] where R 1 means Cl;

[0052] R 2 represents ethylene;

[0053] R 3 Indicates methyl.

[0054] The preparation method of the ruby azo dye refers to Example 1. In this example, the value of n is 2, and the value of m is 0.

Embodiment 3

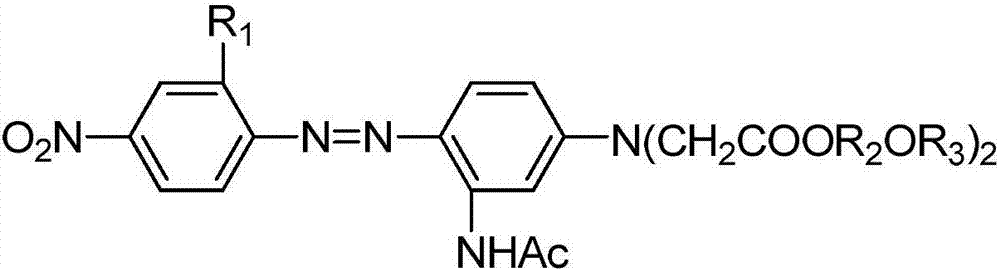

[0056] A kind of ruby azo dye of the present embodiment, structural formula is as follows:

[0057]

[0058] where R 1 means CN;

[0059] R 2 represents ethylene;

[0060] R 3 Indicates butyl.

[0061] The preparation method of the ruby azo dye refers to Example 1. In this example, the value of n is 2, and the value of m is 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com