Method for dyeing aramid fiber without carrier

A dyeing method and carrier-free technology, which is applied in the field of textile printing and dyeing, can solve the problems of increased yarn or fabric cost, increased dyeing cost, and inability to recycle, and achieve the effects of reducing dyeing cost, ideal dyeing effect, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

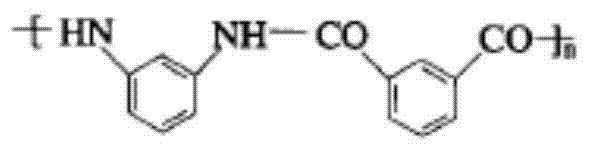

[0027]Take the dyeing of 1313 fiber as an example.

[0028] A) To prepare a dyeing bath, first pour water into the dyeing container, control the bath ratio to 1:50, then add disperse dye, disperse red 3B, into the dyeing container, the amount of disperse red 3B is 15% (o.w.f) and used as a leveling agent Add O (alkyl polyoxyethylene ether) 10g / L to Pingping, and then use acetic acid as a buffer to adjust the pH of the dye bath to 6;

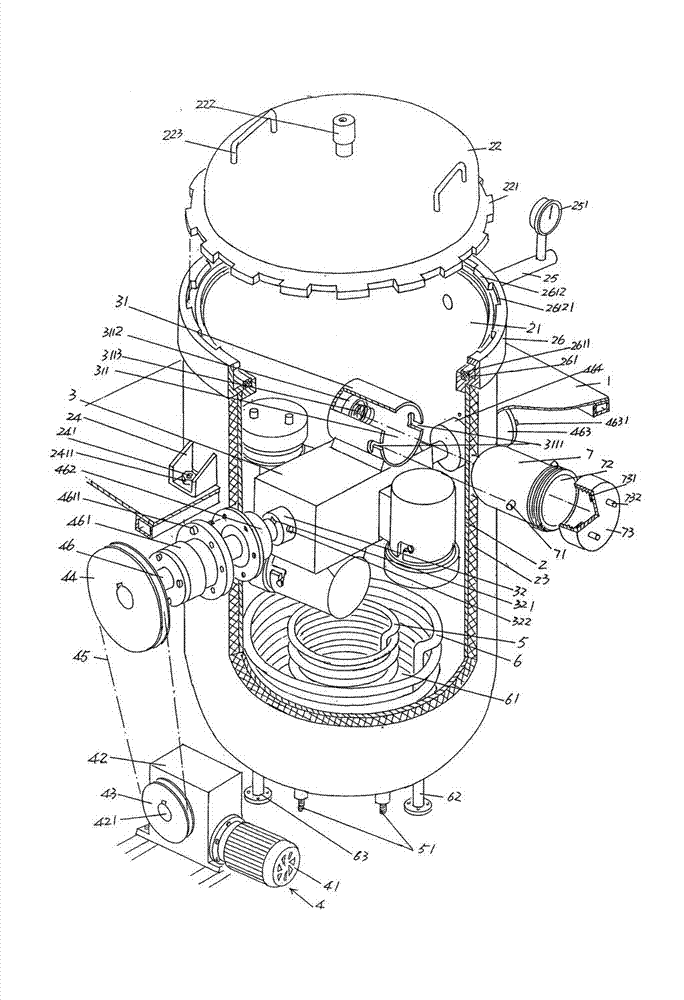

[0029] B) Dyeing, first soak the aramid 1313 fiber in clean water, then squeeze the water dry and put it into the dyeing bath, then put the dyeing container into the dyeing machine for dyeing, the dyeing temperature of the dyeing machine is controlled at 150°C and the dyeing time The dyeing pressure is controlled at 90min, and the dyeing pressure is controlled at 0.43MPa. After leaving the dyeing machine, the dyed aramid 1313 fiber is taken out of the dyeing container, and then washed, reduced and washed with water in sequence according to the co...

Embodiment 2

[0044] Take the dyeing of aramid 1313 yarn as an example.

[0045]Only change the bath ratio in step A) to 1:10, change the dye to disperse blue 2BLN, and change the dosage to 0.02% (o.w.f), change the dosage of leveling agent O to 20g / L, and change the buffer Use citric acid instead, and change the pH value to 5.6; only change the dyeing temperature, dyeing time, and dyeing pressure in step B) to 220°C, 30min, and 2.3MPa, respectively, to obtain blue aramid 1313 yarn, and the rest are Same as the description of embodiment 1.

Embodiment 3

[0047] Take the dyeing of aramid 1313 fabric as an example.

[0048] Only change the bath ratio in step A) to 1:35, change the dye to cationic red 2GL, and change the dosage of cationic red 2GL to 10% (o.w.f), change the dosage of Pingpingjiao to 5g / L, change Change the buffer to formic acid and change the pH value to 4; only change the dyeing temperature, dyeing time and dyeing pressure in step B) to 170°C, 45min and 0.9MPa respectively to obtain a red aramid 1313 fabric, and the rest are the same Description of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com