Activated dye low-alkaline dyeing method for black regenerated cellulose fiber cheese

A technology of regenerated cellulose and reactive dyes, applied in the field of printing and dyeing, which can solve the problems that regenerated cellulose fibers cannot reduce the dyeing temperature and the amount of dyeing soda ash, so as to improve equipment efficiency, reduce dyeing temperature, and improve color fastness to washing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

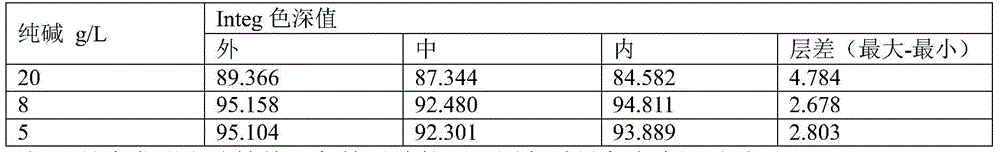

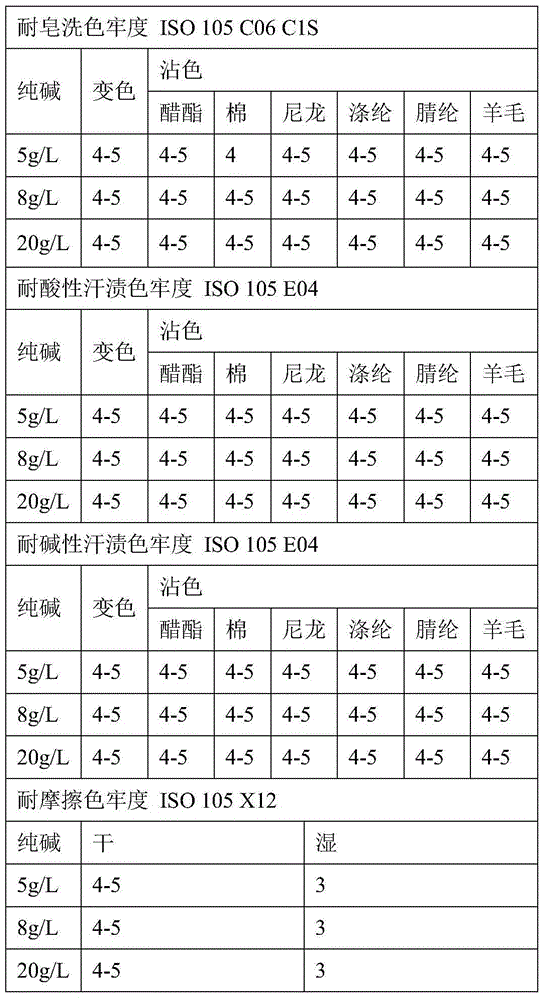

Embodiment 1

[0026] A kind of reactive dye low-alkali dyeing method of black regenerated cellulose fiber cheese, specifically comprises the following steps:

[0027] (1) Pretreatment: add refining agent and soda ash to water, stir until they are completely dissolved, put them into the main vat with regenerated cellulose fiber cheese, add the water in the main vat to the predetermined water level, cover it, and heat up to 78°C, under continuous circulation for 25 minutes (forward 4 reverse 3 cycles), then drain the water and wait for dyeing; the concentration of refining agent in the main vat is 0.5g / L, and the concentration of soda ash is 2g / L;

[0028] The refining agent is a mixed aqueous solution of fatty alcohol ethoxylate and butyl diglycol, the mass concentration of fatty alcohol ethoxylate is 25 wt%, and the mass concentration of butyl diglycol is 20 wt%.

[0029] (2) Dyeing: Add 6 times the weight of regenerated cellulose fiber package yarn and 80g / L aqueous solution of sodium anhy...

Embodiment 2

[0037] A kind of reactive dye low-alkali dyeing method of black regenerated cellulose fiber cheese, specifically comprises the following steps:

[0038] (1) Pretreatment: add refining agent and soda ash to water, stir until they are completely dissolved, put them into the main vat with regenerated cellulose fiber cheese, add the water in the main vat to the predetermined water level, cover it, and heat up to 82°C, under continuous circulation for 20 minutes (forward 4 reverse 3 cycles), then drain the water and wait for dyeing; the concentration of refining agent in the main vat is 2g / L, and the concentration of soda ash is 1g / L;

[0039] The refining agent is a mixed aqueous solution of fatty alcohol ethoxylate and butyl diglycol, the mass concentration of fatty alcohol ethoxylate is 25 wt%, and the mass concentration of butyl diglycol is 20 wt%.

[0040] (2) Dyeing: Add 8 times the weight of regenerated cellulose fiber package yarn and an aqueous solution of 50 g / L sodium an...

Embodiment 3

[0048] A kind of reactive dye low-alkali dyeing method of black regenerated cellulose fiber cheese, specifically comprises the following steps:

[0049] (1) Pretreatment: add refining agent and soda ash to water, stir until they are completely dissolved, put them into the main vat with regenerated cellulose fiber cheese, add the water in the main vat to the predetermined water level, cover it, and heat up to 80°C, under continuous circulation for 21 minutes (forward 4 reverse 3 cycles), then drain the water and wait for dyeing; the concentration of refining agent in the main vat is 1g / L, and the concentration of soda ash is 1g / L;

[0050] The refining agent is a mixed aqueous solution of fatty alcohol ethoxylate and butyl diglycol, the mass concentration of fatty alcohol ethoxylate is 25 wt%, and the mass concentration of butyl diglycol is 20 wt%.

[0051] (2) Dyeing: Add 7 times the weight of regenerated cellulose fiber package yarn and 60g / L aqueous solution of sodium sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com