Air conditioner panel assembly and air conditioner

A technology of panel components and air conditioners, which is applied in the direction of heating and ventilation hoods/covers, etc., can solve problems such as unsatisfactory metallic luster effects, increased production costs, flow marks, etc., to improve metallic luster effects, simplify production processes, and improve smoothness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

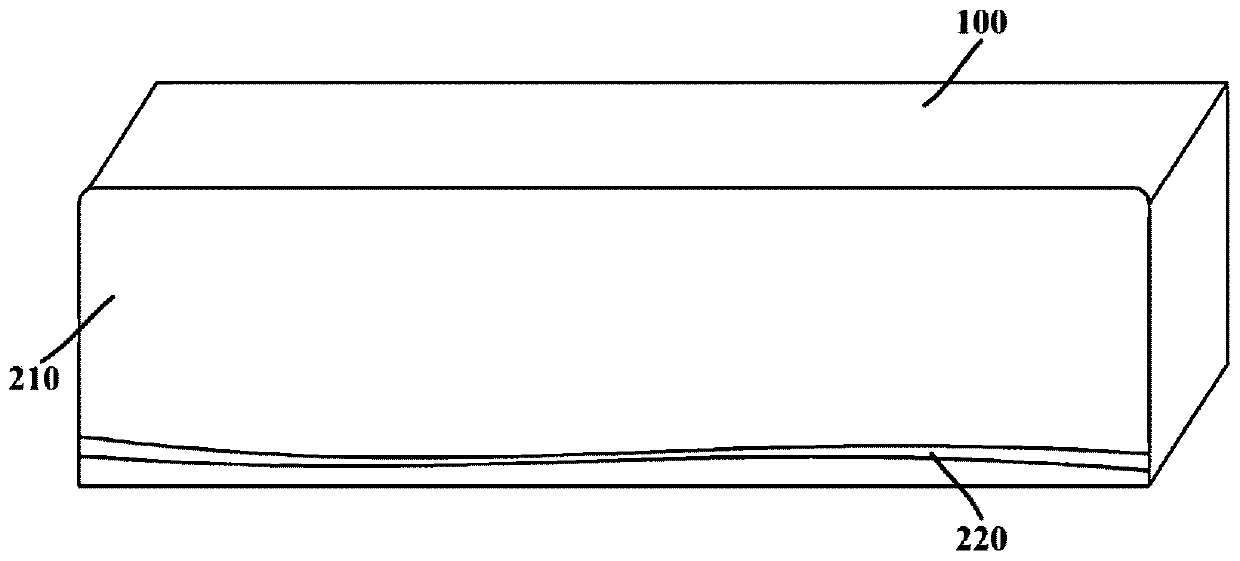

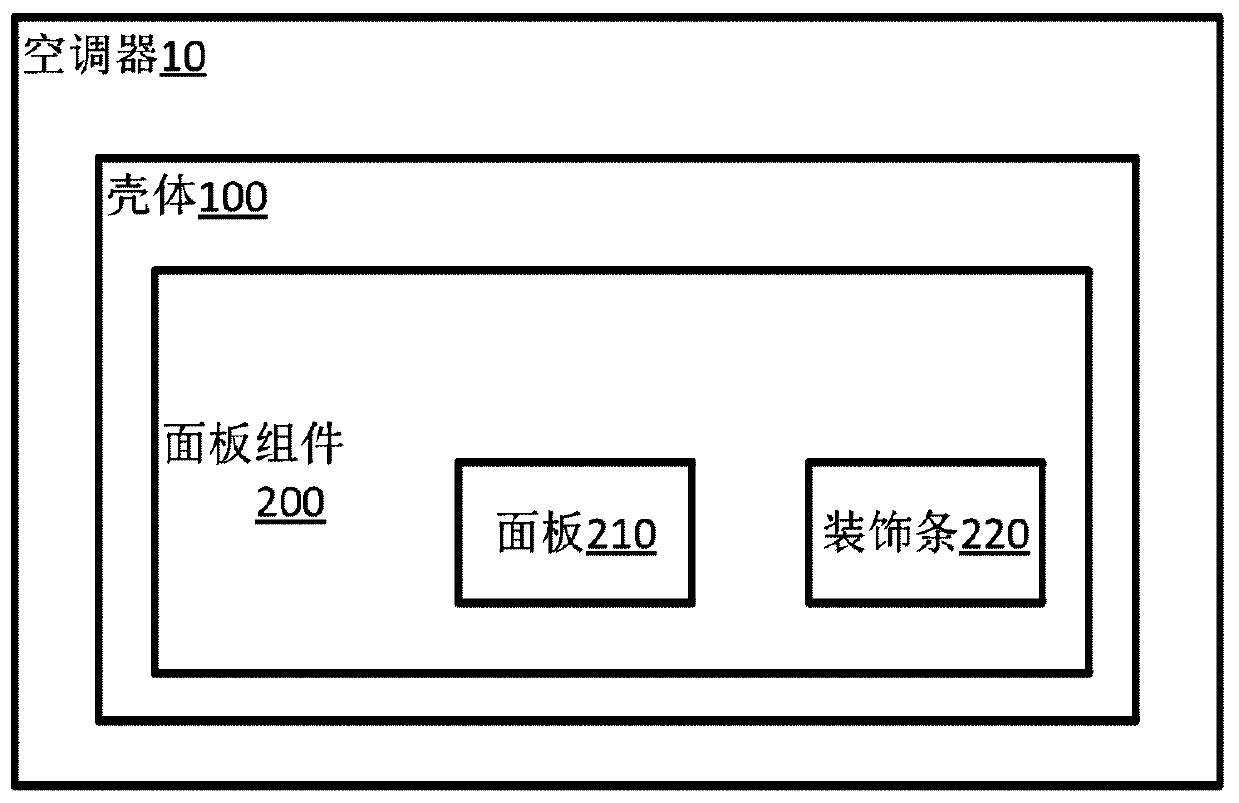

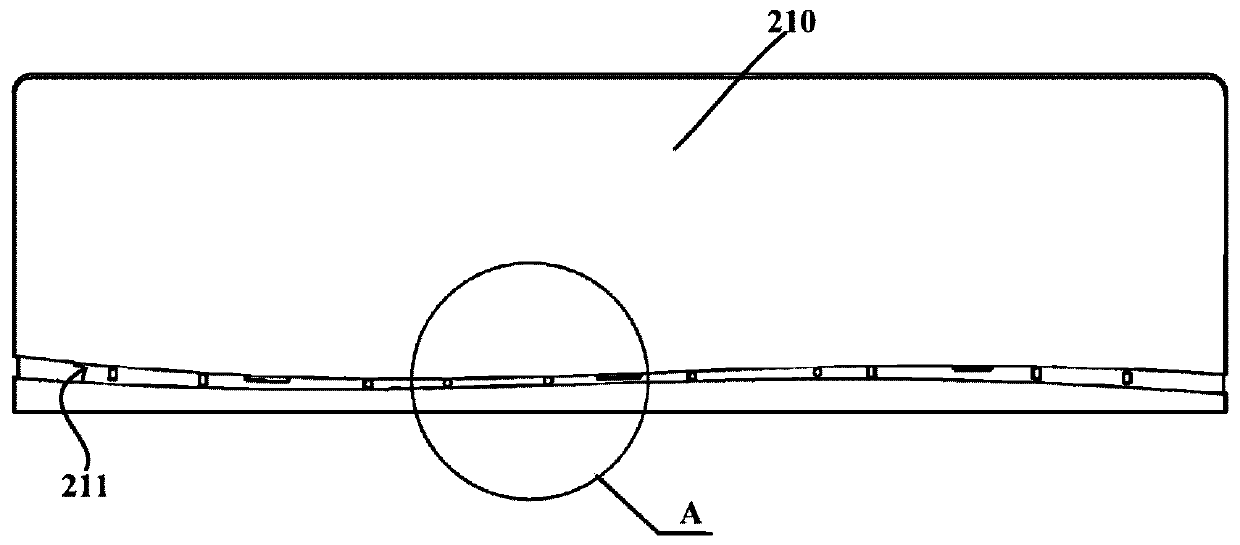

[0035] This embodiment first provides a panel assembly 200 of an air conditioner 10. In some embodiments, the air conditioner 10 can be a split air conditioner, and the split air conditioner generally consists of an air conditioner indoor unit, an air conditioner outdoor unit, and connecting pipelines. composition. figure 1 is a schematic structural diagram of an indoor unit of an air conditioner 10 according to an embodiment of the present invention, figure 2 is a schematic block diagram of an air conditioner 10 according to an embodiment of the present invention, wherein figure 1 The structure shown omits components such as the indoor air outlet and the indoor air inlet of the air conditioner 10 . The housing 100 of the split type air conditioner also includes an indoor unit housing and an outdoor unit housing. The panel assembly 200 is used to form at least part of the housing 100 of the air conditioner 10, such as forming the front housing of the indoor unit. Indoor hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com