Spraying-free pearlescent ABS material and preparation method thereof

An ABS material and spray-free technology, which is applied in the field of spray-free pearlescent ABS material and its preparation, can solve the problems of flow marks and fluidity differences of parts, and achieve the effects of easy processing and molding, high production efficiency and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

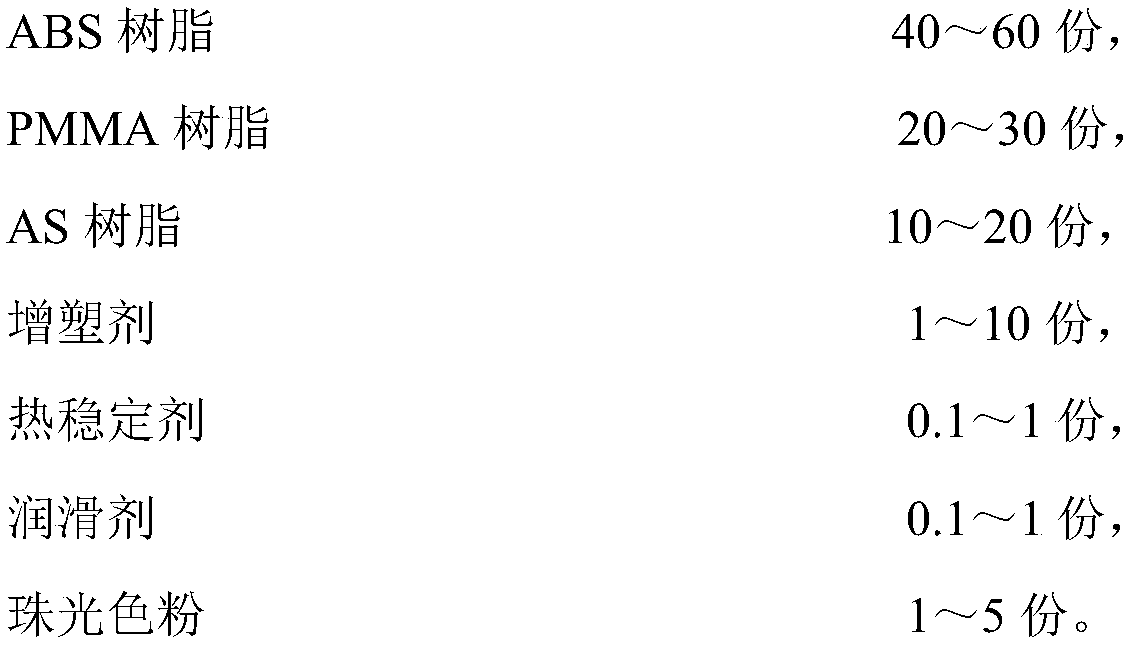

Method used

Image

Examples

Embodiment 1

[0044] (1) Put 60 parts of ABS HI-121H, 20 parts of PMMA-CM-205, 0.3 parts of light and heat stabilizer (antioxidant 1076:antioxidant 168=1:2, mass ratio) and 0.1 part of lubricant EBS through Stir at high speed to mix evenly;

[0045] (2) Mix 20 parts of AS SP23, 1 part of TPP, and 5 parts of pearlescent toner with high-speed stirring;

[0046] (3) The mixture in the step (1) is sent into a twin-screw extruder, and the mixture in the step (2) is sent into a side feeding inlet, extruded and granulated;

[0047] In the step (3), the screw temperature in the first zone of the twin-screw extruder is 200°C; the screw temperature in the second zone to the fourth zone is 240-250°C, and the screw temperature from the fifth zone to the machine head is 230-240°C; the screw speed 300r / min.

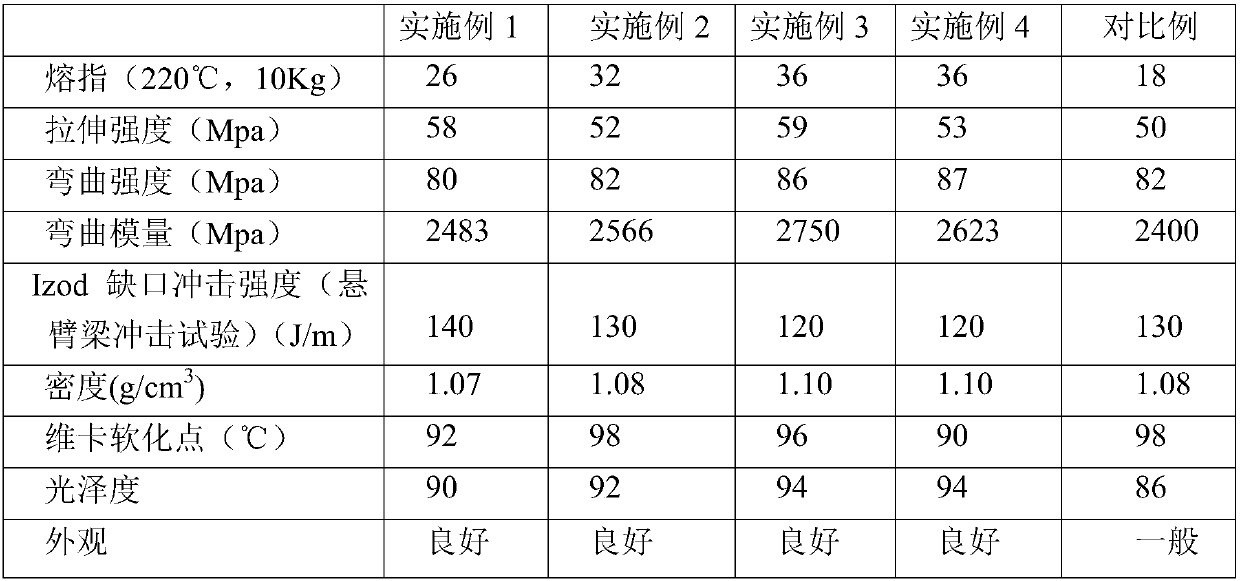

[0048] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 2

[0050] (1) Mix 60 parts of ABS HI-121H, 25 parts of PMMA-CM-205, 1 part of light and heat stabilizer DLTP and 0.3 part of lubricant liquid paraffin through high-speed stirring;

[0051] (2) Mix 10 parts of AS SP23, 5 parts of PX-220, and 3 parts of pearlescent toner at high speed and mix well.

[0052] (3) The mixture in the step (1) is sent into a twin-screw extruder, and the mixture in the step (2) is sent into a side feeding inlet, extruded and granulated;

[0053] In the step (3), the screw temperature in the first zone of the twin-screw extruder is 200°C; the screw temperature in the second zone to the fourth zone is 240-250°C, and the screw temperature from the fifth zone to the machine head is 230-240°C; the screw speed 400r / min.

[0054] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

Embodiment 3

[0056](1) Mix 40 parts of ABS HI-121H, 30 parts of PMMA-CM-205, 0.3 part of light and heat stabilizer DLTP and 0.5 part of lubricant silicone oil by high-speed stirring;

[0057] (2) Mix 20 parts of AS SP23, 10 parts of PX-220, and 5 parts of pearlescent toner at high speed and mix evenly.

[0058] (3) The mixture in the step (1) is sent into a twin-screw extruder, and the mixture in the step (2) is sent into a side feeding inlet, extruded and granulated;

[0059] In the step (3), the screw temperature in the first zone of the twin-screw extruder is 200°C; the screw temperature in the second zone to the fourth zone is 240-250°C, and the screw temperature from the fifth zone to the machine head is 230-240°C; the screw speed 400r / min.

[0060] The prepared compound was injection-molded into a standard sample bar for testing according to the standard size, and the performance test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com