Disperse blue dye composition, disperse dye, and preparation method and application of disperse dye

A technology of dye composition and disperse blue, which is applied in the fields of dyeing, organic dyes, textiles and papermaking, etc. It can solve problems such as inability to meet customer requirements, and achieve the effects of saving dye usage, clear outline, and good fastness to saliva

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

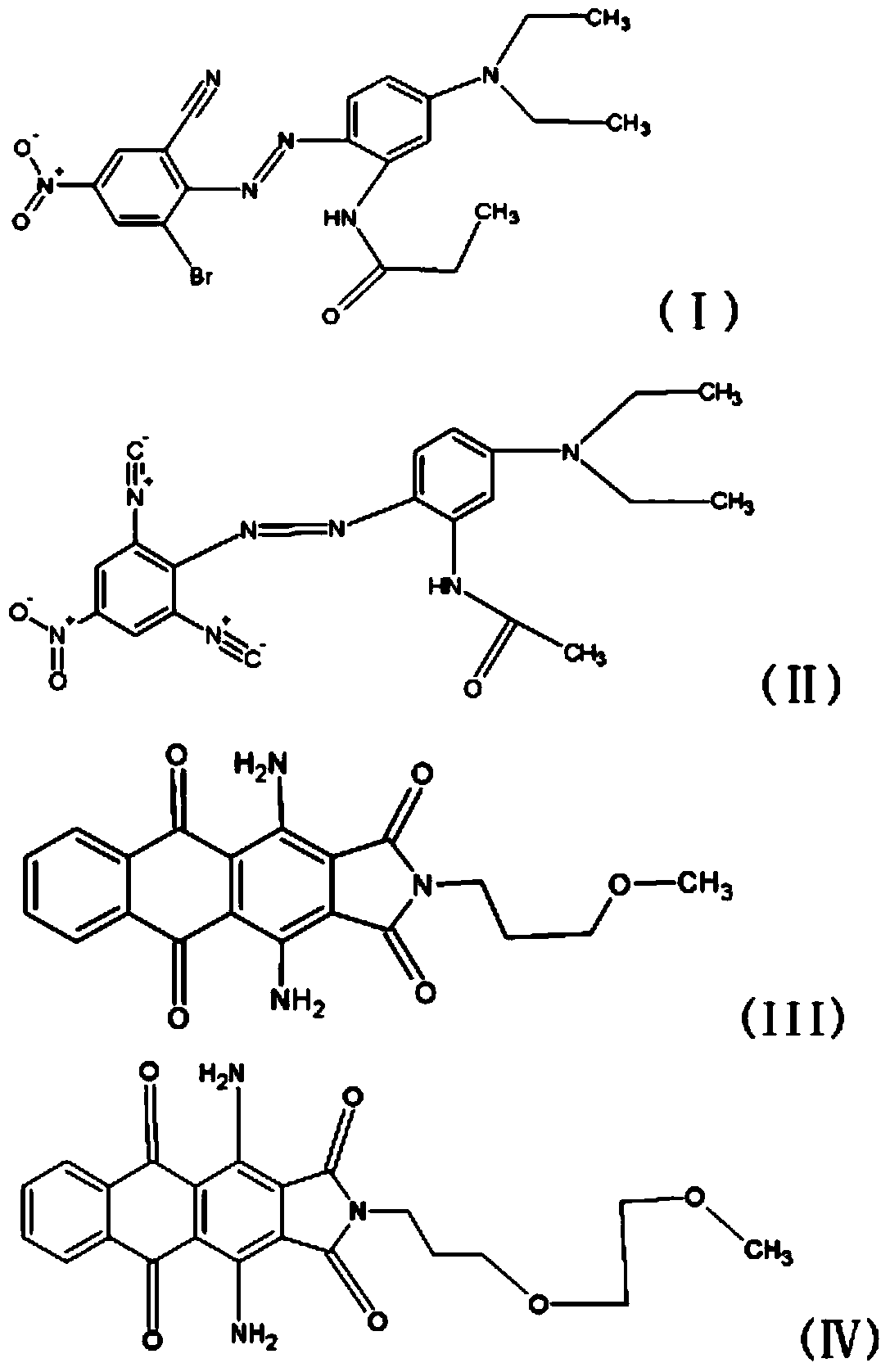

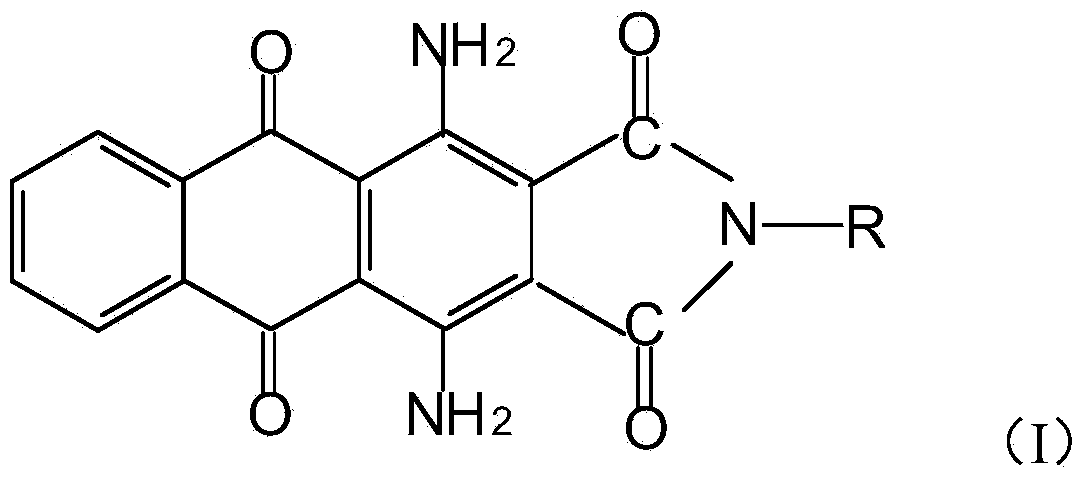

[0026] The preparation method of structural formula (I-1): 1,4-diaminoanthraquinone is chlorinated, sulfonated, cyanided, dehydrated and ring-closed, and then condensed with methylamine.

[0027] The preparation method of structural formula (I-2): 1,4-diaminoanthraquinone is chlorinated, sulfonated, cyanided, dehydrated and ring-closed, and then condensed with ethylamine.

[0028] The preparation method of structural formula (I-3): 1,4-diaminoanthraquinone is chlorinated, sulfonated, cyanided, dehydrated and ring-closed, and then condensed with propylamine.

[0029] The preparation method of structural formula (I-4): 1,4-diaminoanthraquinone is chlorinated, sulfonated, cyanided, dehydrated and ring-closed, and then condensed with isopropylamine.

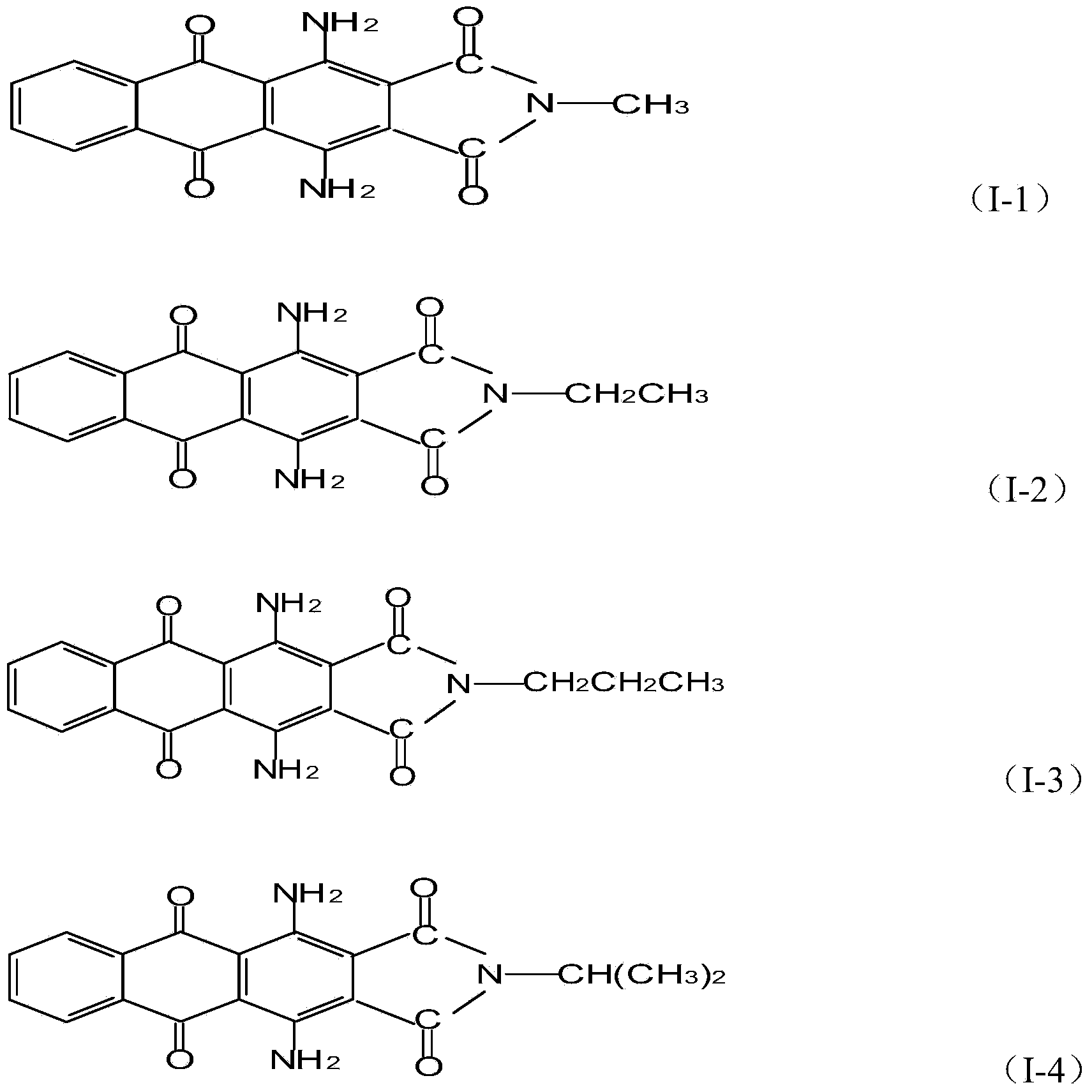

[0030] Structural formula (I-5) is C.I. Disperse Blue 60.

[0031] The preparation method of structural formula (I-6): chlorination, sulfonation, cyanation, dehydration and ring closure of 1,4-diaminoanthraquinone, and then condensa...

Embodiment 1-9

[0037] According to the components and contents shown in Table 1, the prepared dye composition, auxiliary agent and water were mixed, ground, and spray-dried to obtain a composite disperse dye.

[0038] Table 1 (unit: gram)

[0039]

Embodiment 10-20

[0048] According to the components and contents shown in Table 3, the prepared dye composition and auxiliary agent were mixed with water, ground, and spray-dried to obtain a composite disperse dye.

[0049] Table 3 (unit: gram)

[0050]

[0051]

[0052] Comparative sample 2: replace the compound in Example 1 with the components in the patent No. CN201110457474.5, and the auxiliary agent remains unchanged.

[0053]Take by weighing the disperse dyes prepared in Example 10-20 and comparative sample 1 and comparative sample 2, configure the disperse dyes of 50g / l, 100g / l, 150g / l, all the other add printing paste and water, beating, printing , drying, color fixing, washing, and setting to make printed textiles. According to the standards of GB / T2397-2012, GB / T5718-1997, and GB / T18886-2002, the lifting force, sublimation fastness, and saliva resistance are measured. The test results are shown in Table 4:

[0054] Table 4 (unit: level)

[0055] Example

[0056] As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com