Patents

Literature

38results about How to "Avoid flow marks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

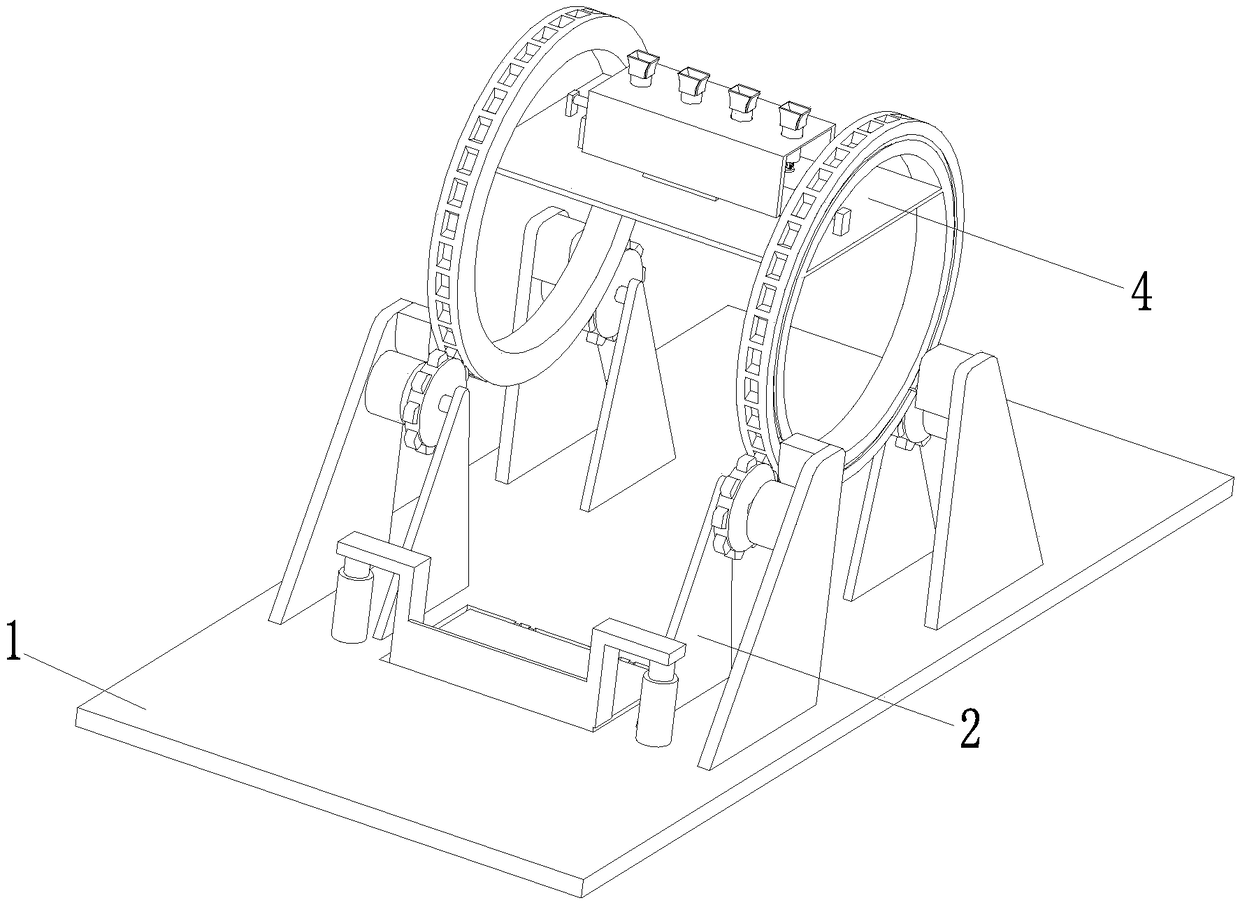

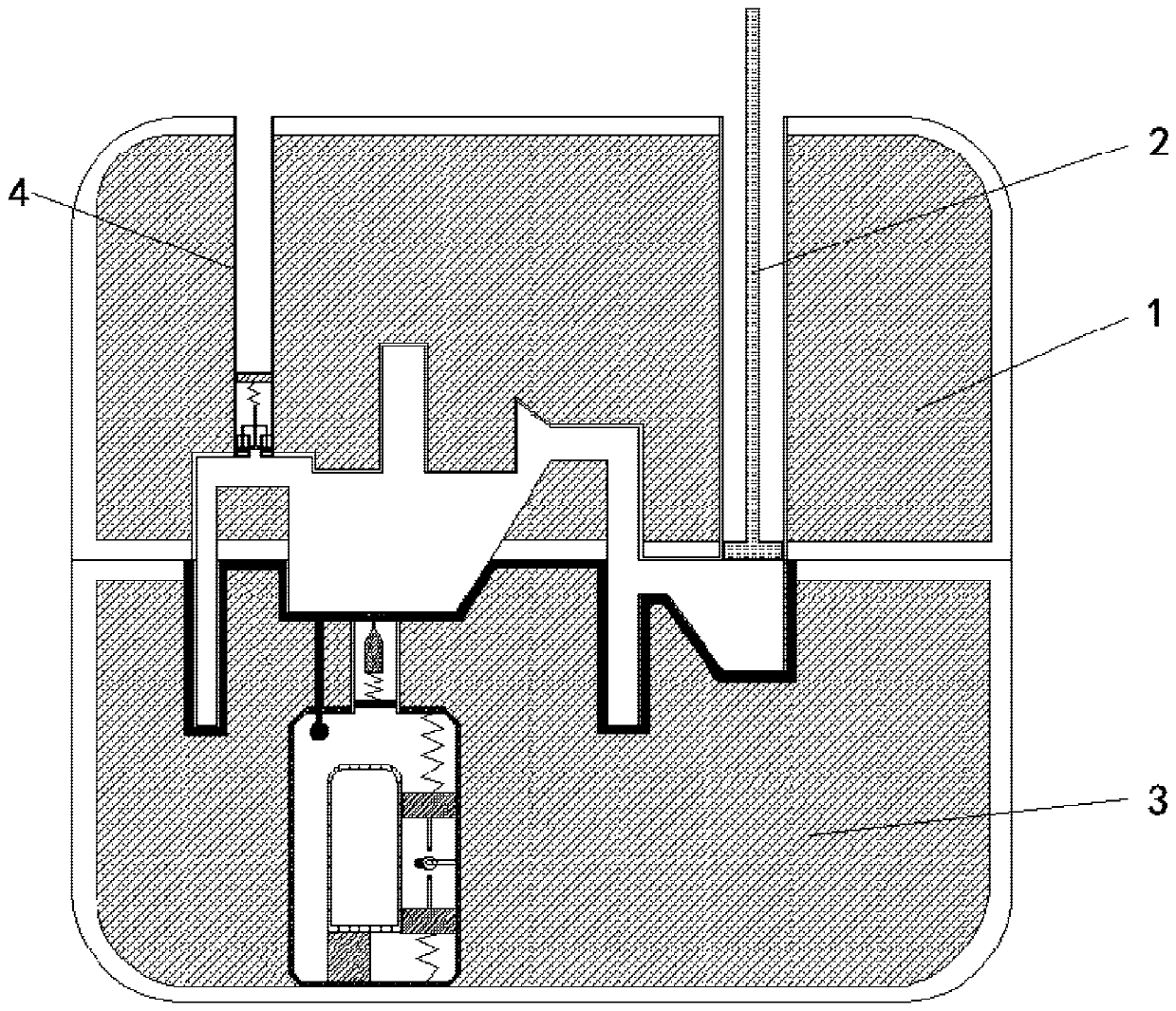

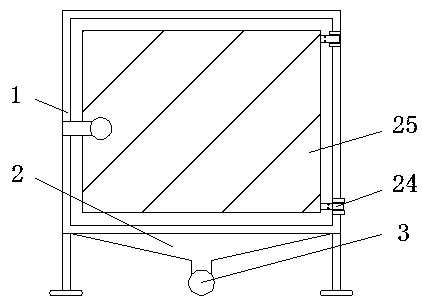

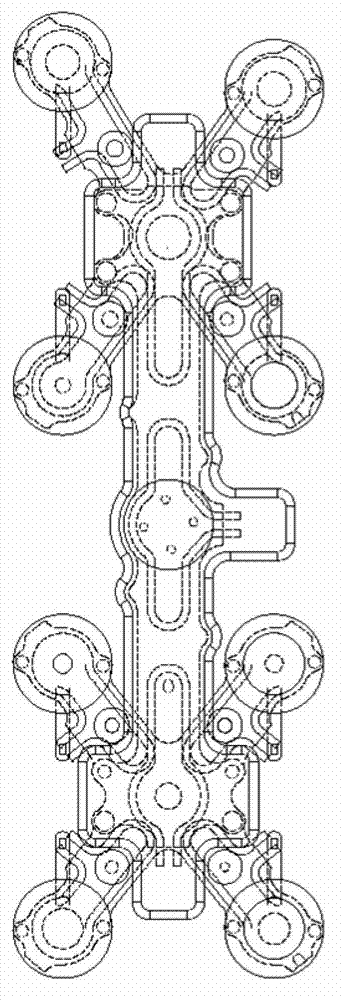

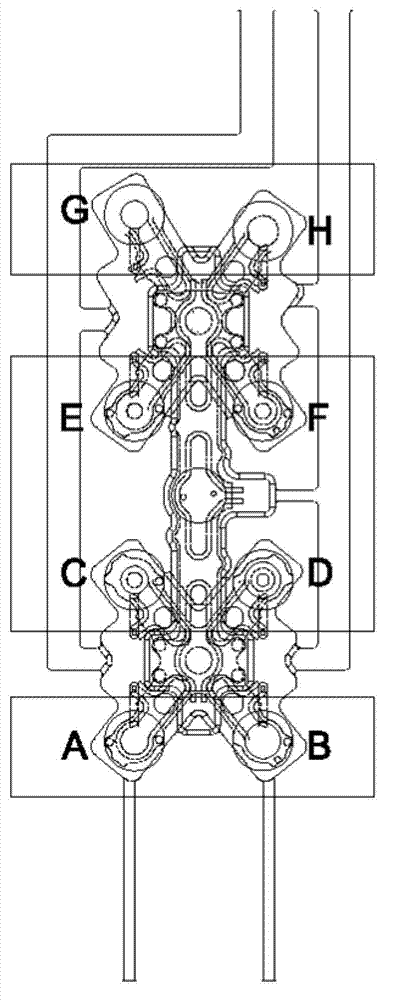

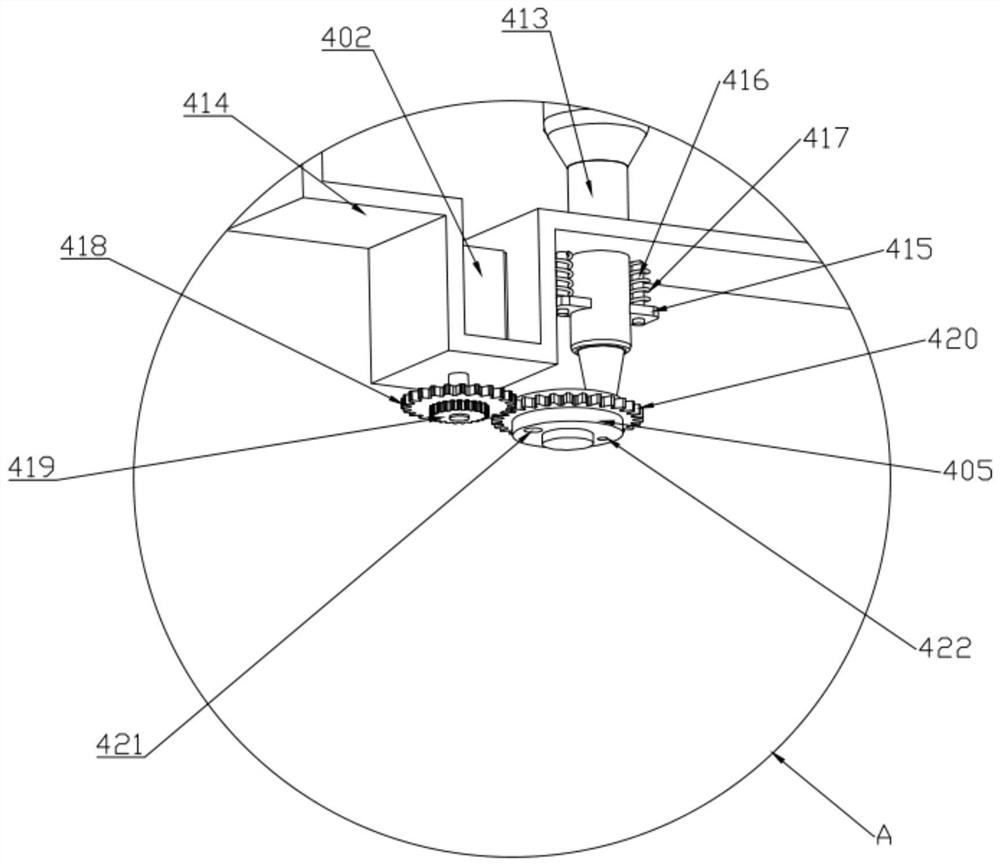

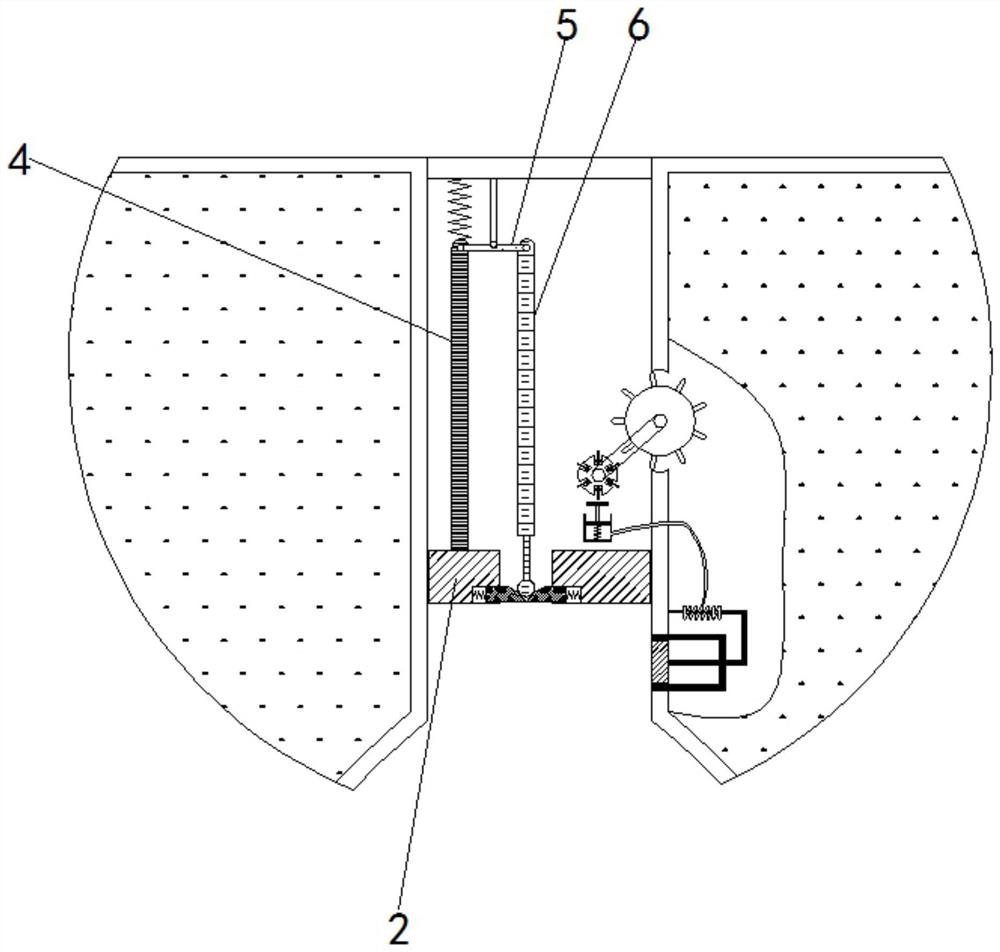

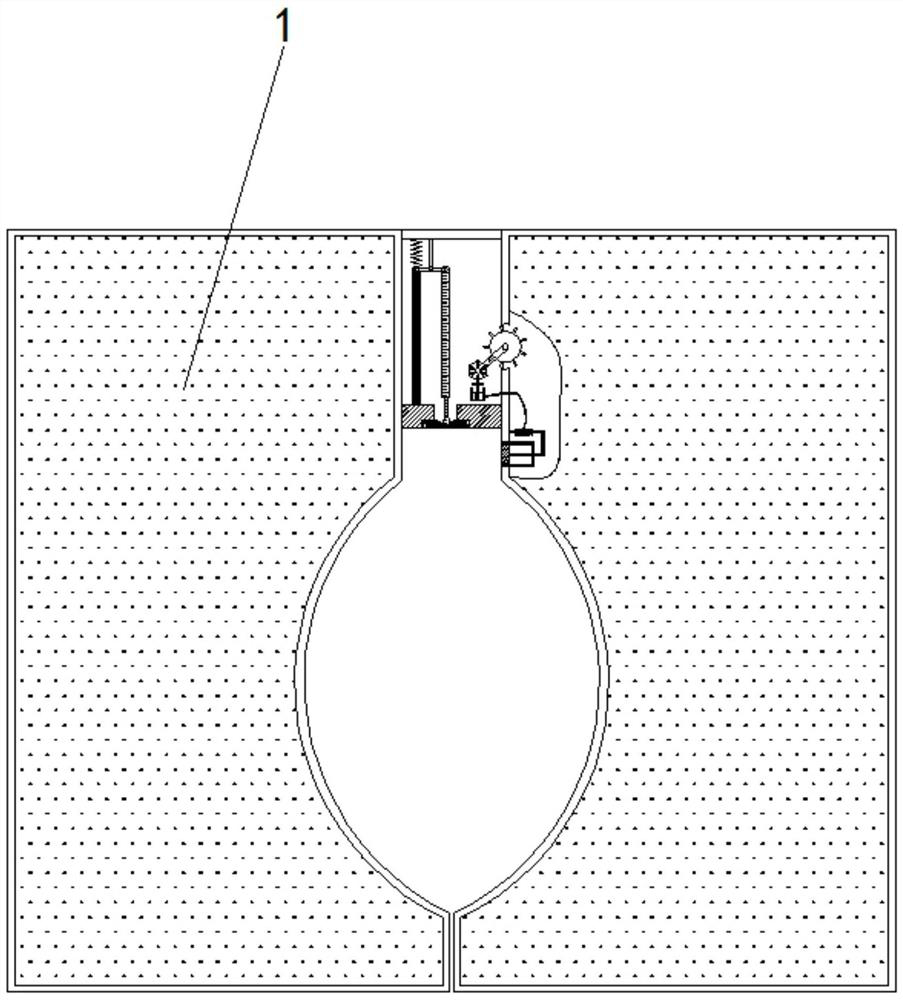

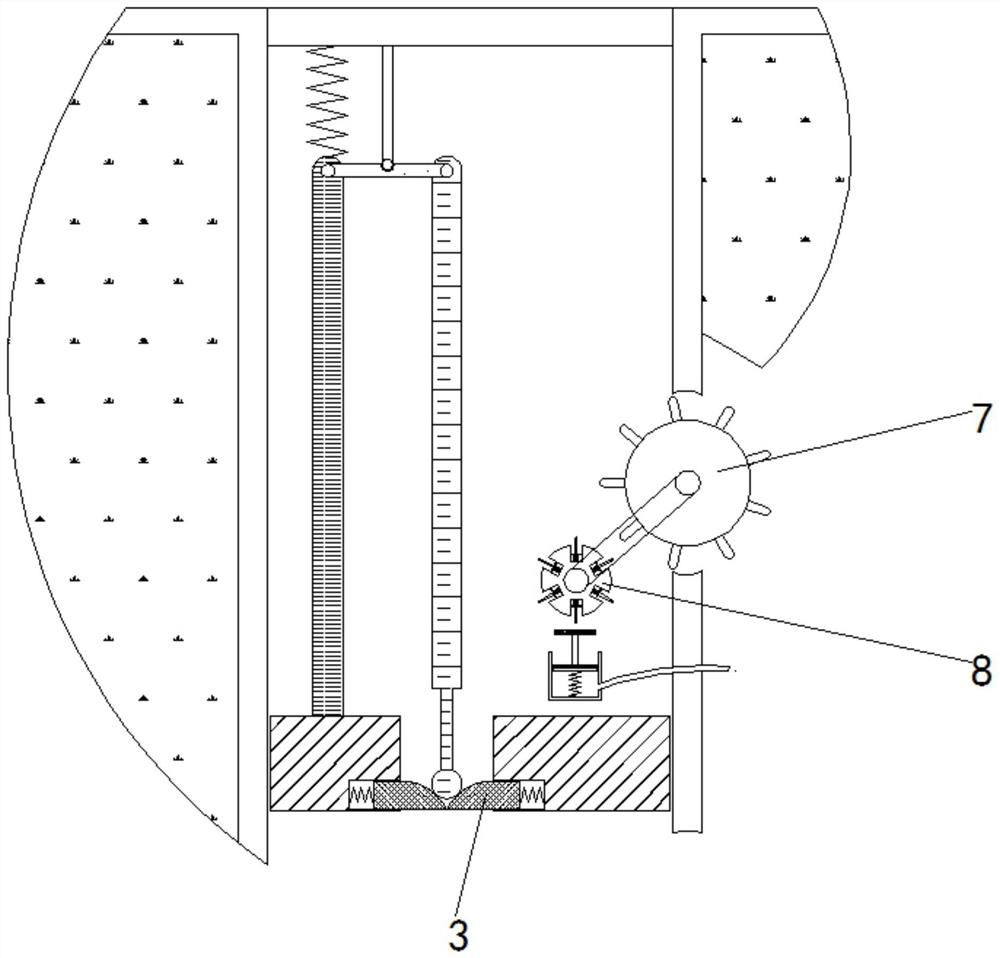

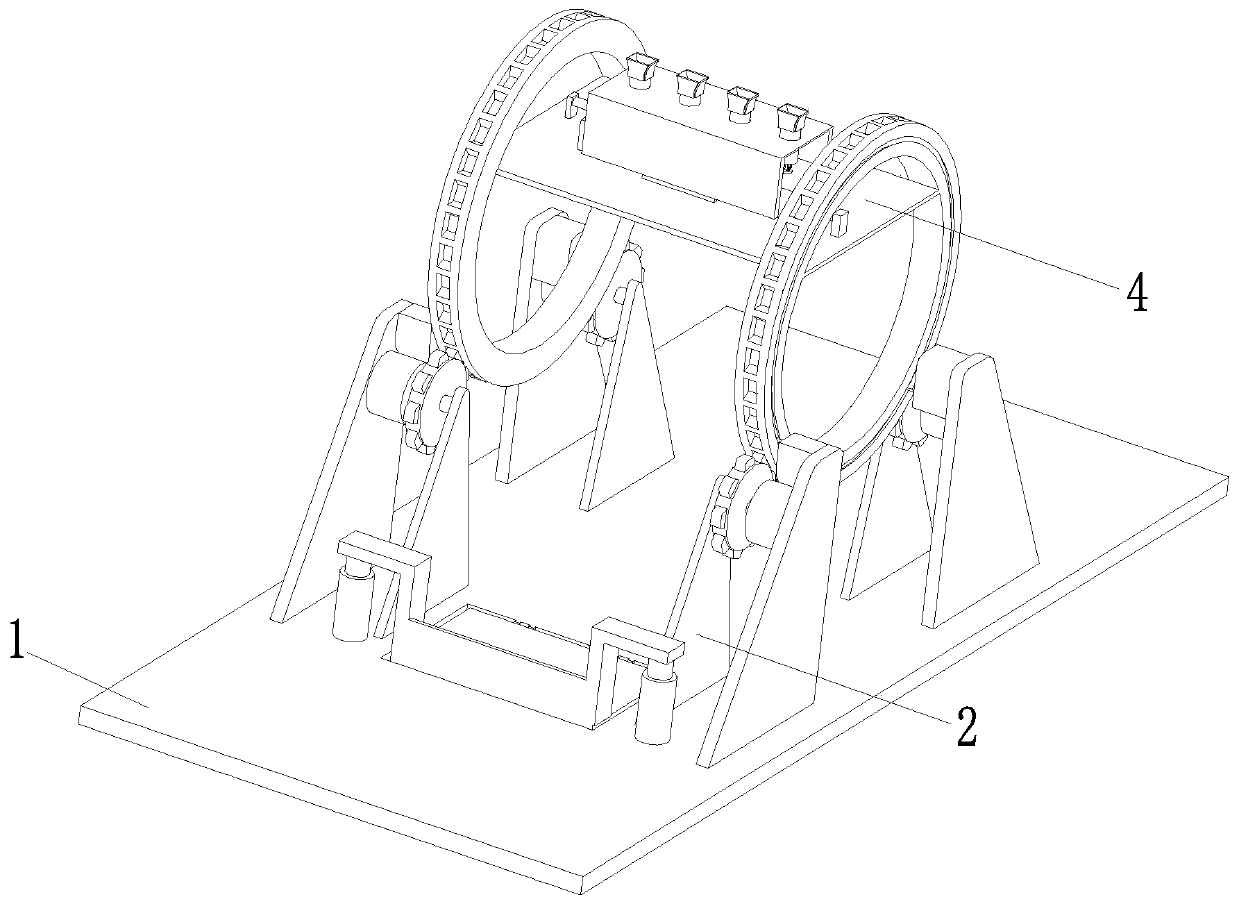

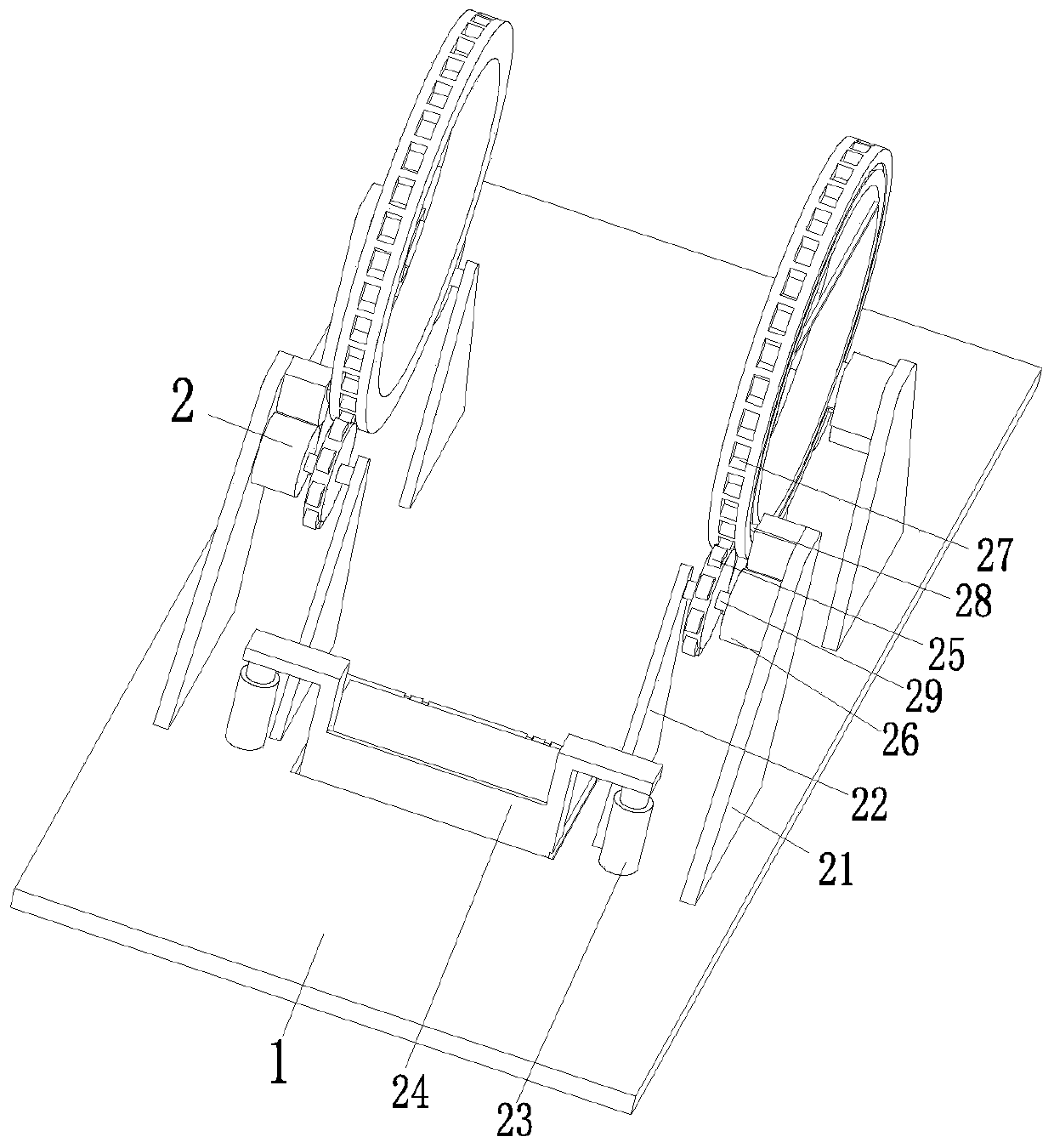

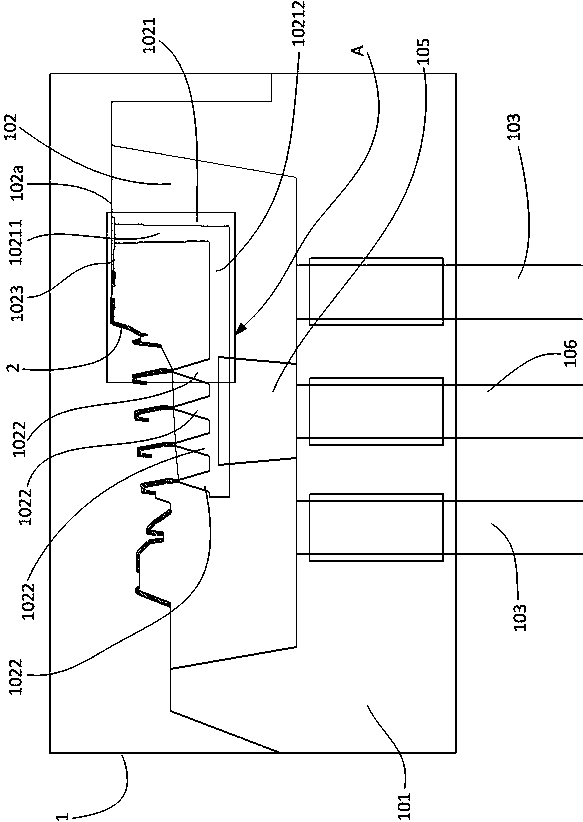

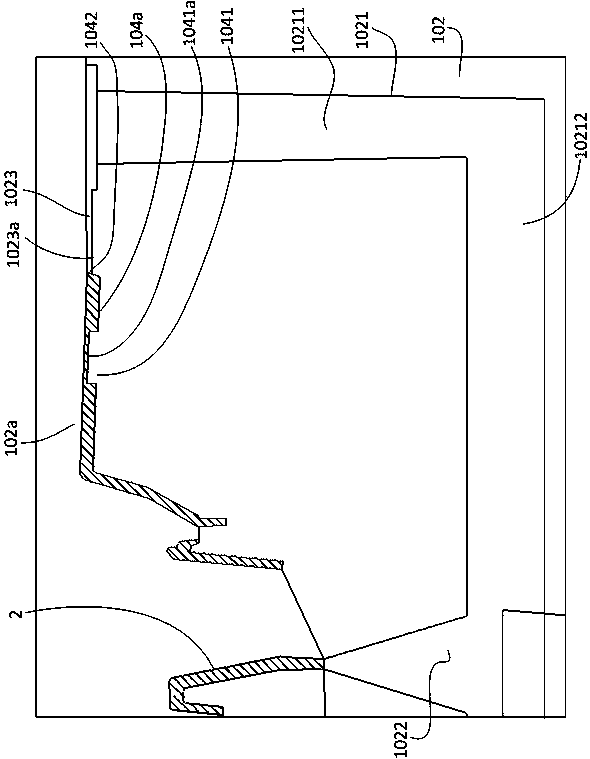

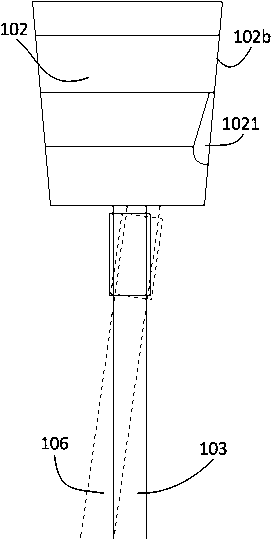

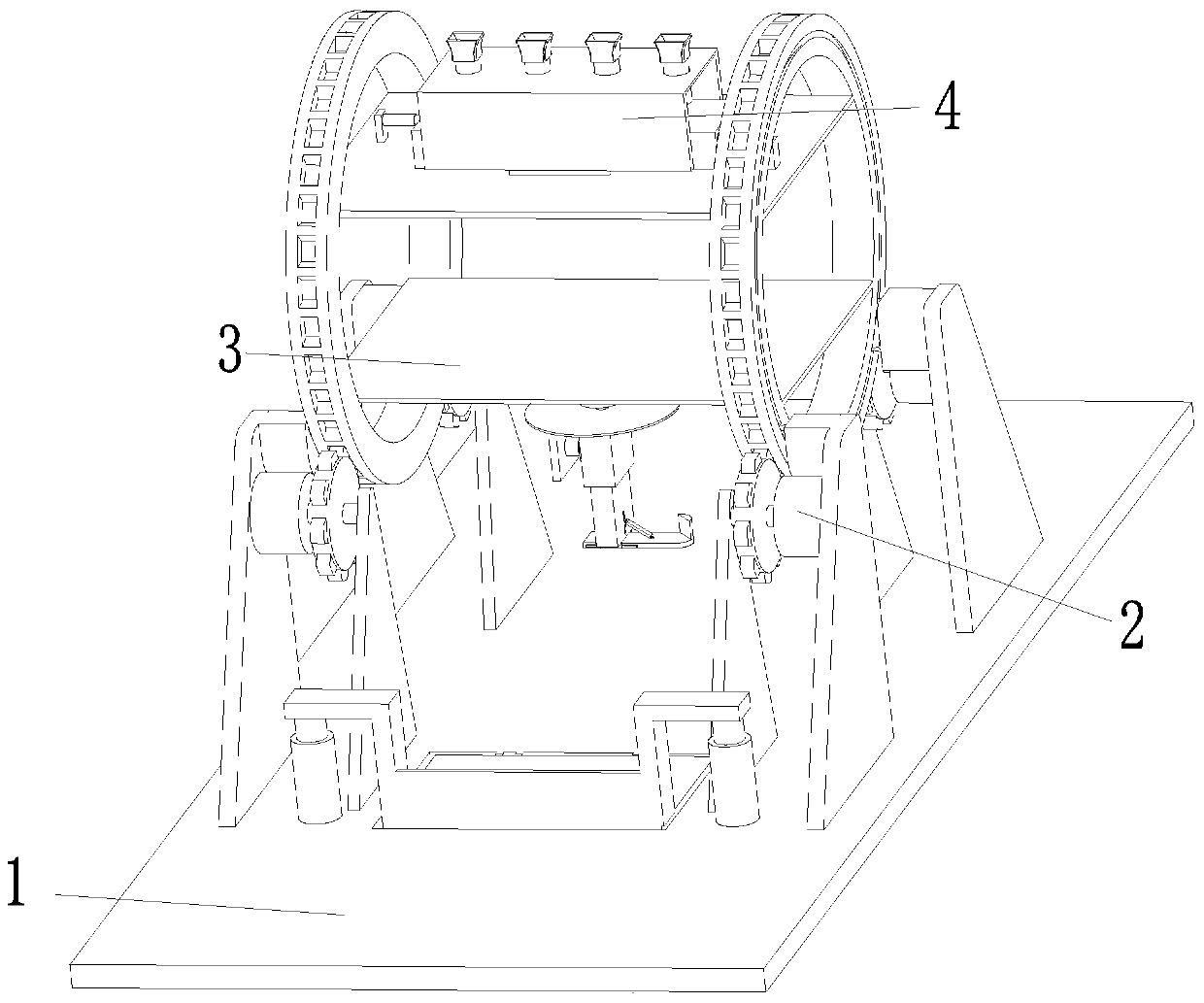

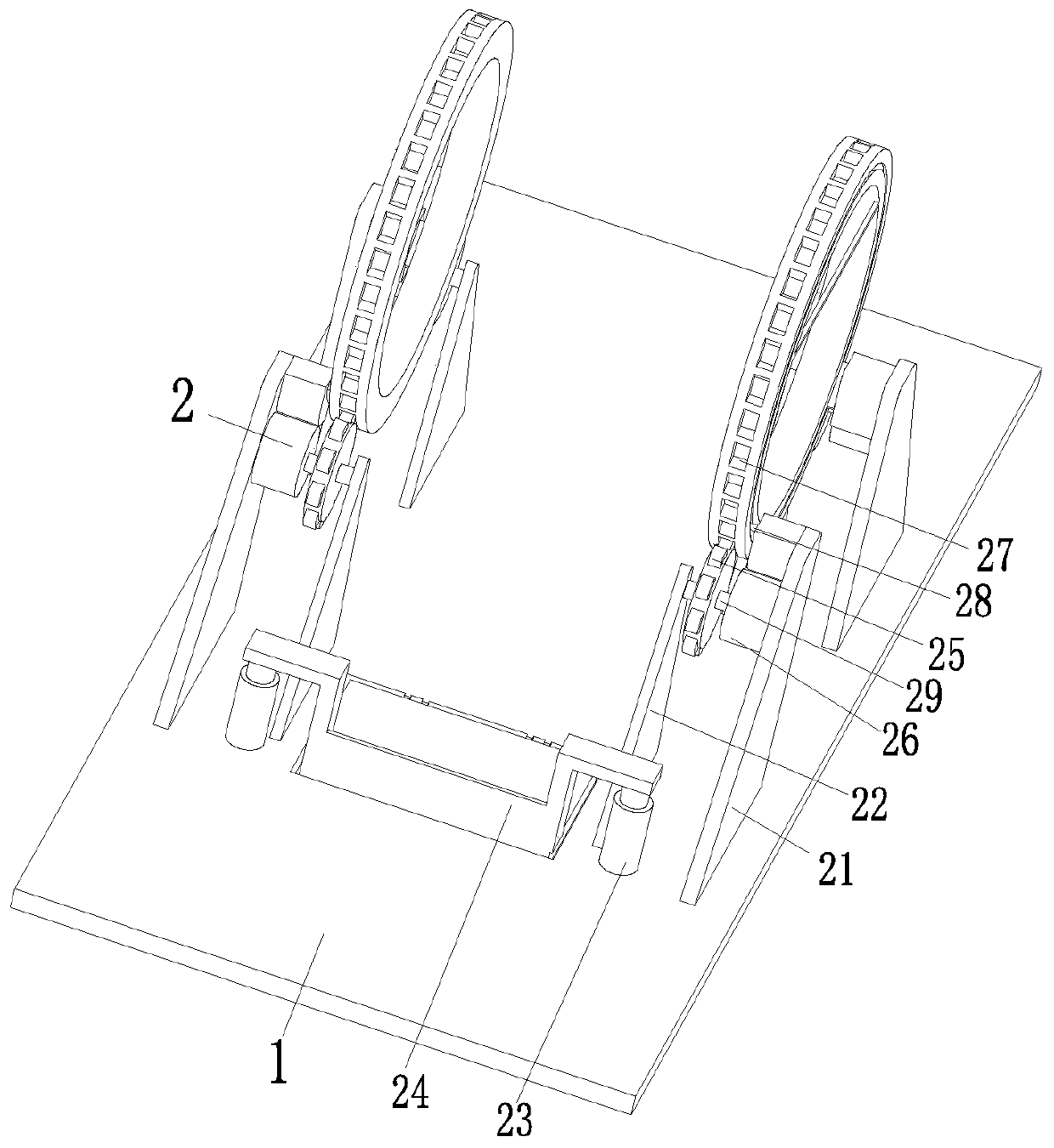

Equipment for spraying casting coating to surface of molding sand for sand mould casting

The invention relates to equipment for spraying casting coating to the surface of molding sand for sand mould casting. The equipment comprises a bottom plate, a tumbling device and a coating device, ahole is formed in the middle portion of the front end of the bottom plate, the tumbling device is mounted on the upper end surface of the middle portion of the bottom plate, and the coating device isinstalled on the inner side face of the upper end of the tumbling device. The invention can solve the problems that an existing spraying machine cannot prevent flow marks and accumulation of coating,a nozzle cannot be rotated and tilted, the coating cannot cover the surface of a sand mould from all directions, and the spraying angle cannot be adjusted at will; and the function of automatically spraying the casting coating to the surface of the molding sand can be realized.

Owner:微山县汉润机械制造有限公司

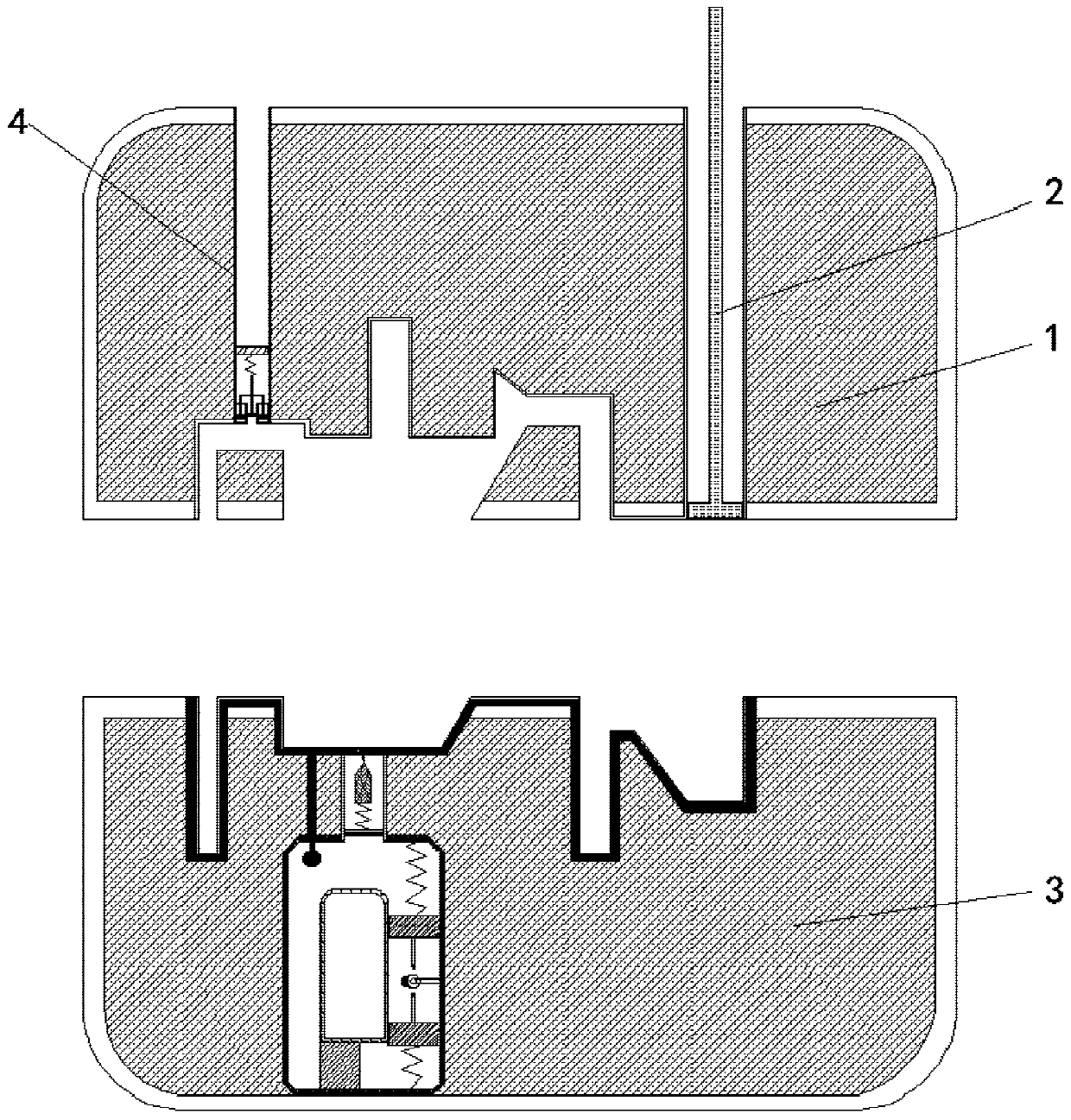

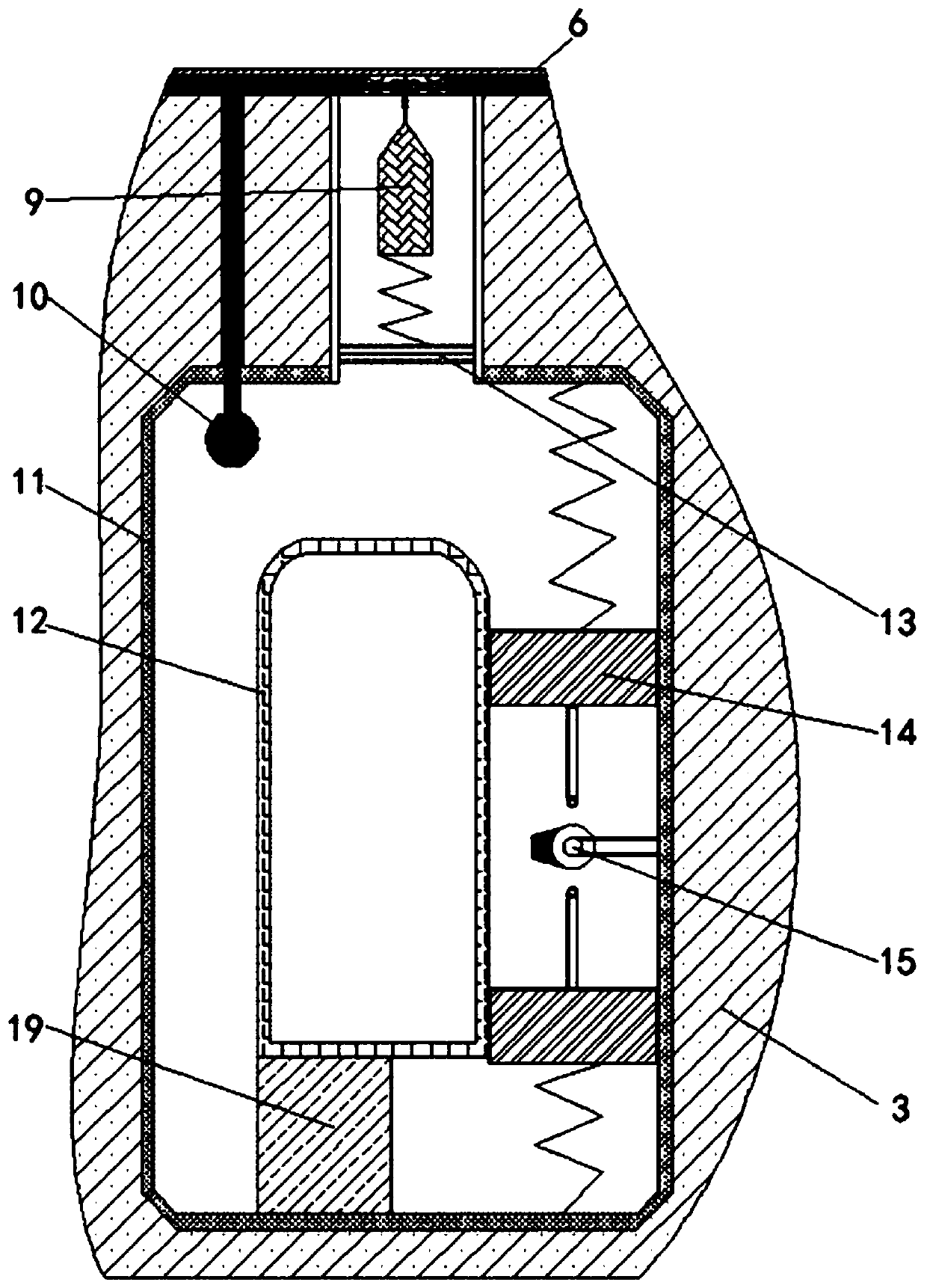

Gas discharge mold used during aluminum alloy casting

The invention discloses a gas discharge mold used during aluminum alloy casting. The gas discharge mold comprises an upper mold base, wherein a liquid pressing rod is arranged at the top of the uppermold base in a penetrating and inserting manner; a demolding pipe is arranged at the position, positioned on the left side of the liquid pressing rod, of the top of the upper mold base in a penetrating and inserting manner; the sides, back to each other, of two gears are rotationally connected with a vibration wheel; a water baffle is arranged at the bottom of a vibration toothed rod; a mercury box is arranged at the bottom of the water baffle; a heat conduction block is arranged at the top of the mercury box in a penetrating and inserting manner; a circulation body is arranged in the mercurybox; the right side of the circulation body is in sliding connection with gas pushing plates; and a cam is arranged between the two gas pushing plates. According to the gas discharge mold used duringaluminum alloy casting, through cooperative usage of the circulation body and the mercury box, the effects that gas is removed in the liquid aluminum alloy cooling process, the situation that gas bubbles cannot rush out of aluminum alloy liquid due to the too small volume, and consequently a cavity skin is formed on the surface of a casting are avoided.

Owner:陈善福

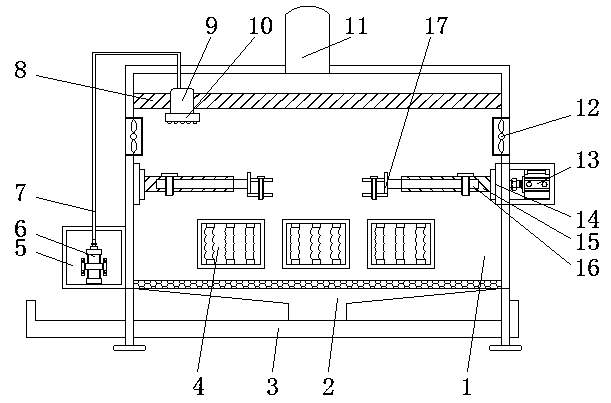

Multi-angle paint spraying device for production of wooden products

PendingCN109332068ACreate pollutionEasy to cleanLiquid spraying apparatusSpray boothsWastewaterEngineering

The invention discloses a multi-angle paint spraying device for production of wooden products. The multi-angle paint spraying device for production of the wooden products comprises a paint spraying booth and a door spindle; a discharge outlet is formed in the lower end of the paint spraying booth; a discharge pipe is arranged at the lower end of the discharge outlet; a heating pipe is inlaid at the lower end of the front side of the paint spraying booth; the lower end of the left side of the paint spraying booth is connected with a paint tank which is internally provided with a booster pump; apaint pipe is fixed to the upper end of the booster pump; a sliding track is arranged at the upper end of the interior of the paint spraying booth; a sliding block is arranged on the left side of thefront side of the sliding track; and a paint spraying valve is inlaid at the lower end of the sliding block. According to the multi-angle paint spraying device for production of the wooden products,the paint spraying booth is arranged, mesh holes are formed in the lower end of the paint spraying booth, waste paint generated in the paint spraying process can permeate through the mesh holes, wastewater can also permeate into the discharge pipe via the mesh holes when the interior is cleaned, and therefore, both the waste paint and the waste water can be discharged and treated in a unified way.

Owner:湖州南浔蚕乡原牧食品有限公司

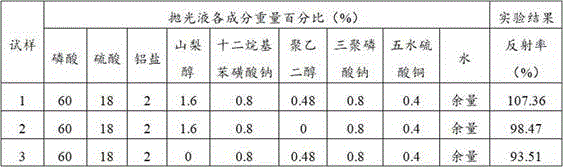

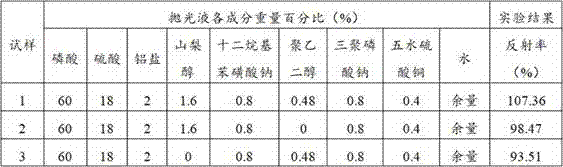

Smokeless polishing solution for aluminum products

ActiveCN107177848AIncrease brightnessOvercoming the problem of producing toxic nitrogen oxidesPolyethylene glycolPhosphoric acid

The invention discloses a smokeless polishing solution for aluminum products. The smokeless polishing solution is prepared from, by weight, 50%-65% of phosphoric acid, 15%-20% of sulfuric acid, 1%-3% of aluminum salt, 10%-15% of water and 3%-10% of additives. The additives comprise, by weight, 15%-20% of sorbitol, 8%-12% of sodium dodecyl benzene sulfonate, 2%-6% of polyethylene glycol, 8%-10% of sodium tripolyphosphate, 3%-8% of cupric sulfate pentahydrate and 48%-55% of water. By adopting the smokeless polishing solution, the polishing effect of a traditional three-acid polishing solution can be basically achieved, no yellow smoke is generated, and no flow mark is generated when drip hanging is conducted for a long time.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

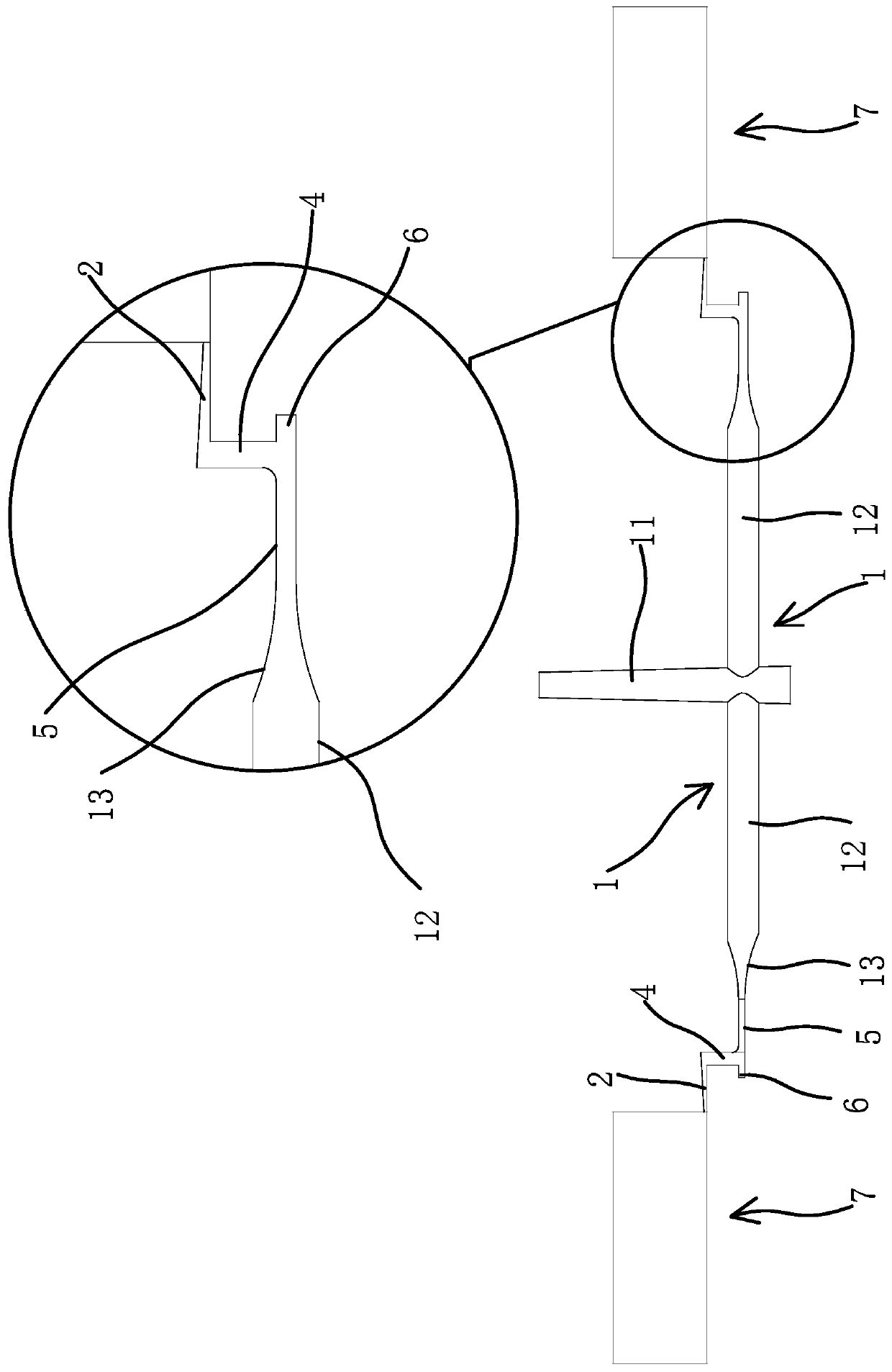

Self-flow-disturbing injection mold pouring system

The invention provides a self-flow-disturbing injection mold pouring system, belongs to the technical field of injection molding processing, and solves the technical problem that existing thick-walledtransparent plastic parts are susceptible to flow marks and other injection molding defects. The self-flow-disturbing injection mold pouring system comprises a tubular runner for being connected withan external plastic melt and a gate for enabling the runner to communicate with a mold cavity, wherein a plurality of pin fins arranged at intervals are arranged in the gate. The system is characterized in that the runner communicates with the gate by a flat buffer pipe for leading the plastic melt to flow upwards, the gate is used for guiding the plastic melt to flow downwards and is flat tubular, the pin fins are arranged in at least one row, and each row of the pin fins is arranged in the width direction of the gate. The flow marks of the thick-walled transparent plastic parts are effectively prevented by improvement of the pipe structure and the arrangement manner of the pin fins of the pouring system.

Owner:ZHEJIANG SAIHAO IND CO LTD

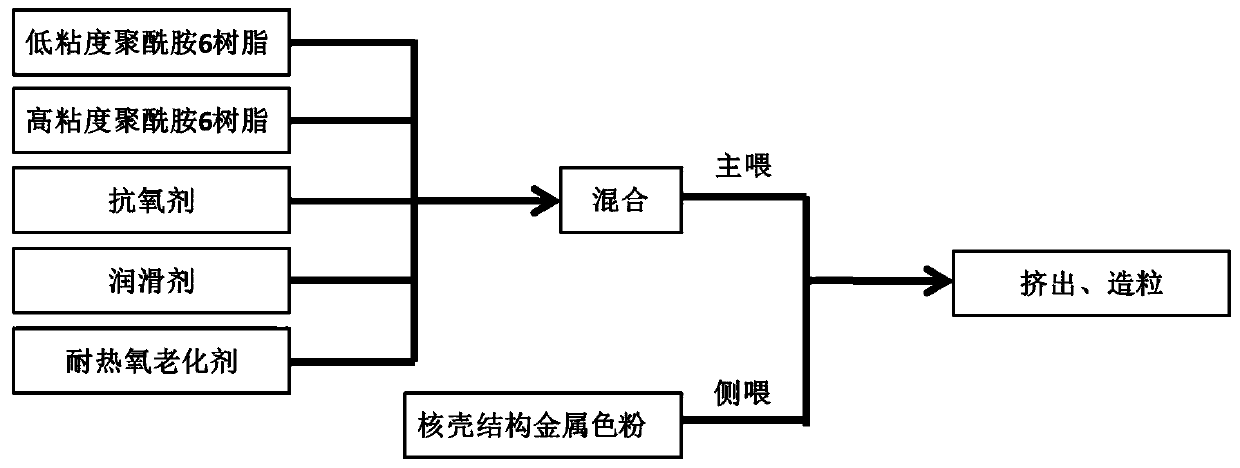

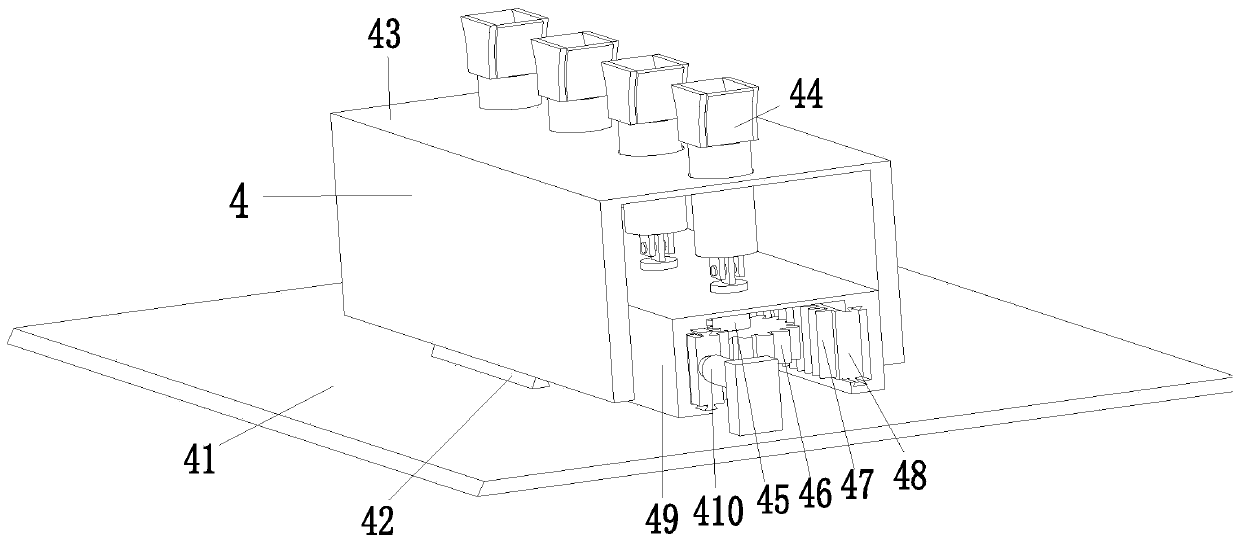

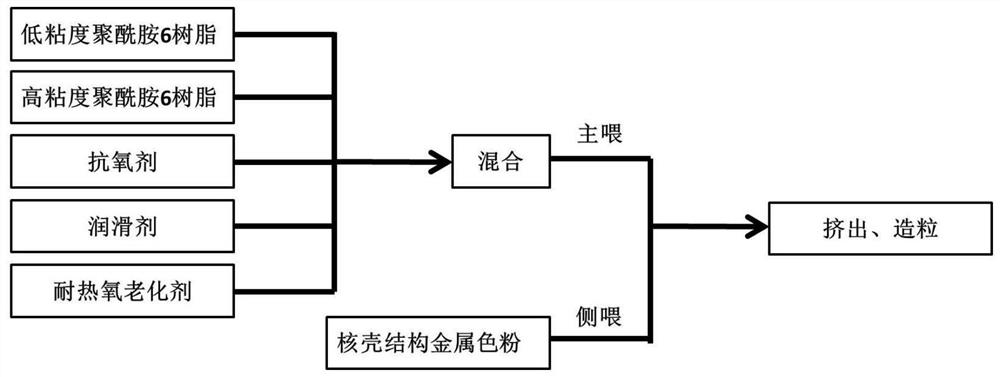

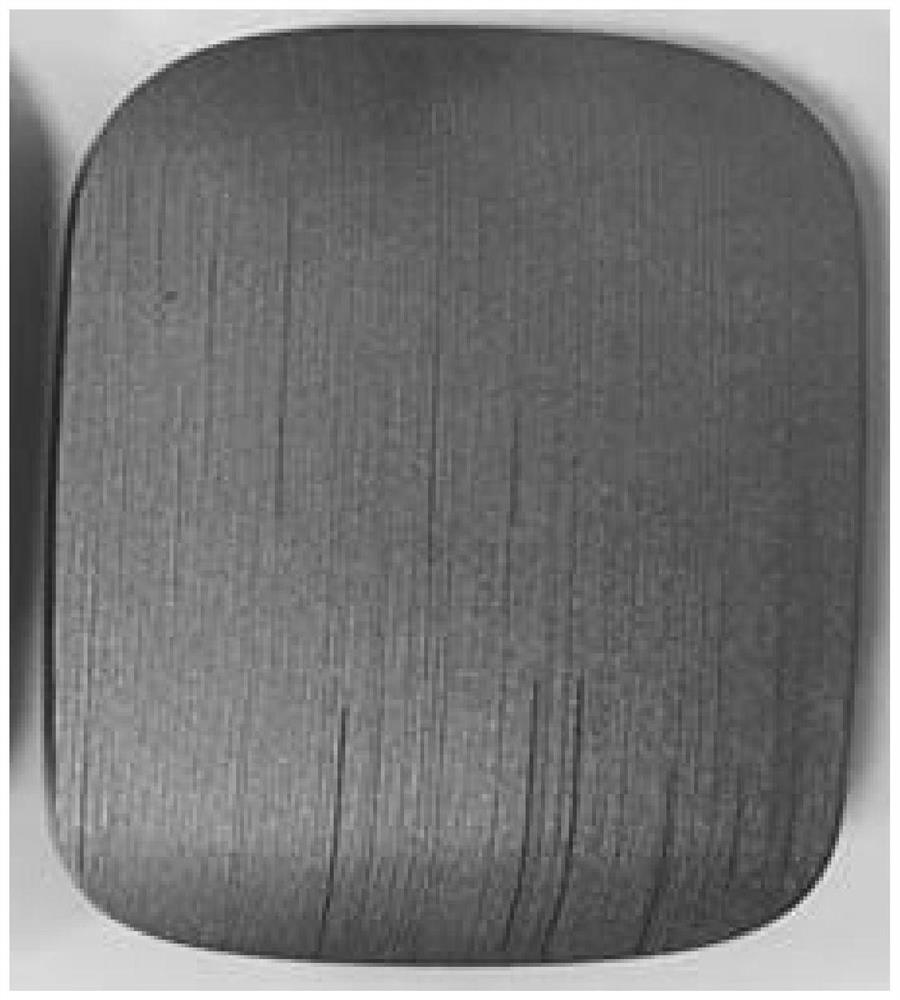

Polyamide material with metal texture and preparation method thereof

The invention provides a polyamide material and a preparation method thereof. The core-shell-structured metal toner spraying-free polyamide material is prepared from the following raw materials: low-viscosity polyamide 6 resin, high-viscosity polyamide 6 resin, an antioxidant, a lubricant, a thermo-oxidative aging resisting agent and core-shell-structured metal toner. The spraying-free polyamide material prepared from the core-shell-structured metal toner has excellent mechanical properties and processability, and can be applied to the fields of automobiles and household appliances such as automobile exterior decorations, air conditioner decoration strips, and small household appliance exterior decoration structures.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

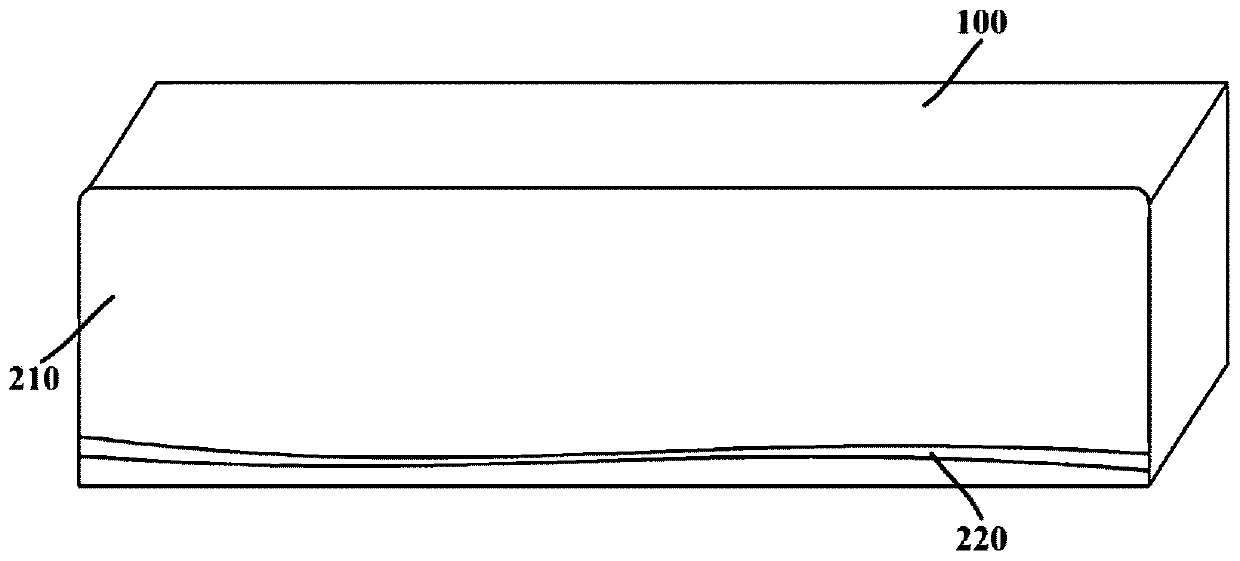

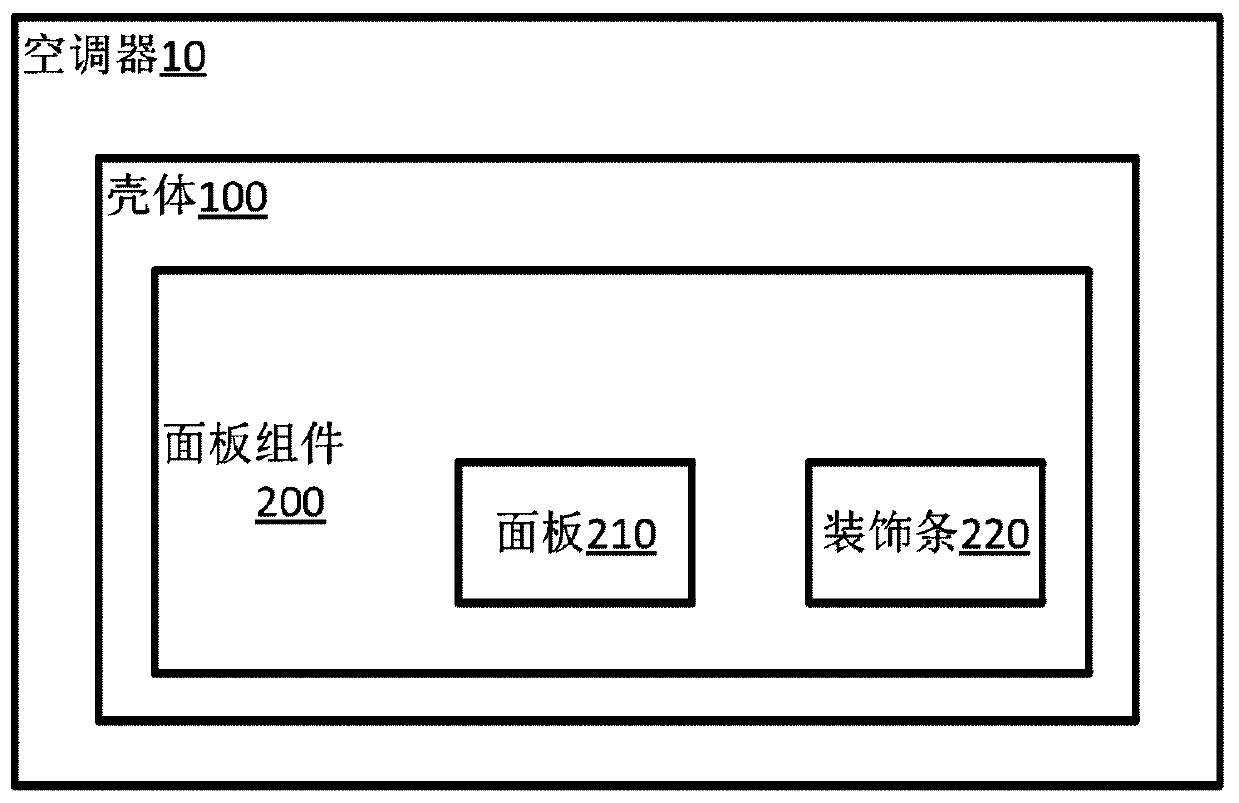

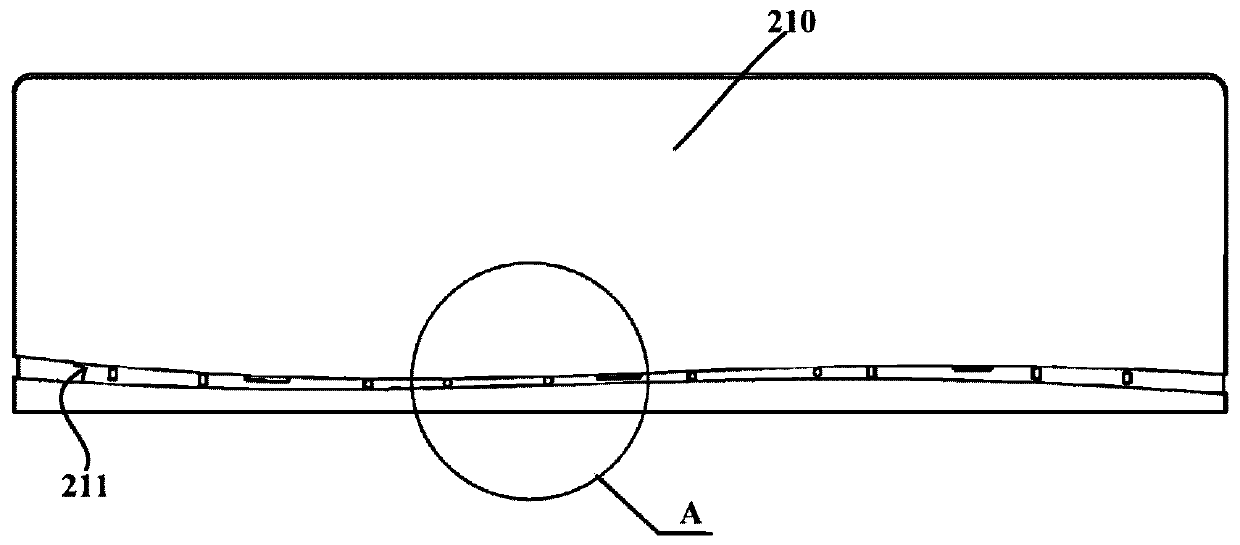

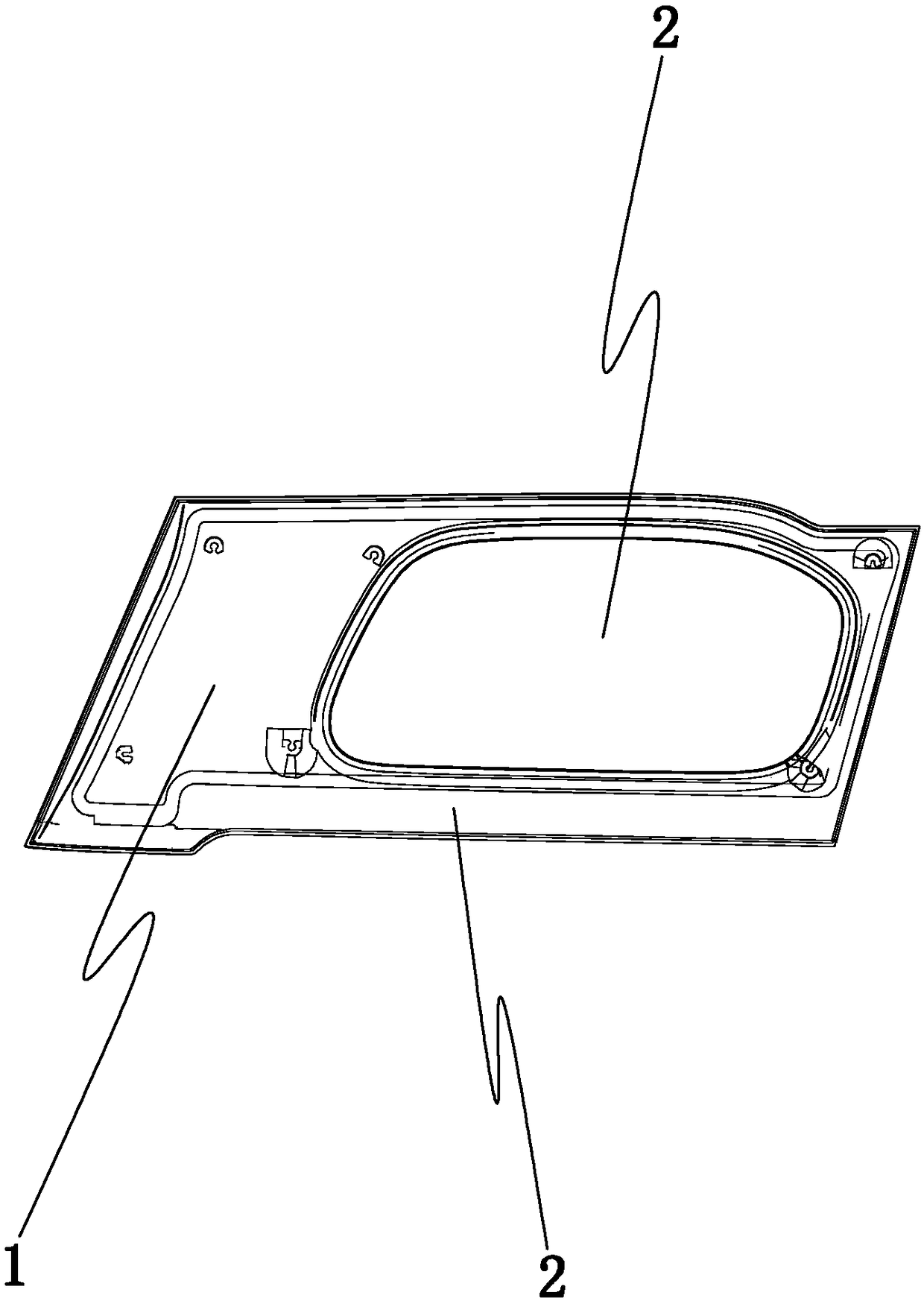

Air conditioner panel assembly and air conditioner

ActiveCN110220292AIncrease smoothnessEnhance metallic color effectHeating and ventilation casings/coversColor effectEngineering

The invention provides an air conditioner panel assembly. The air conditioner panel assembly comprises a panel and a decoration strip, wherein a decoration strip groove is formed in the front surfaceof the panel; the decoration strip is produced through injection molding of a metal texture spraying-free material and is mounted in the decoration strip groove; a plurality of clamping buckles whichare raised backwards are arranged on one side, facing to the decoration strip groove, of the decoration strip; and clamping holes which are in one-to-one correspondence to the plurality of clamping buckles and are matched with the clamping buckles are respectively formed in positions, opposite to the plurality of clamping buckles located in the decoration strip, in the decoration strip groove. According to the air conditioner panel assembly, the size of each clamping buckle in a transverse direction of the decoration strip is smaller than a distance between an upper end surface highest point and a lower end surface lowest point of the clamping buckle in a vertical direction, so that the generation of flow marks on the decoration strip in the injection molding process is generated, so thatthe smoothness degree of the surface of the decoration strip is improved; the process of removing the flow marks is avoided; and the metal color effect of the surface of the decoration strip is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Spraying-free material and manufacturing method of spraying-free ornament for automotive interiors

The invention discloses a spraying-free material. The spraying-free material comprises the following components in percentage by mass: 80-95% of matrix resin, 0.1-3% of effect toner, 0.1-3% of basic toner, 1-3% of auxiliary master batch and 0-20% of filler; and the spraying-free material has various different color effects and has good toughness. The invention further discloses a manufacturing method of a spraying-free ornament for automotive interiors. According to the manufacturing method, a double-color forming mold is adopted; a movable mold of the double-color forming mold is provided with a first color forming area and a second color forming area. The manufacturing method comprises the following steps that: S1, a material A and a material B are weighed correspondingly, the material Ais the spraying-free material, and the material B is an ornament framework injection molding material; S2, respectively putting the material A and the material B into corresponding gun barrels, closing the mold, and carrying out injection molding on the material A in the first color forming area to form an ornament surface layer; and S3, opening the mold, after rotating the mold to change the position of the mold, closing the mold again, carrying out injection molding on the material B on the second color forming area so as to form an ornament framework. The technological process is simple, and flow marks and weld line defects can be avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

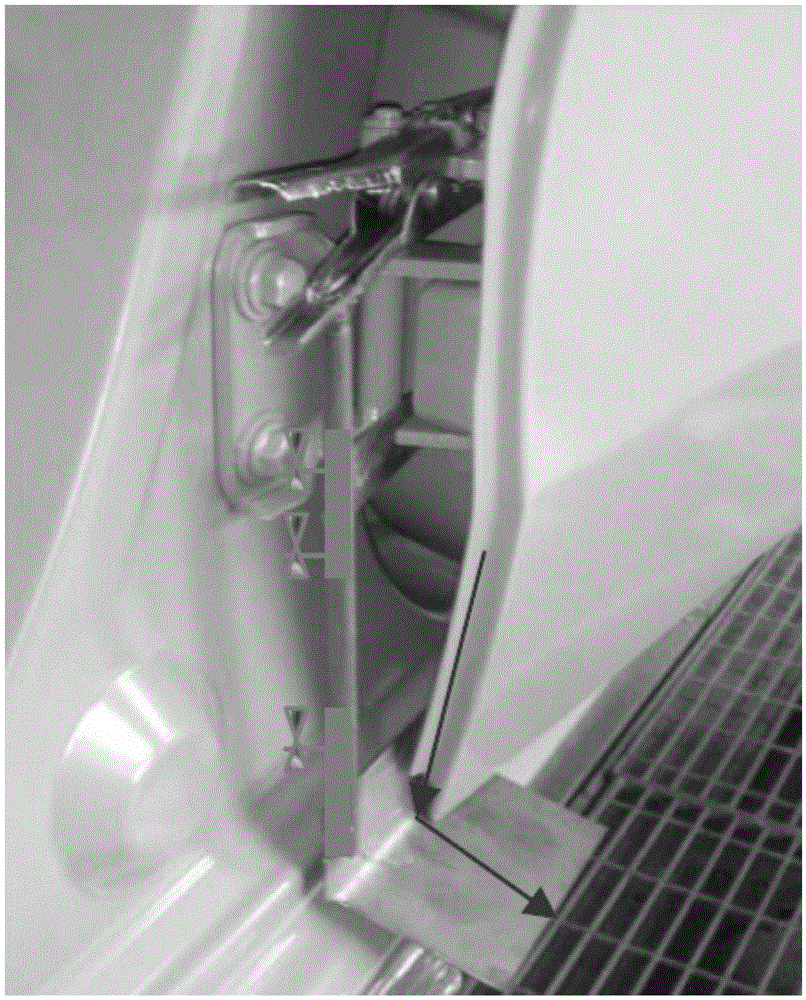

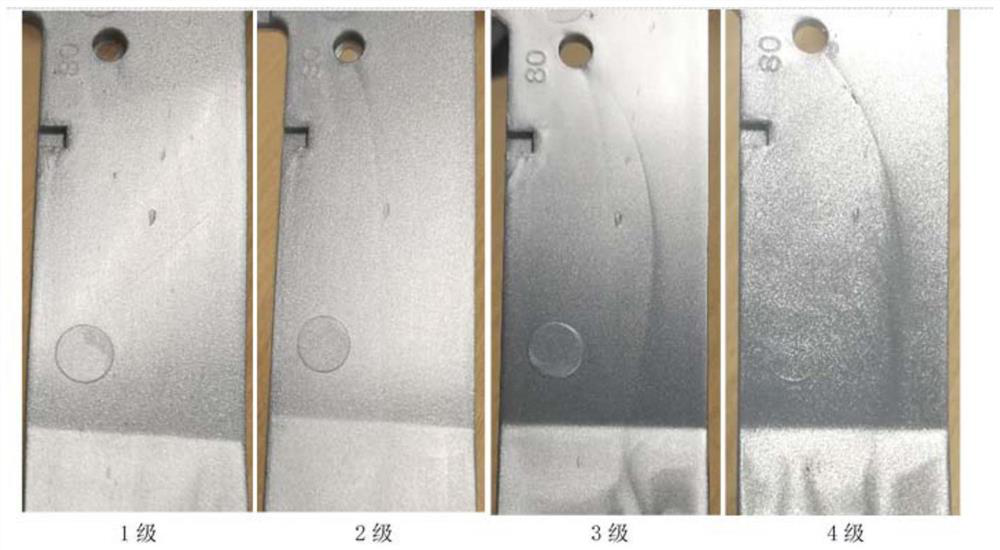

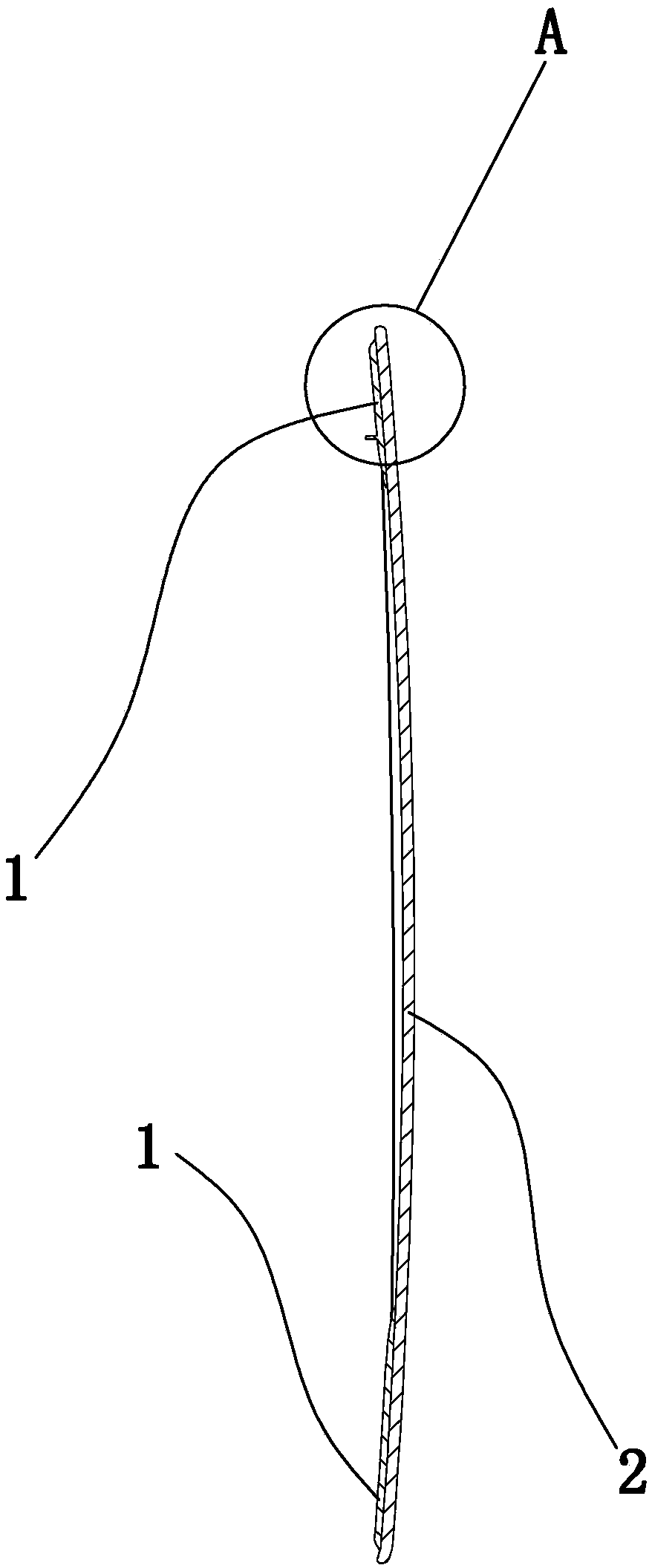

Auxiliary drainage tool and method for preventing electrophoresis flow marks from being generated on surface of automobile body

The invention discloses an auxiliary drainage tool and a method for preventing electrophoresis flow marks from being generated on the surface of an automobile body. The auxiliary drainage tool comprises a fixing device, a drainage liquid collection plate and a hanging rod. The fixing device is used for being fixed to the automobile body in use. The drainage liquid collection plate is used for guiding electrophoretic paint flowing out of cracks of the automobile body in the roasting process to be away from the automobile body. The hanging rod is connected with the fixing device and the drainage liquid collection plate. According to the auxiliary drainage tool, electrophoretic liquid squeezed out of the cracks of a metal plate of the automobile body in the roasting process of the automobile body can be converged and guided to be away from the automobile body through the fluid mechanics principle, and thus the flow marks are prevented from being generated on the outer surface of the automobile body.

Owner:CHERY AUTOMOBILE CO LTD

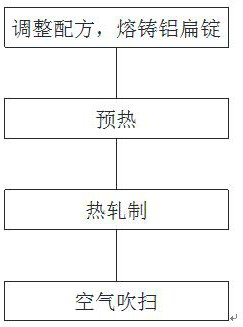

Method for producing 5052H32 aluminum alloy plate in short process

ActiveCN112831701AExpanded dynamic recrystallization temperature rangeReduce temperature sensitivityTemperature controlIngot

The invention discloses a method for producing a 5052H32 aluminum alloy plate in a short process, and belongs to the technical field of alloy machining. The method for producing the 5052H32 aluminum alloy plate in the short process comprises the following steps that S1, a formula is adjusted, and an aluminum slab ingot is cast, specifically, 200-300 ppm of Zr element is added to the alloy formula, and the aluminum slab ingot is cast; S2, preheating is performed, specifically, the soaking temperature of preheating is controlled to be 500 DEG C; S3, hot rolling is performed, specifically, rolling is performed by the aid of a 1+4 hot continuous rolling mill, and the rolling reduction, the rolling pass of hot rough rolling, the thickness and temperature of an intermediate plate blank at a hot rough rolling outlet, the parking holding temperature of the intermediate plate blank, and the temperature and rolling speed of a finish rolling outlet are set according to the thickness matching of a finished product during rolling; and S4, air purging is carried out. The technological process is shortened, and cold rolling is not needed; and during rolling, the characteristics of the hot rolling technology are fully exerted, and the metal microstructure and mechanical property control in the quality requirement of the aluminum plate strip finished product plate is carried out in the hot rolling procedure for cooperative control.

Owner:河南中孚高精铝材有限公司

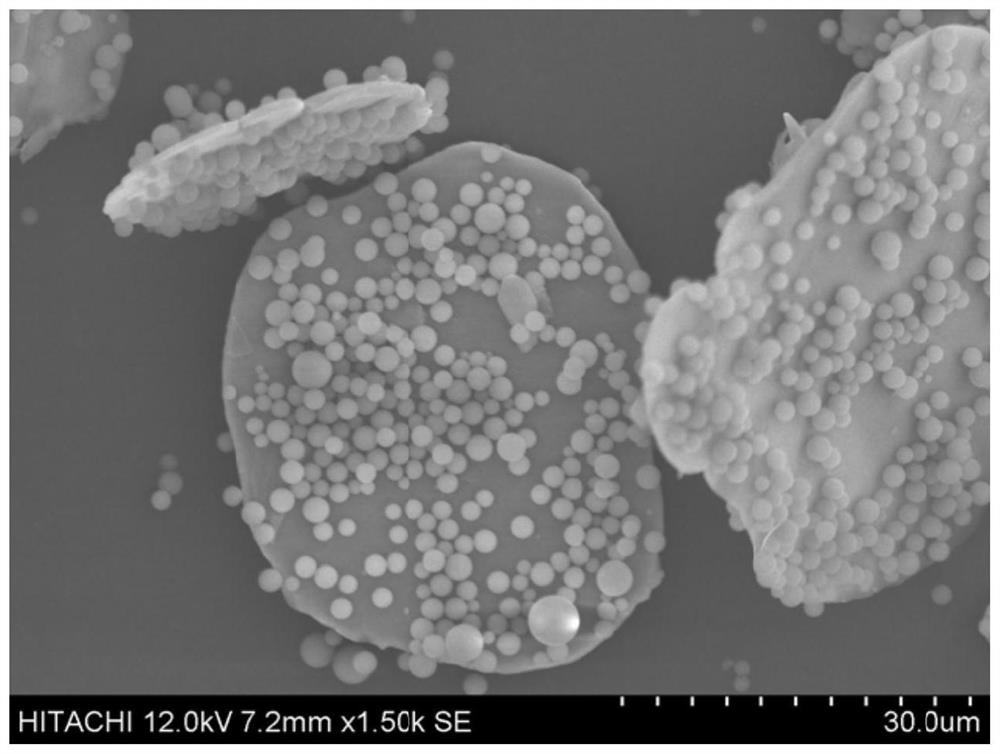

Spraying-free effect pigment as well as preparation method and application thereof

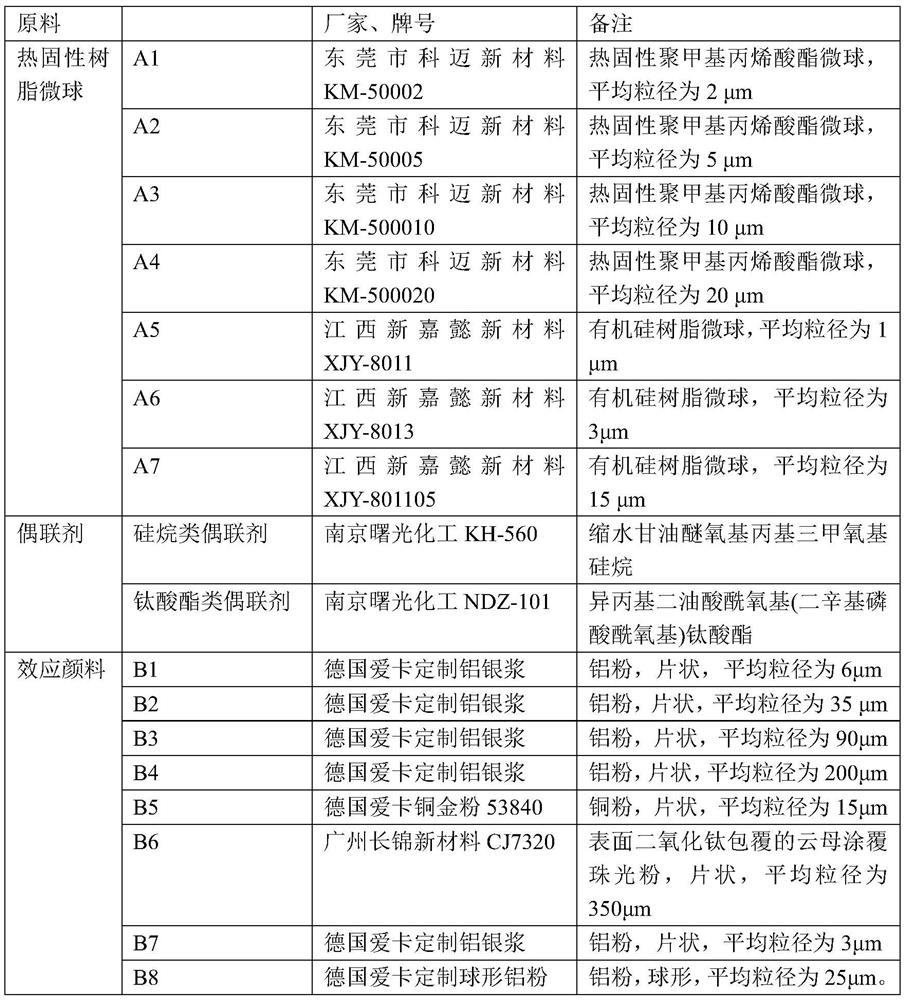

The invention discloses a spray-free effect pigment as well as a preparation method and application thereof. The spraying-free effect pigment comprises the following components in parts by weight: 100 parts of effect pigment, 10-200 parts of a coupling agent and 10-200 parts of thermosetting resin microspheres, the effect pigment is flaky, and the average particle size is 6-350 [mu] m; the ratio of the average particle size of the thermosetting resin microspheres to the average particle size of the effect pigment is 1: (3-100). The steric hindrance effect of the small-particle thermosetting resin is cooperated with improvement of compatibility, so that when the pigment with the spraying-free effect is added into a plastic matrix, a good spraying-free metal effect can be achieved, and the phenomena of weld marks and flow marks are avoided.

Owner:KINGFA SCI & TECH CO LTD

A composite material for high-gloss spray-free asa/pmma automobile air intake grille and its preparation method

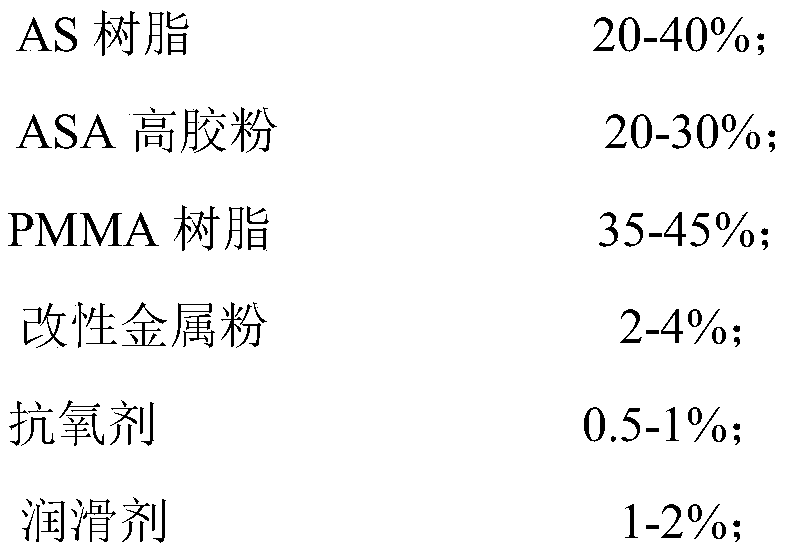

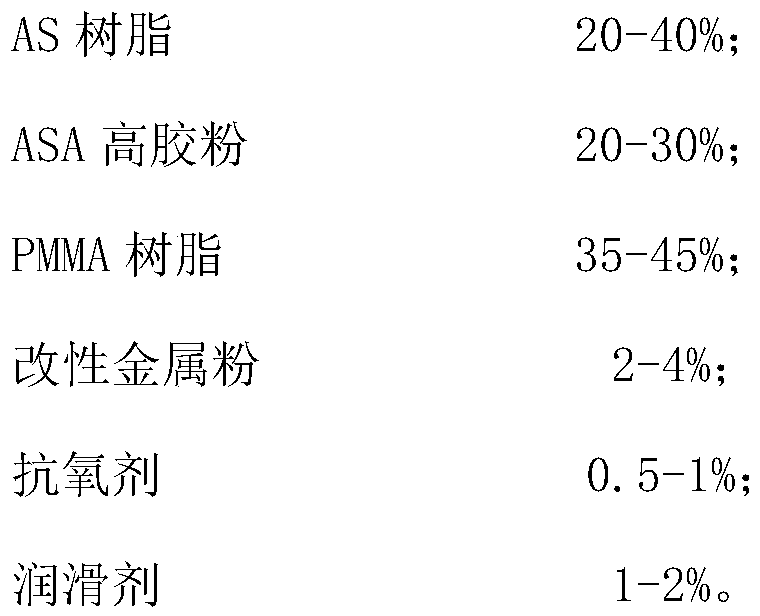

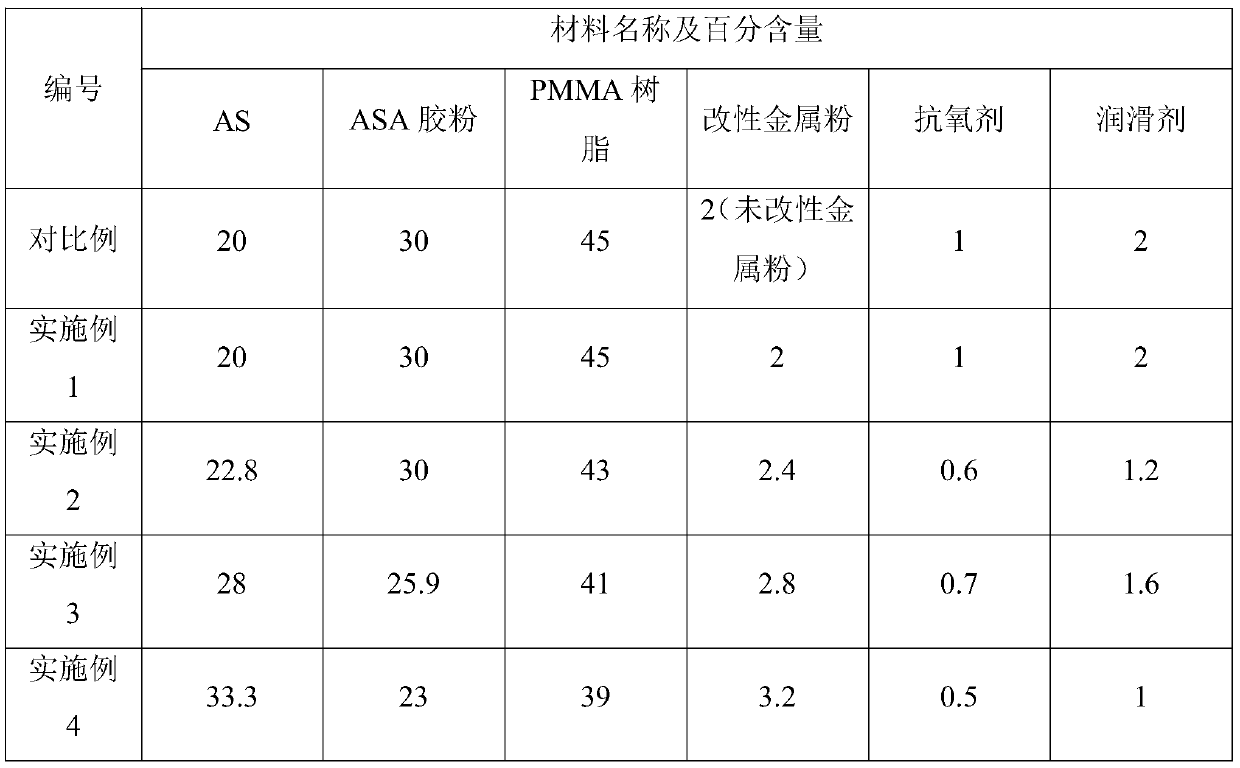

The invention relates to a high-light spray-free acrylonitrile-acrylate rubber-styrene terpolymer (ASA) / polymethyl methacrylate (PMMA) air-inlet grille special composite material and a preparation method thereof. The composite material consists of the following components in parts by weight: 20-40 parts of acrylonitrile-styrene (AS) resin, 35-45 parts of ASA high rubber powder, 35-45 parts of PMMAresin, 2-4 parts of modified metal powder, 0.5-1 part of an antioxidant and 1-2 parts of a lubricating agent. The composite material has the advantages that surface modification is carried out on themetal powder, so that the compatibility between the metal powder and the resin is improved, the overall fluidity of the material is improved, and flow marks formed in a material injection molding process can be effectively avoided while the comprehensive performance of the material is improved. According to the prepared high-light spray-free ASA / PMMA air-inlet grille special composite material, the excellent mechanical property, chemical oil resistance, weather resistance and processability of the ASA and PMMA materials are achieved, and the metallic texture is also achieved. Paint spraying treatment is not needed, so that the manufacturing efficiency of the automobile air-inlet grille is greatly improved, and the manufacturing cost is greatly reduced at the same time, so that the application prospect is very wide, and the composite material has a good economic value.

Owner:SHENZHEN FUHENG PLASTICS PIGMENT

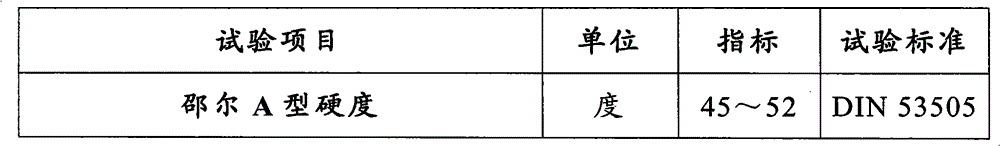

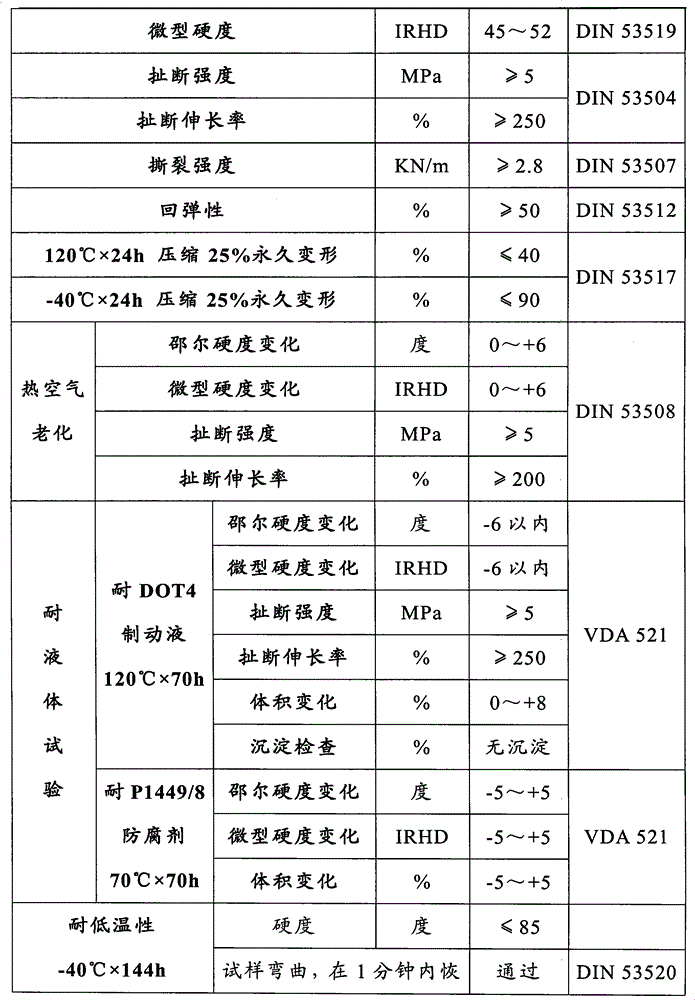

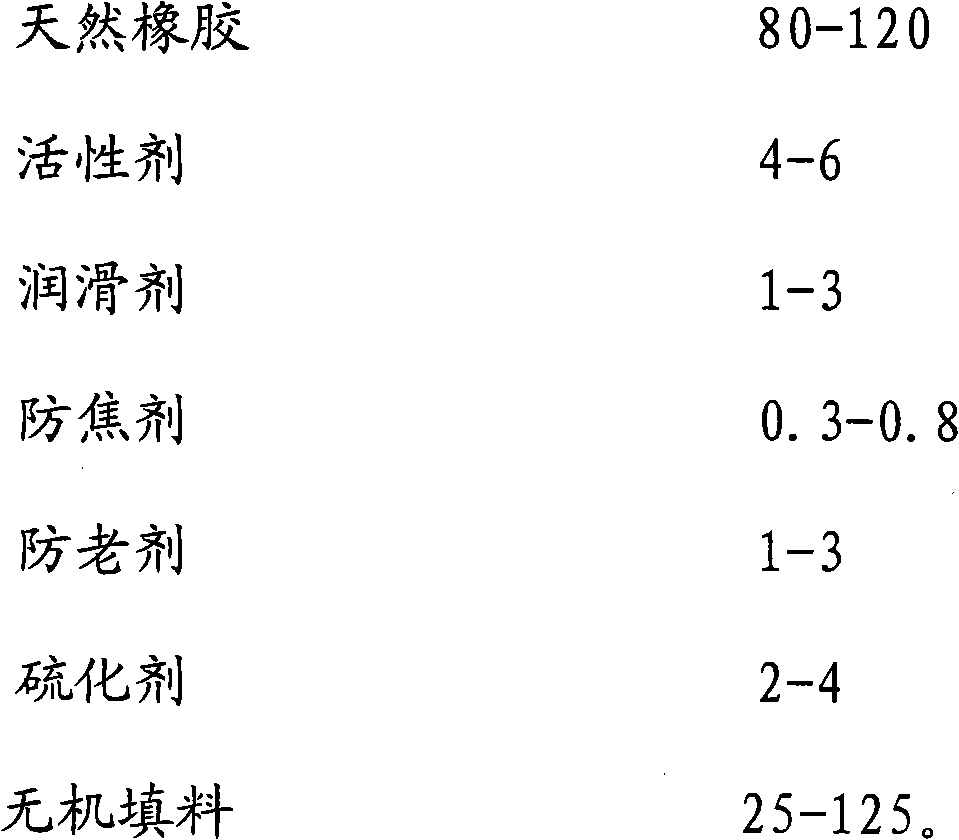

Oil inlet sealing ring material for vehicle brake master cylinder and process thereof for manufacturing sealing ring

The invention discloses an oil inlet sealing ring material for a vehicle brake master cylinder and a process thereof for manufacturing a sealing ring. The material is prepared from the following components in part by weight: 80 to 120 parts of ethylene propylene rubber, 4 to 6 parts of active agent, 1 to 3 parts of lubricant, 2 to 4 parts of acid-base balance agent, 1 to 3 parts of age resistor, 2 to 4 parts of sulfurizing agent and 25 to 35 parts of inorganic filler; then the components are subjected to the processes, namely mixing and molding, primary sulfurizing, punching and edge removingand secondary sulfurizing to obtain the oil inlet sealing ring material product with high strength, low compression deformation, tear resistance, resistance to braking fluid corrosion, resistance to low and high temperatures and excellent performance for the vehicle brake master cylinder; and the production efficiency and the product percent of pass are high, and the product can completely substitute similar imported products.

Owner:DATWYLER SEALING TECH ANHUI

Silica gel sponge material and preparation method thereof

The invention discloses a silica gel sponge material which comprises polyurethane sponge and a silica gel solution, and a functional auxiliary agent is added into the silica gel solution. The preparation method comprises the following steps: S1, designing the size and thickness of polyurethane sponge, the flowability of a silica gel solution and the proportion of a functional auxiliary agent according to product requirements; s2, according to design requirements, cutting the polyurethane sponge into sheets with corresponding thicknesses by using cutting equipment; s3, preparing a silica gel solution with corresponding flowability according to design requirements, and adding a functional auxiliary agent in a corresponding proportion into the silica gel solution; and S4, adding a silica gel solution on the polyurethane sponge sheet. According to the silica gel sponge material and the preparation method thereof, the silica gel solution is added on the polyurethane sponge, so that the polyurethane sponge has the effect of multiply increasing the tearing strength, meanwhile, the oxidation resistance and the high temperature resistance are improved, and the silica gel can also inhibit the generation of bacteria.

Owner:东莞市汇朋高分子科技有限公司

Big panel die of air conditioning cabinet and manufacturing method of big panel die of air conditioning cabinet

The invention discloses a big panel die of an air conditioning cabinet and a manufacturing method of the big panel die of the air conditioning cabinet. A die back panel is divided into three areas, each area is provided with an injection molding port, injection is firstly carried out from injection molding ports in two-side areas and then can be carried out from the injection molding port in the middle area, thus the pressure in the first area and the third area is always kept during an injection process, and the first area and the third area can be switched off when the second area has the pressure. A needed injection molding and mode locking pressure can be cut to be half of a theoretical value by cutting the needed injection molding and mode locking pressure, thus the material feed pressure is uniform, the internal stress is smaller, and the current ripple and the deformation on the surface can be avoided.

Owner:ANHUI ANLAN MOLD

Teflon spraying process

PendingCN112934632AFlat surfaceFull Coverage GuaranteedPretreated surfacesCoatingsPolymer scienceSurface cleaning

A Teflon spraying technology comprises the following steps that the viscosity of a coating is adjusted, and the viscosity of the coating used for first-time spraying needs to be high; the surfaces of parts are clean and free of stains; the coating is sprayed for the first time, spraying with the coating for the first time mainly guarantees the thickness of a paint film, and the thickness accounts for 90% or above; after coating, primary curing is carried out for 30 minutes in a drying oven at 220+ / -5 DEG C; the viscosity of the coating is adjusted, and the viscosity of the coating used for second-time spraying needs to be low; the coating is sprayed for the second time, spraying with the coating for the second time mainly guarantees the surface quality of the paint film, and the surface of a film layer is easily smooth by spraying with the coating with the lower viscosity; and after coating, secondary curing is carried out for 30 minutes in the drying oven at 220+ / -5 DEG C. According to the Teflon spraying process, two times of spraying are carried out; and during spraying, the first time of spraying adopts the coating with high viscosity, and the second time of spraying adopts the coating with low viscosity, so that the surface of the film layer is more uniform and smoother, meanwhile, the surface is completely covered, and flow marks are avoided.

Owner:AVIC GUIZHOU AIRPLANE

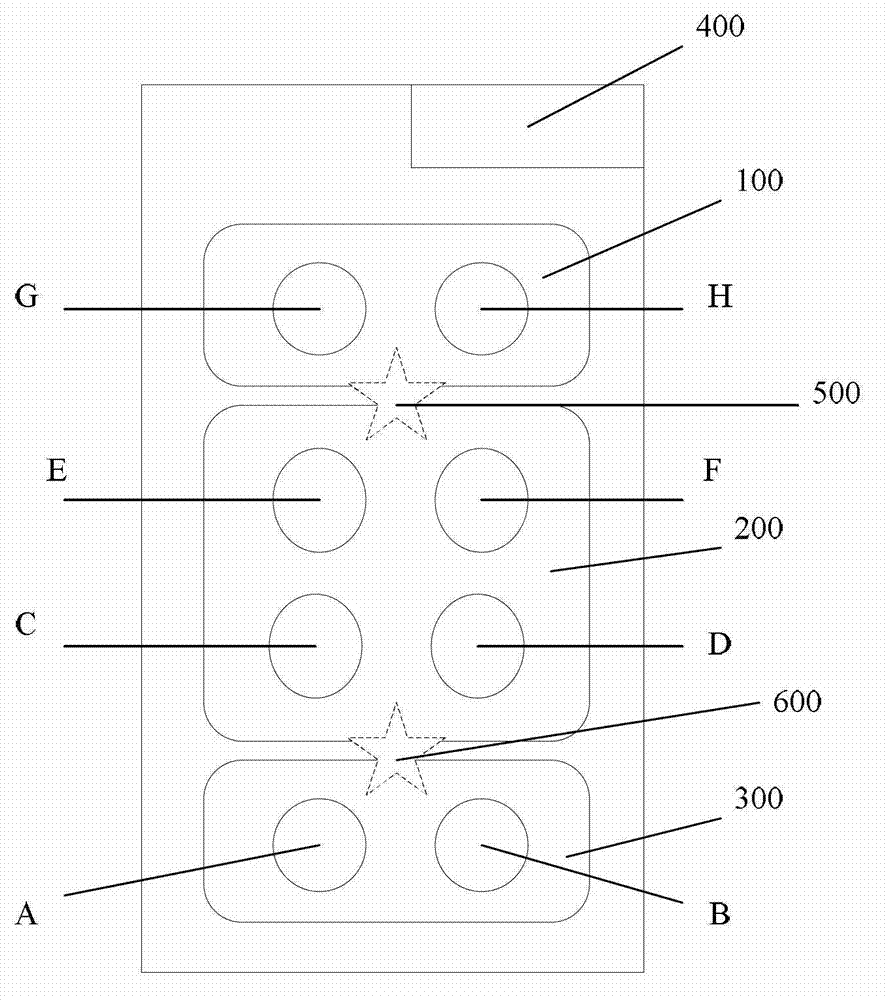

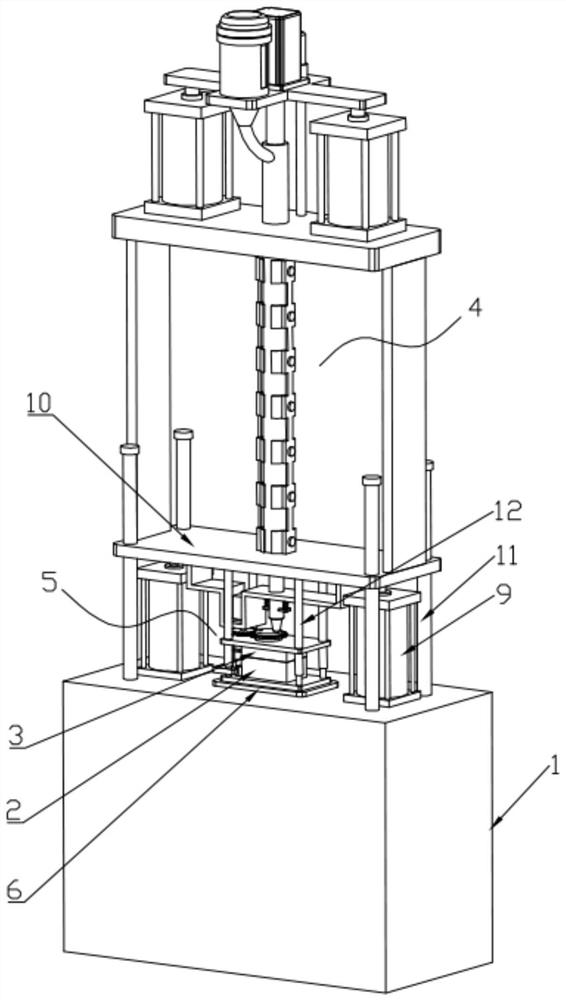

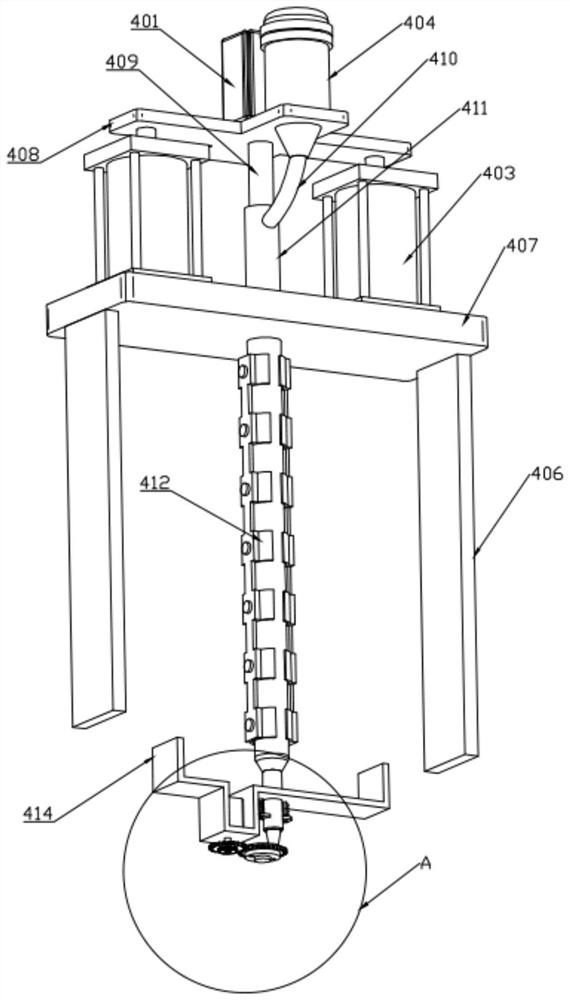

An injection molding device for plastic pipe clamps

ActiveCN111716630BThe melt flow state is consistentAvoid flow marksInjection molding processInjection moulding

The invention discloses an injection molding device for plastic pipe clips, relates to the technical field of injection molding equipment, and comprises a base, a lower injection mold, an upper injection mold, a filling mechanism and a demoulding mechanism. The invention realizes the change of the size of the gate by setting the filling mechanism, ensures that the flow state of the melt glue in the front and rear injection molding processes of the transition section remains consistent, and avoids the occurrence of flow marks; the injection molding process in which the gate size changes from small to large, flows through The melt in the runner will not maintain a high impact pressure all the time, which not only ensures the quality of the injection molding product, but also makes the mold have a longer service life, and can get rid of the air bubbles accumulated on the inner wall of the heating barrel to prevent Air enters the cavity and causes cavities inside or on the surface of the injection molded product; by setting a demoulding mechanism that cooperates with the filling mechanism, the adhesion to the mold is reduced, making it easier to demould, and the injection molded product will not be deformed Even damage the purpose.

Owner:芜湖富田电子科技有限公司

A casting coating for coated sand mold and preparation method thereof

ActiveCN107414016BDry fastReduce moisture contentFoundry mouldsFoundry coresSurface finishCarboxymethyl cellulose

Owner:保定保蒙新型材料科技有限公司

Metal casting mold capable of stabilizing internal air pressure based on high-end manufacturing

InactiveCN112475234ALarge and stable air pressureAir pressure fluctuationsFoundry mouldsFoundry coresAir springCasting mold

The invention relates to the technical field of casting and discloses a metal casting mold capable of stabilizing internal air pressure based on high-end manufacturing. The metal casting mold comprises a mold body; a bearing air plate is arranged in the mold body; an extrusion rod is fixedly connected to the top of the bearing air plate; a lever is rotatably connected to the top of the extrusion rod; a ventilation rod is rotatably connected to the right side of the lever; an air baffle is arranged at the bottom of the ventilation rod; an air blocking wheel is arranged above the bearing air plate; an extrusion air box is slidably connected to the side face of an extrusion air plate; an air spring is fixedly connected to the right side of the extrusion air box through a guide pipe; the rightside of the air spring is fixedly connected with a linkage rod; and the left side of the linkage rod is fixedly connected with an expansion plate. According to the metal casting mold capable of stabilizing the internal air pressure based on high-end manufacturing, through cooperative use of the extrusion rod and the bearing air plate, the effect of preventing fluctuation of the internal air pressure of the mold body during mold exhausting is achieved.

Owner:刘小羽

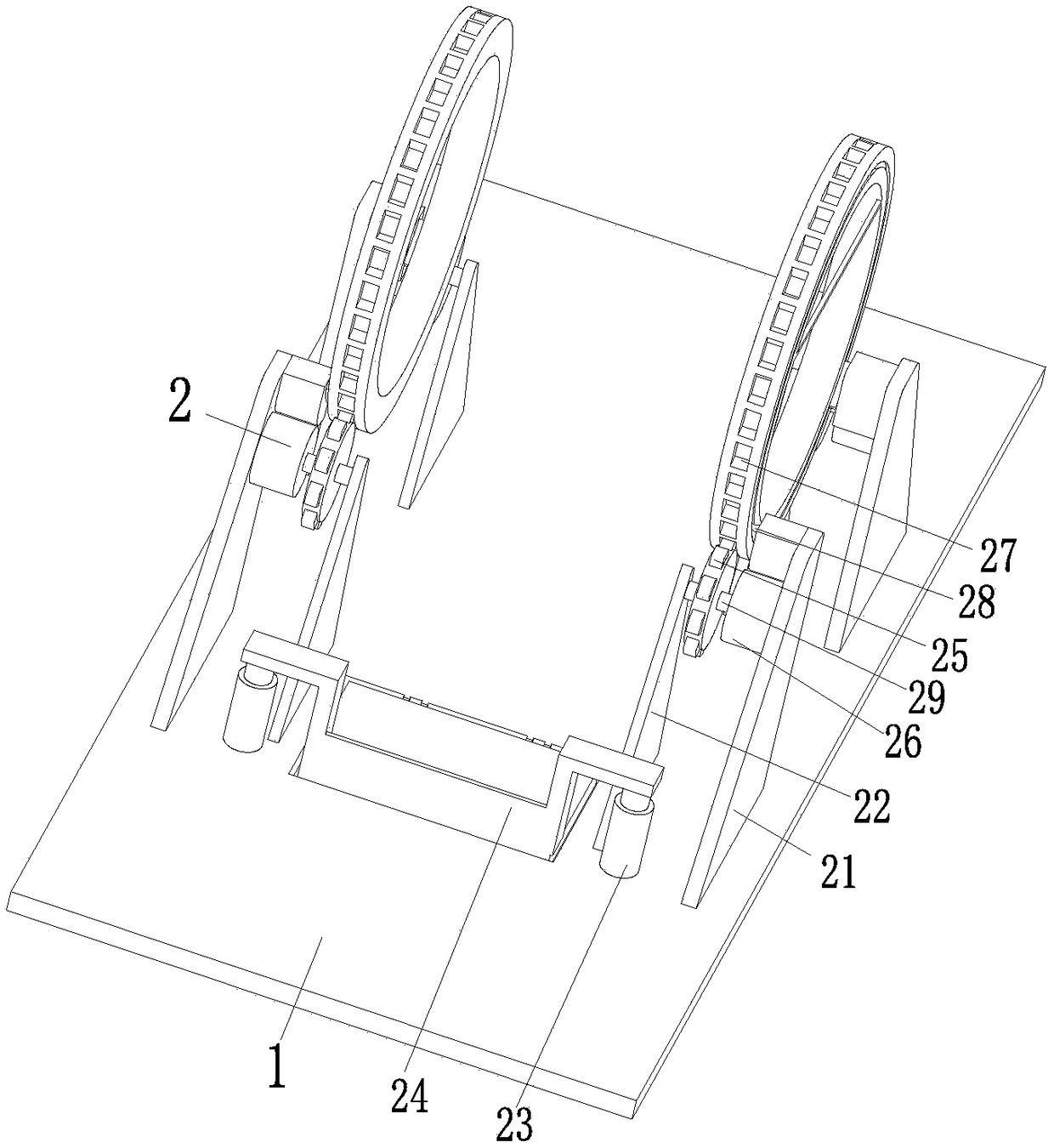

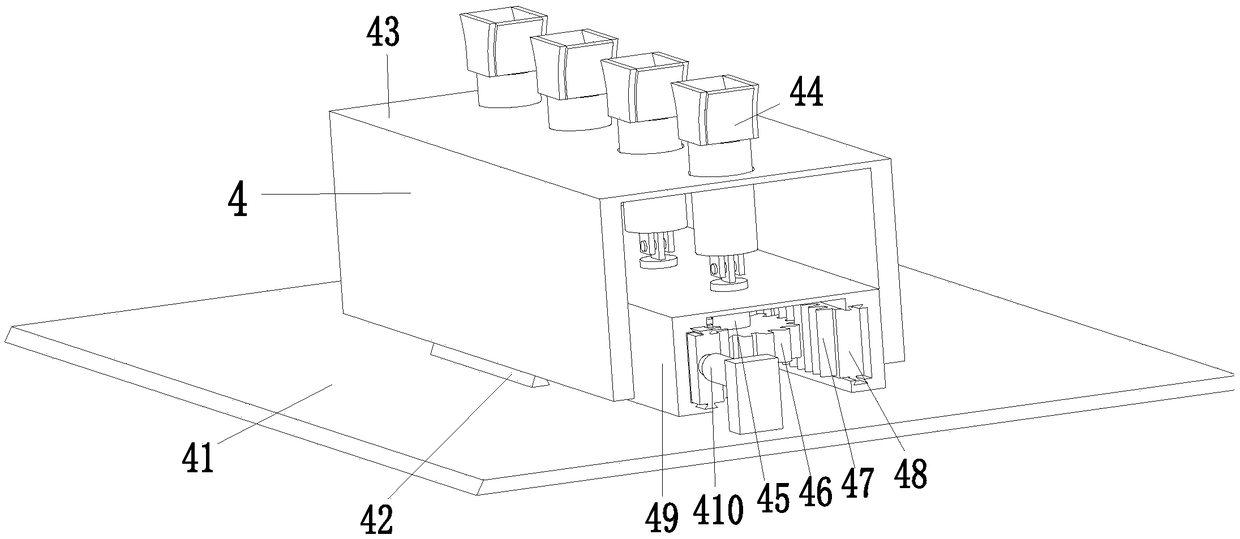

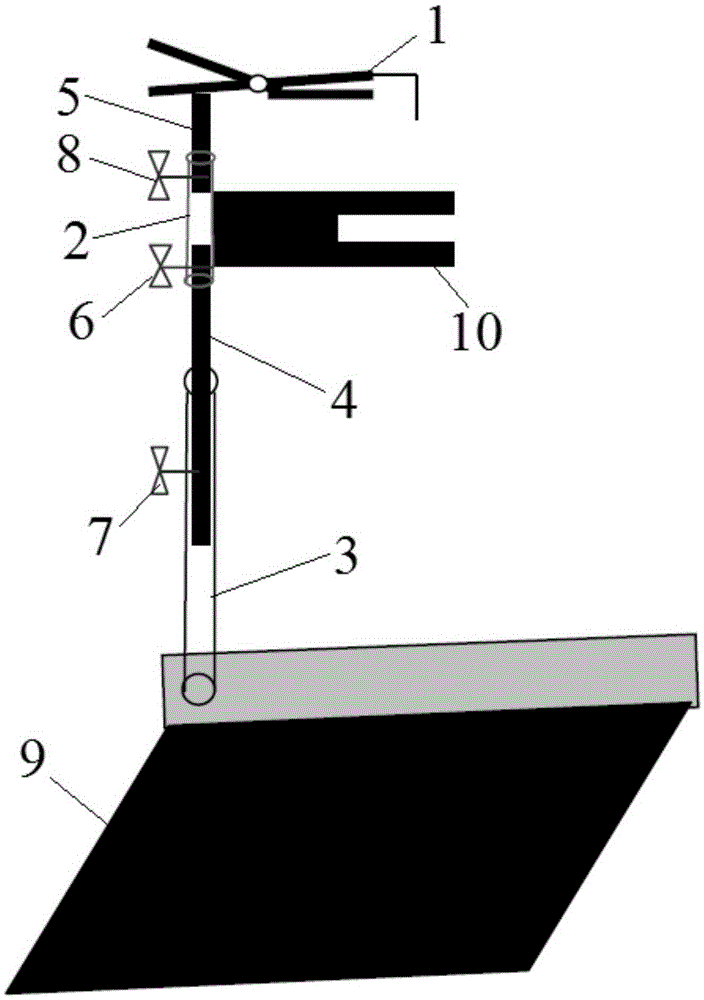

A kind of equipment for spraying casting coating on the surface of molding sand for sand casting

ActiveCN109014084BAvoid flow marksAvoid accumulationMoulding toolsSand castingMechanical engineering

The invention relates to equipment for spraying casting coating to the surface of molding sand for sand mould casting. The equipment comprises a bottom plate, a tumbling device and a coating device, ahole is formed in the middle portion of the front end of the bottom plate, the tumbling device is mounted on the upper end surface of the middle portion of the bottom plate, and the coating device isinstalled on the inner side face of the upper end of the tumbling device. The invention can solve the problems that an existing spraying machine cannot prevent flow marks and accumulation of coating,a nozzle cannot be rotated and tilted, the coating cannot cover the surface of a sand mould from all directions, and the spraying angle cannot be adjusted at will; and the function of automatically spraying the casting coating to the surface of the molding sand can be realized.

Owner:微山县汉润机械制造有限公司

Polyamide material with metallic texture and preparation method thereof

The invention provides a polyamide material and a preparation method thereof. The polyamide material with core-shell structure metal toner without spraying is prepared from the following raw materials: low-viscosity polyamide 6 resin, high-viscosity polyamide 6 low-resin, anti- Oxygen agent, lubricant, heat-resistant oxygen aging agent, metal toner with core-shell structure. The spray-free polyamide material prepared by the core-shell structure metal toner has excellent mechanical properties and processing properties, and can be applied to the fields of automobiles and home appliances such as automobile exterior decoration, air-conditioning decorative strips, and exterior decoration structures of small household appliances.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

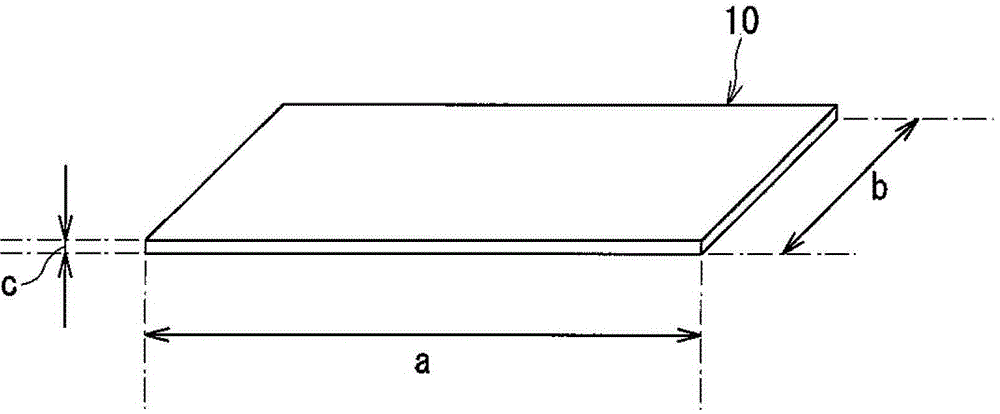

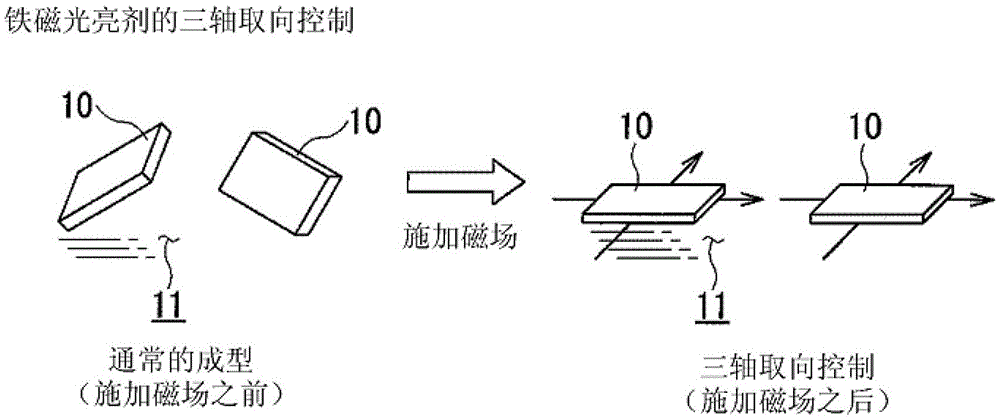

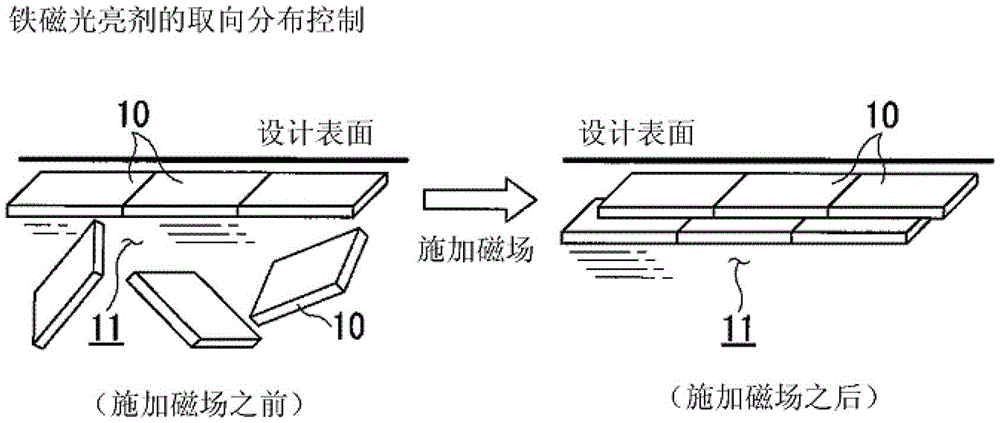

Resin molded body and method for producing the same

InactiveCN103421339BGood metal textureGood lookingOrganic/organic-metallic materials magnetismArtistic surface treatmentElastomerDistribution control

A resin molded body comprising a polymeric material such as one of thermoplastic resin, thermosetting resin, elastomer and rubber added with a desired amount of ferromagnetic brightener having shape anisotropy and a method for producing the same. When the polymer material is in the state of molten resin inside the mold cavity, the polymer material is subjected to three-axis orientation control and orientation distribution control. Orientation of the ferromagnetic brightener in the resin, and displacing the ferromagnetic brightener mixed in the molten resin in a desired direction, by which the ferromagnetic brightener mixed in the molten resin is displaced to the design surface side, The orientation is distributed intensively, and the molding process is carried out by this.

Owner:SUZUKI MOTOR CORP

Inner cavity spraying method of small-diameter long-axis parts

InactiveCN106341990BAchieve sprayingAvoid flow marksLiquid surface applicatorsCoatingsLongest DiameterLong axis

The invention is an inner chamber spraying technology of small-diameter and long-axis parts, which uses a long spray gun rod to realize the spraying of long-diameter inner chamber parts; at the same time, it adopts the method of rotating the parts and automatically feeding the spray gun during the spraying process, During the spraying process, the movement track of the spray gun coincides with the rotation axis of the part, which ensures the uniform coating of the inner cavity of the part, avoids other uneven phenomena such as flow marks or missing coatings in the inner cavity paint layer of the part after spraying, and controls the spraying The static balance change value of the front and rear parts is within 300g.mm, which can be widely used for the inner cavity spraying of small diameter and long shaft parts.

Owner:HARBIN DONGAN ENGINE GRP

Rubber spring material for automobile braking double-cavity serial brake valve and preparation method thereof

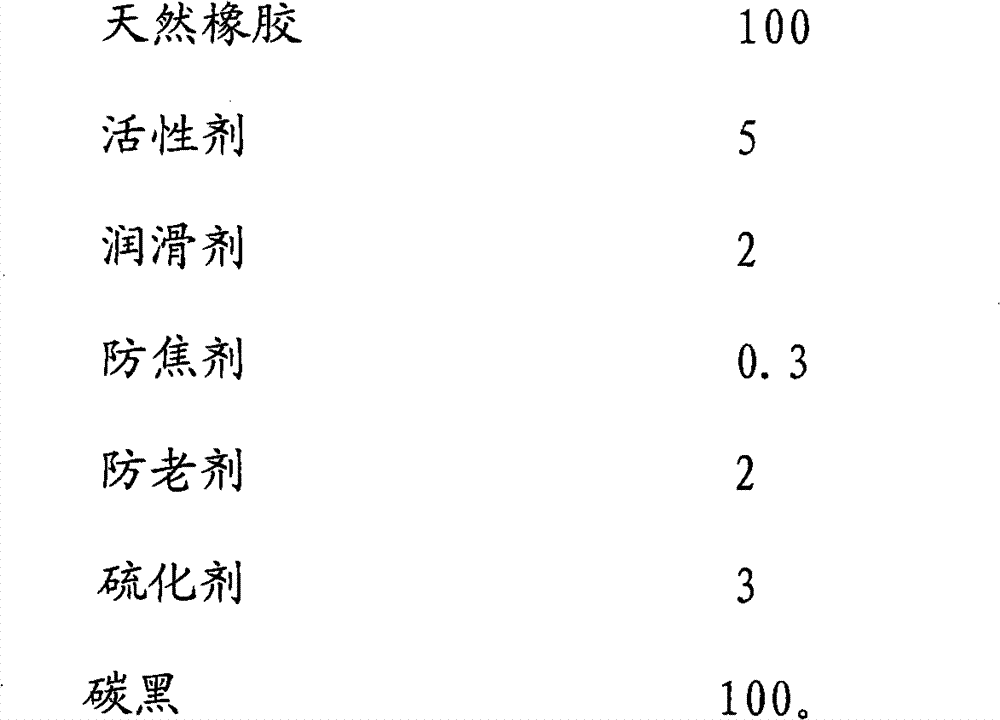

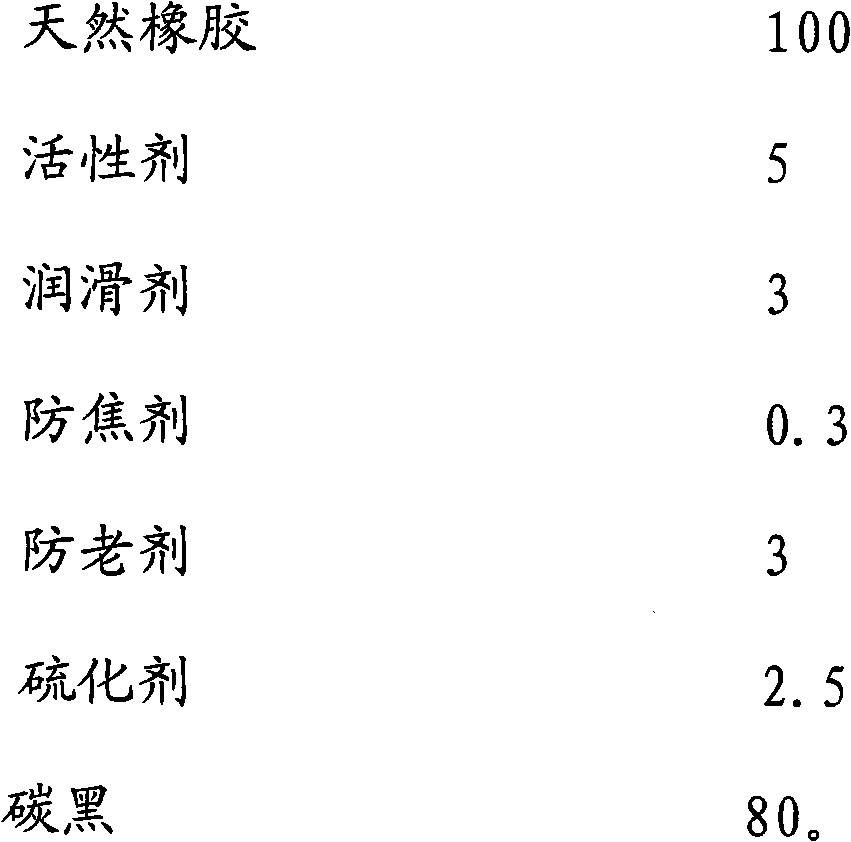

The invention discloses a rubber spring material for an automobile braking double-cavity serial brake valve and a preparation method thereof. The rubber spring material comprises the following raw materials in parts by weight: 80 to 120 parts of natural rubber, 4 to 6 parts of activating agent, 1 to 3 parts of lubricating agent, 0.3 to 0.8 part of antiscorching agent, 2 to 4 parts of vulcanizing agent and 75 to 125 parts of carbon black. The preparation method comprises the following steps of: performing hybrid forming on the raw materials; vulcanizing; removing edges through punching; and detecting. The prepared rubber spring material for the automobile braking double-cavity serial brake valve has the advantages of high strength, tear resistance, low compressive deformation, brake fluid resistance and superior aging resistance; qualification rate and production efficiency of a product can be guaranteed by using a vulcanization molding process; and a domestication process of high-end automobile parts is accelerated.

Owner:DATWYLER SEALING TECH ANHUI

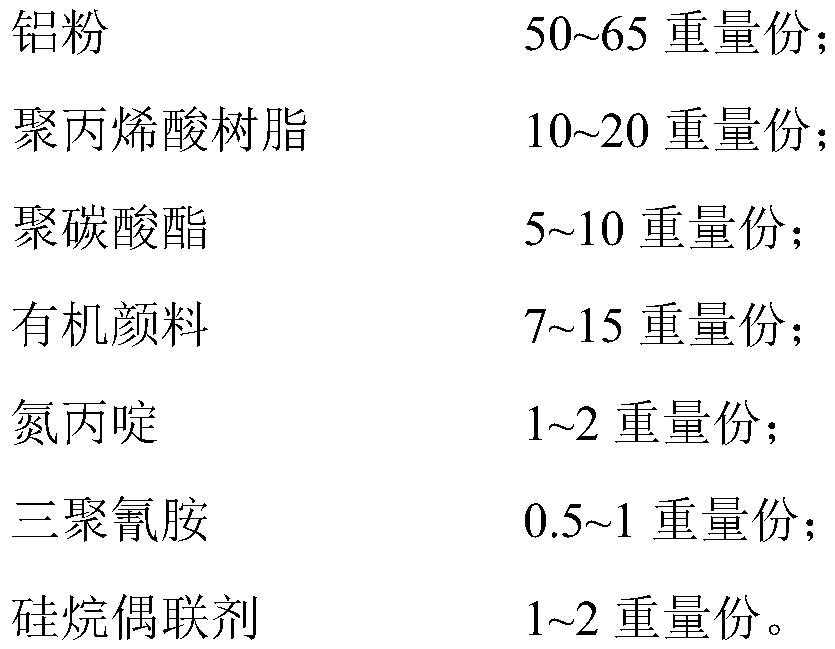

Spraying-free colored aluminum pigment and preparation method thereof

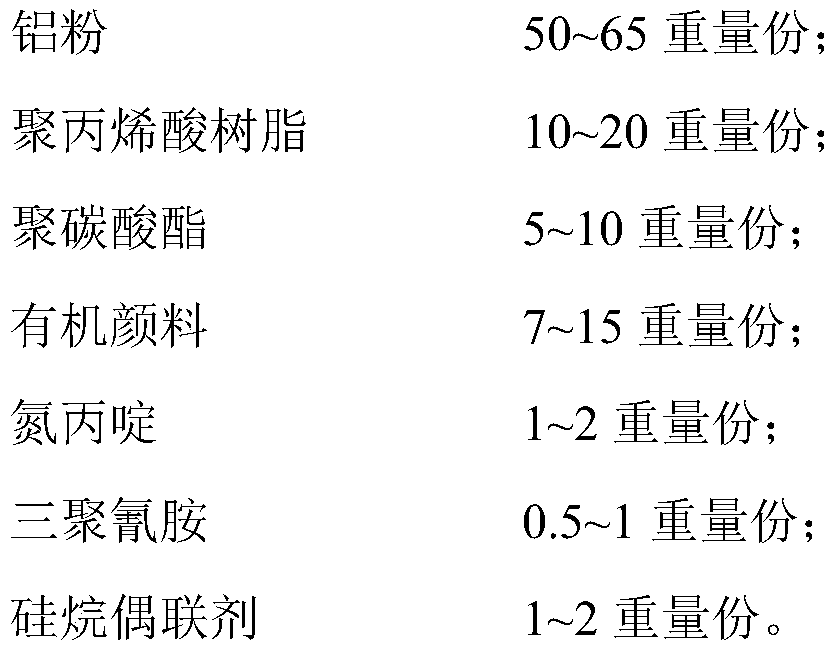

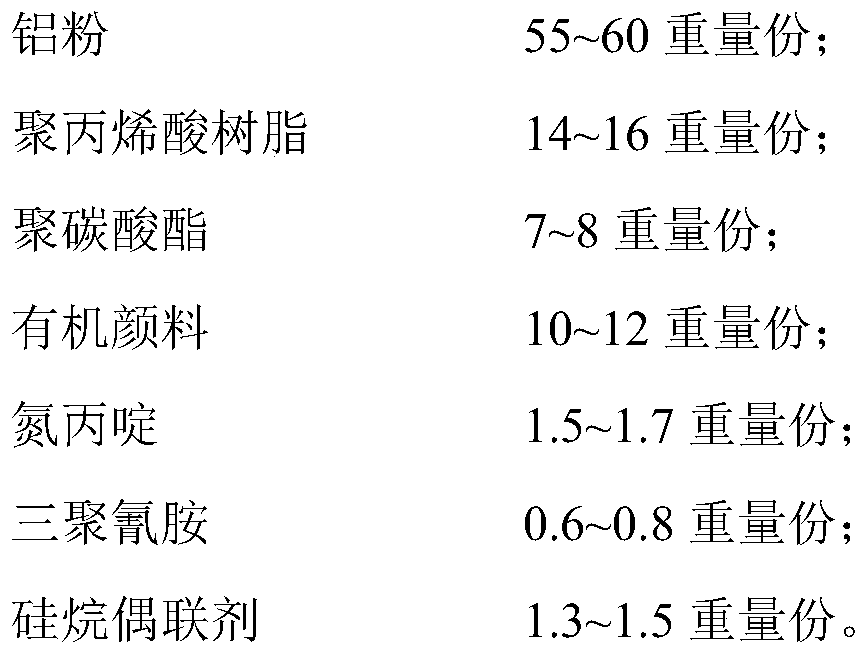

The invention discloses a spraying-free colored aluminum pigment and a preparation method thereof. The spraying-free colored aluminum pigment comprises the following components by weight: 50-65 partsof aluminum powder; 10-20 parts of polyacrylic resin; 5-10 parts of polycarbonate; 7-15 parts of an organic pigment; 1-2 parts of aziridine; 0.5-1 part of melamine; and 1-2 parts of a silane couplingagent. The spraying-free colored aluminum pigment has very excellent dispersity and fluidity when subjected to melt injection molding after being mixed with resin, so that the surface color of an obtained colored resin product is bright and uniform, small in brightness deviation and excellent in metal appearance, and flow marks and weld lines can be avoided. The preparation method of the spraying-free colored aluminum pigment provided by the invention is simple and practical, and low in implementation cost.

Owner:广东麒麟精工科技有限公司

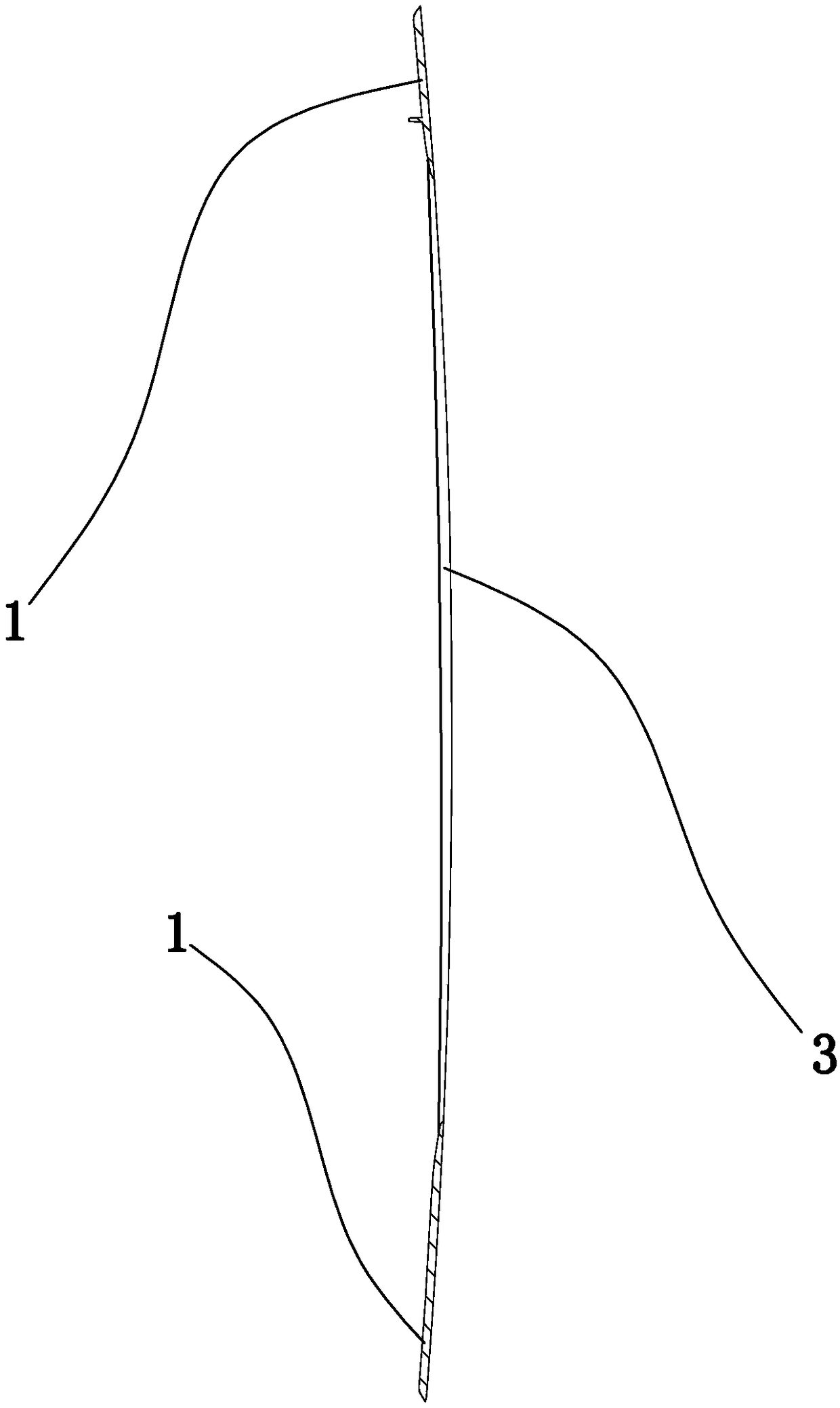

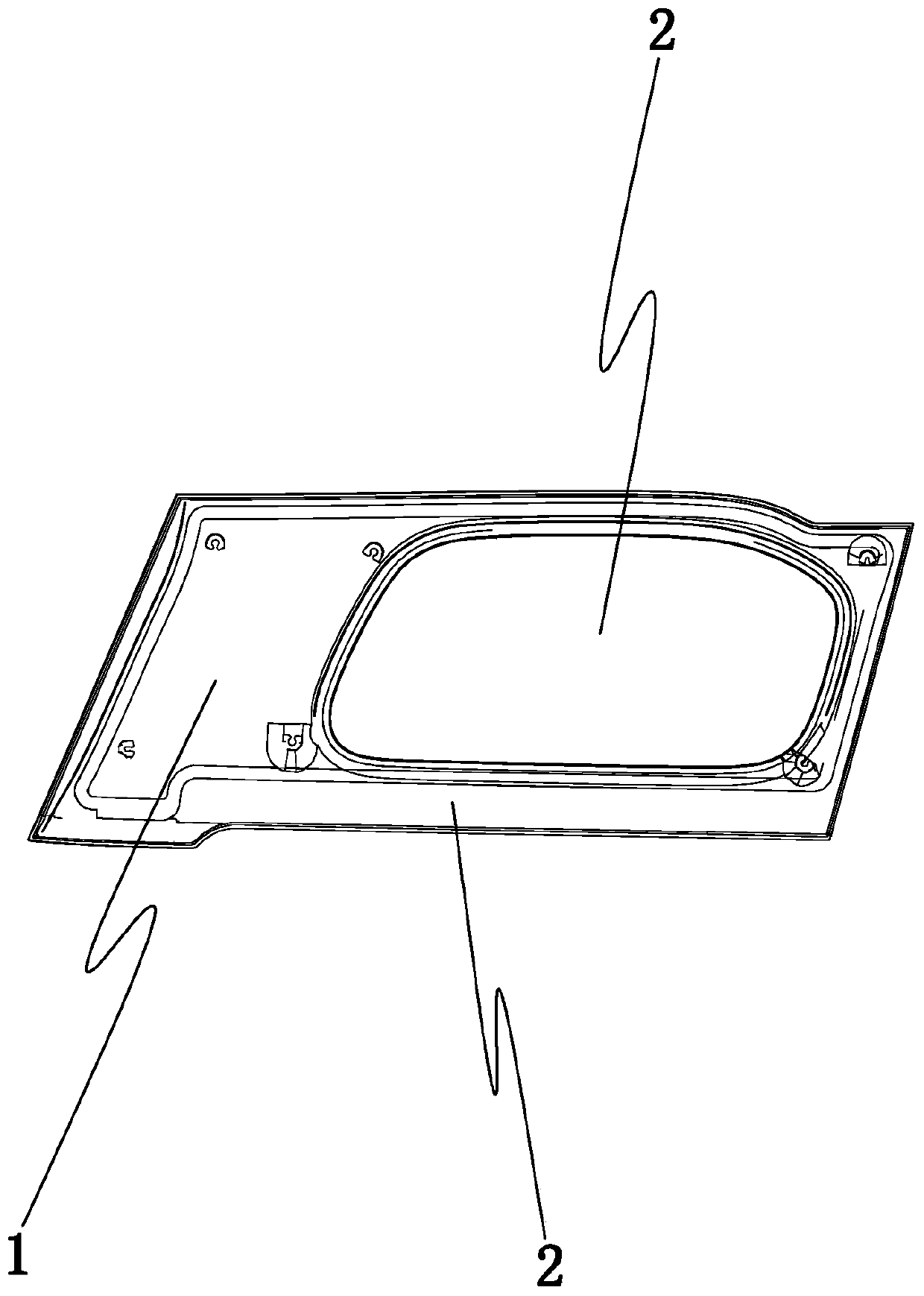

Automatic liquid-blocking type plastic glass and curtain-coating method

ActiveCN108297510APrevent flowAvoid strandedLamination ancillary operationsSynthetic resin layered productsEngineeringBlack edge

The invention discloses an automatic liquid-blocking type plastic glass, which comprises a black edge layer and a transparent layer. The black edge layer is connected to the transparent layer. The black edge layer is provided with a curtain-coating baffling rib. The black edge layer is arranged between the curtain-coating baffling rib and the transparent layer. The black edge layer is provided with a through hole. One end of the through hole is an external opening end, the other end of the through hole is an internal opening end, and the transparent layer seals the internal opening end. The structure is reasonable; during the process of front curtain-coating, the curtain-coating liquid is prevented from flowing to the back surface, the flowing mark on the appearance after thermosetting isavoided, the surface quality of the transparent layer is guaranteed; the curtain coating liquid will not stay on the interface between the external edge of the black edge layer and the transparent layer, thus the moulding effect is ensured, and the performance and appearance are both qualified.

Owner:SHENTONG TECH GRP CO LTD

A structure to prevent the rubber in the gate from breaking in the mold

ActiveCN106182624BSolve the problem remaining in the gate forming partExtended service lifeEngineeringMechanical engineering

Owner:WUHAN LIAOYUAN MOLDING

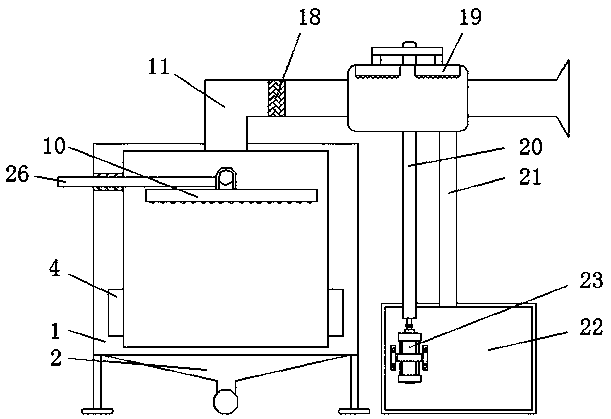

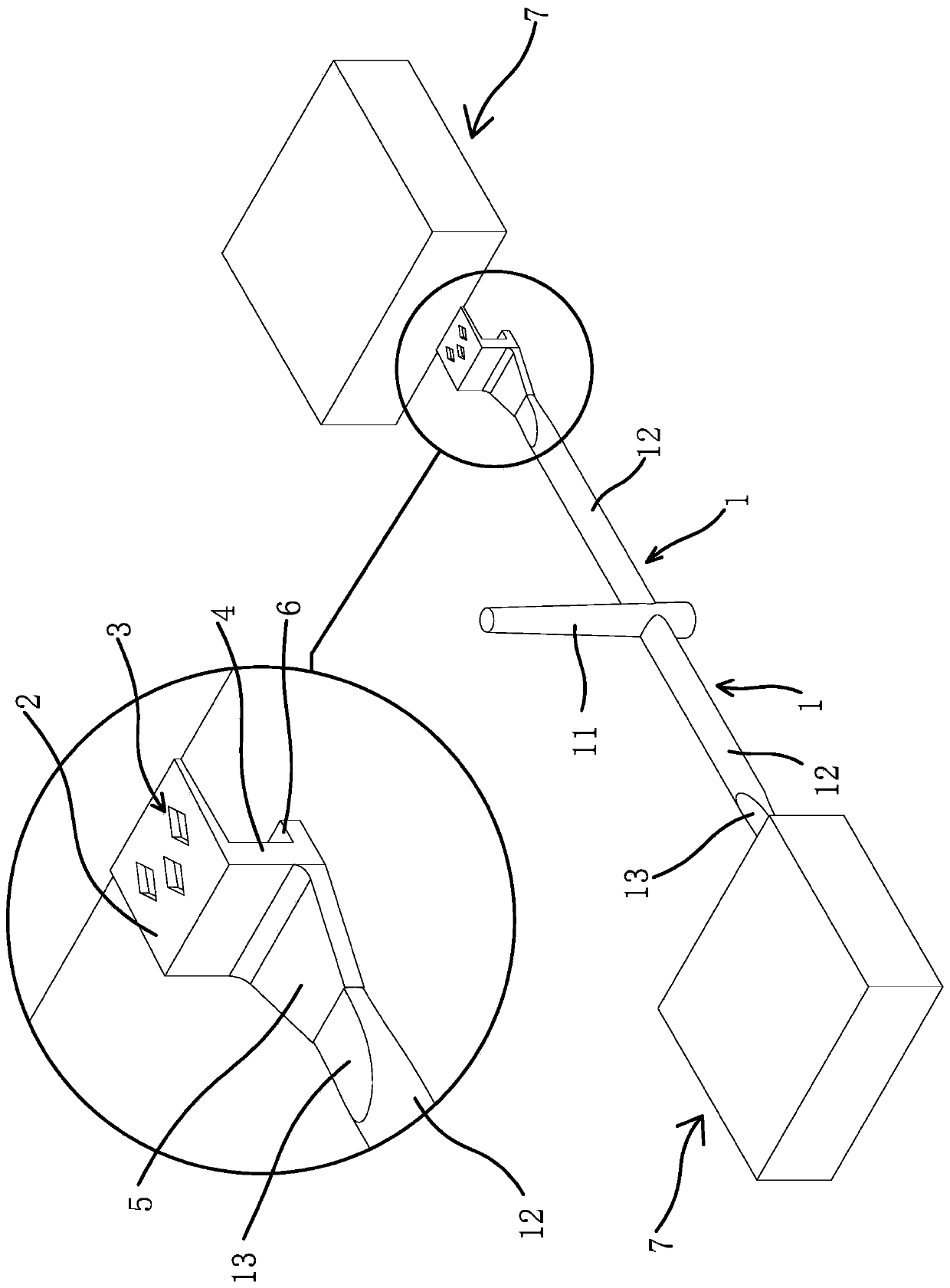

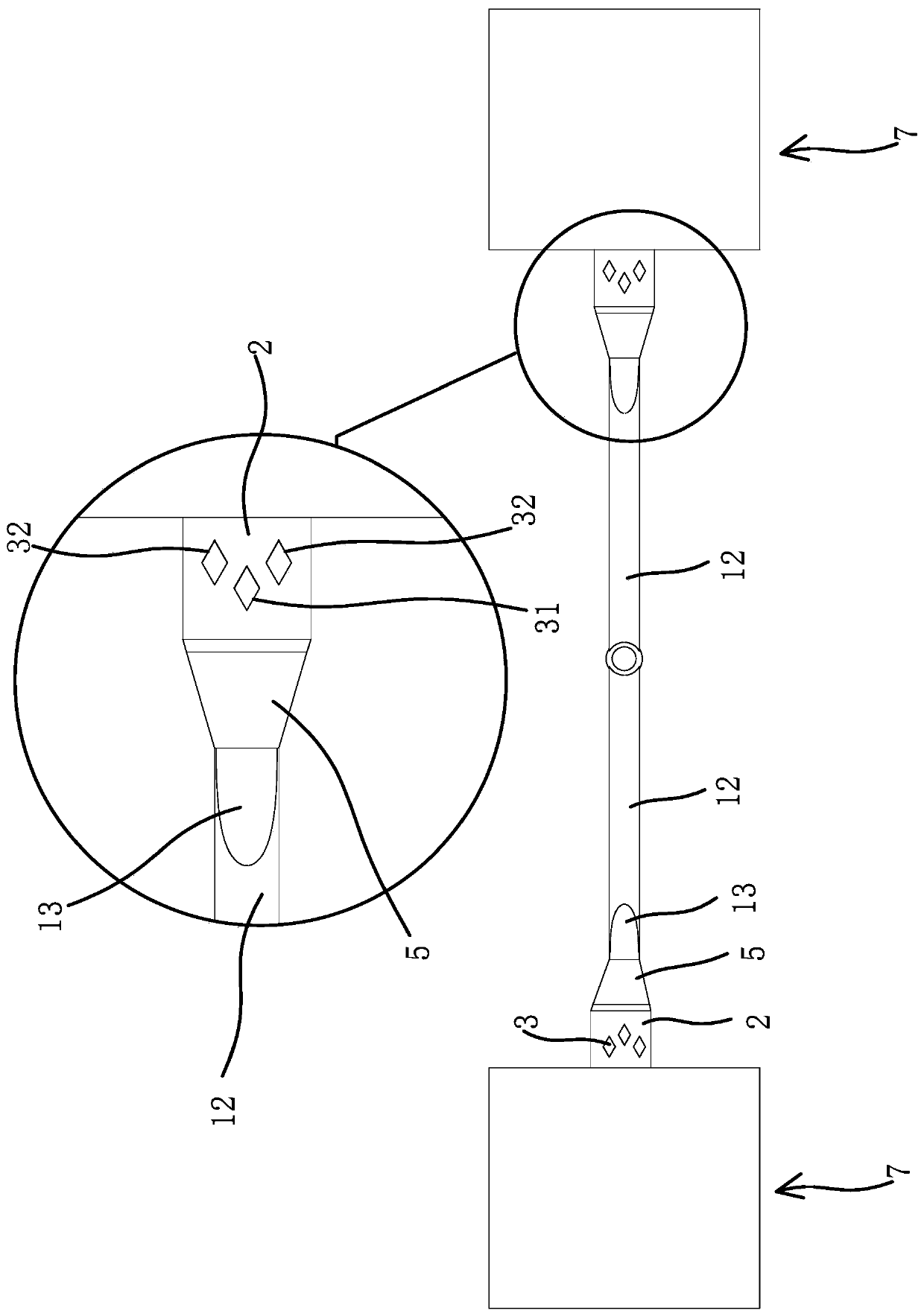

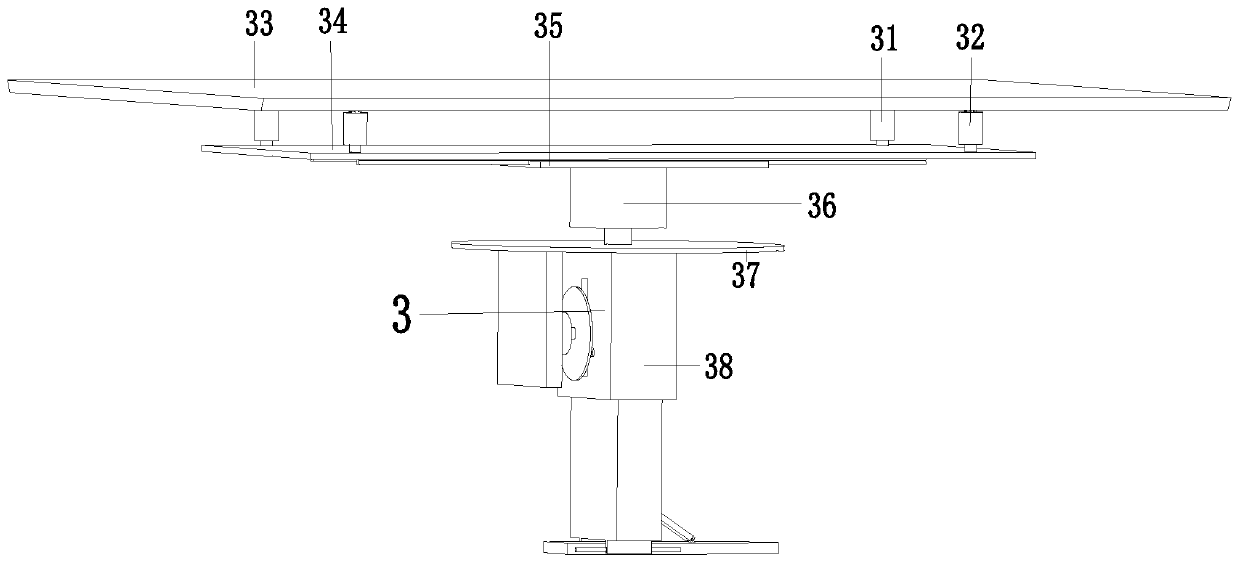

A casting molding sand surface automatic spraying system and molding sand surface spraying process

The invention relates to an automatic cast molding sand surface spraying system. The automatic cast molding sand surface spraying system comprises a bottom plate, a rolling device, a compaction deviceand a coating device. A hole is formed in the middle portion of the front end of the bottom plate. The rolling device is arranged on the upper end face of the middle portion of the bottom plate. Thecompaction device is arranged on the inner side face of the lower end of the rolling device. The coating device is arranged on the inner side face of the upper end of the rolling device. The automaticcast molding sand surface spraying system can solve the problems that according to an existing spraying machine, flow marks and stacking of coatings cannot be prevented, a sprayer cannot rotate or incline, the coatings cannot comprehensively cover the surface of a sand mould, the spraying angle cannot be adjusted at will, and secondary compaction cannot be conducted on the surface of molding sand; and the function of automatic spraying of the casting coatings to the surface of the molding sand can be achieved.

Owner:安徽合鑫机械设备制造有限公司

A smokeless polishing solution for aluminum

ActiveCN107177848BIncrease brightnessOvercoming the problem of producing toxic nitrogen oxidesSulfatePhosphoric acid

The invention discloses a smokeless polishing solution for aluminum products. The smokeless polishing solution is prepared from, by weight, 50%-65% of phosphoric acid, 15%-20% of sulfuric acid, 1%-3% of aluminum salt, 10%-15% of water and 3%-10% of additives. The additives comprise, by weight, 15%-20% of sorbitol, 8%-12% of sodium dodecyl benzene sulfonate, 2%-6% of polyethylene glycol, 8%-10% of sodium tripolyphosphate, 3%-8% of cupric sulfate pentahydrate and 48%-55% of water. By adopting the smokeless polishing solution, the polishing effect of a traditional three-acid polishing solution can be basically achieved, no yellow smoke is generated, and no flow mark is generated when drip hanging is conducted for a long time.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

An automatic liquid-shielding plastic glass and its spray coating method

ActiveCN108297510BPrevent flowAvoid strandedLamination ancillary operationsSynthetic resin layered productsSpray coatingMechanical engineering

The invention discloses an automatic liquid-blocking type plastic glass, which comprises a black edge layer and a transparent layer. The black edge layer is connected to the transparent layer. The black edge layer is provided with a curtain-coating baffling rib. The black edge layer is arranged between the curtain-coating baffling rib and the transparent layer. The black edge layer is provided with a through hole. One end of the through hole is an external opening end, the other end of the through hole is an internal opening end, and the transparent layer seals the internal opening end. The structure is reasonable; during the process of front curtain-coating, the curtain-coating liquid is prevented from flowing to the back surface, the flowing mark on the appearance after thermosetting isavoided, the surface quality of the transparent layer is guaranteed; the curtain coating liquid will not stay on the interface between the external edge of the black edge layer and the transparent layer, thus the moulding effect is ensured, and the performance and appearance are both qualified.

Owner:SHENTONG TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com