A preparation method of spray-free aesthetic resin for improving appearance

An aesthetic resin, spray-free technology, applied in the field of the preparation of spray-free aesthetic resin, can solve the problem that the affinity of toner and substrate is difficult to improve, so as to improve processability, improve affinity, reduce welding lines and The effect of flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of a spray-free aesthetic resin for improving appearance, the method comprising the following steps:

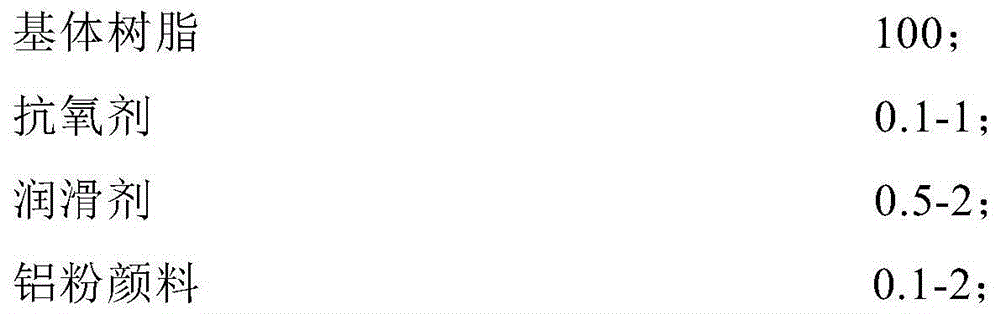

[0025] (1) Prepare materials according to the following components and parts by weight:

[0026] Base resin 100;

[0027] Antioxidant 0.2;

[0028] lubricant 1;

[0029] Aluminum powder pigment 0.5;

[0030] Among them, the matrix resin is DuPont's PET530, the antioxidant is Irganox B900, the lubricant is ethylene-acrylic acid copolymer, the shape of the aluminum powder is silver dollar, and the particle size is 20 μm to 40 μm;

[0031] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them, and after mixing evenly, send them into the twin-screw extruder through a metering device. Under the conveying, shearing and kneading process, the material is melted and compounded, and then extruded through the die, drawn, cooled, and pelletized to obtain the spray-free aesthetic resin with improved app...

Embodiment 2

[0033] A preparation method of a spray-free aesthetic resin for improving appearance, the method comprising the following steps:

[0034] (1) Prepare materials according to the following components and parts by weight:

[0035] Base resin 100;

[0036] Antioxidant 0.2;

[0037] lubricant 1;

[0038] Aluminum powder pigment 0.5;

[0039] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them, and after mixing evenly, send them into the twin-screw extruder through a metering device. Under the conveying, shearing and kneading process, the materials are melted and compounded, and then extruded through a die equipped with an ultrasonic device, drawn, cooled, and pelletized to obtain a spray-free aesthetic resin with improved appearance.

[0040] Among them, the matrix resin is PET530 of DuPont;

[0041] The antioxidant is Irganox B900;

[0042] The lubricant is ethylene-acrylic acid copolymer;

[0043] The shape of the al...

Embodiment 3

[0046] A preparation method of a spray-free aesthetic resin for improving appearance, the method comprising the following steps:

[0047] (1) Prepare materials according to the following components and parts by weight:

[0048] Base resin 100;

[0049] Antioxidant 0.2;

[0050] lubricant 1;

[0051] Aluminum powder pigment 0.5;

[0052] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them, and after mixing evenly, send them into the twin-screw extruder through a metering device. Under the conveying, shearing and kneading process, the materials are melted and compounded, and then extruded through a die equipped with an ultrasonic device, drawn, cooled, and pelletized to obtain a spray-free aesthetic resin with improved appearance.

[0053] Among them, the matrix resin is PET530 of DuPont;

[0054] The antioxidant is Irganox B900;

[0055] The lubricant is ethylene-acrylic acid copolymer;

[0056] The shape of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com