Spraying-free effect pigment as well as preparation method and application thereof

An effect pigment and spray-free technology, which is applied in the field of spray-free effect pigments and its preparation, can solve the problems of affecting the appearance effect, easy to flip, difficult orientation flip, etc., achieve a good spray-free metal effect, and avoid weld marks and flow marks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

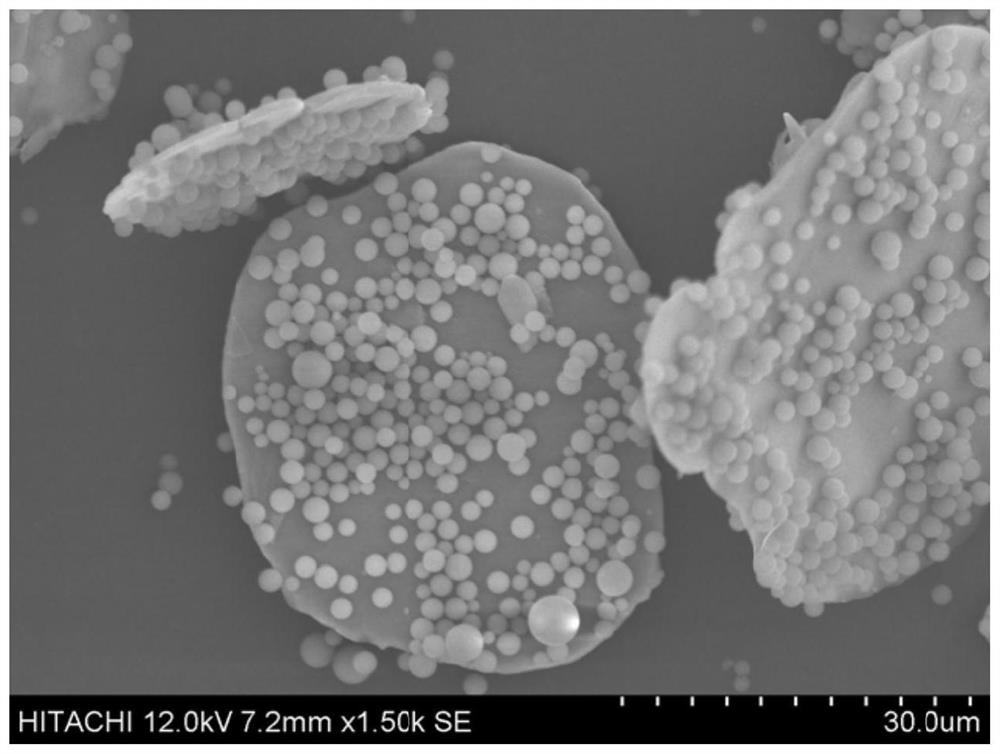

Image

Examples

Embodiment 1~16

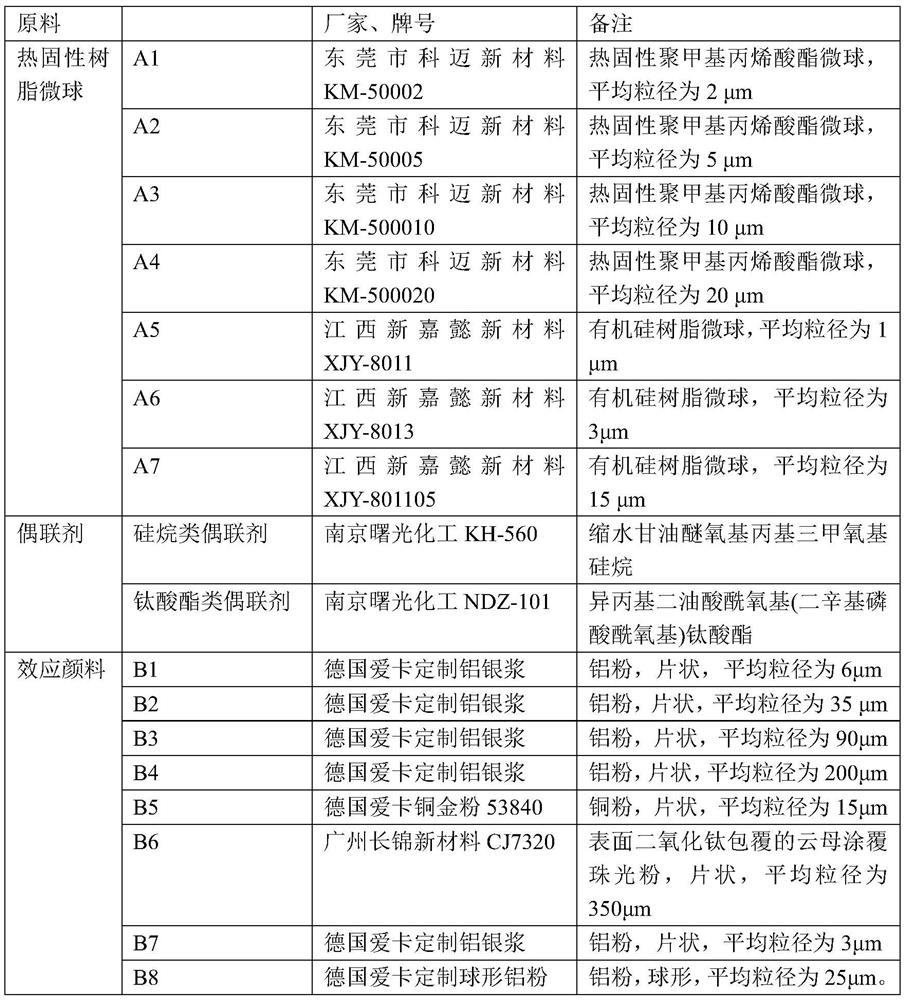

[0055] Embodiments 1 to 16 respectively provide a spray-free effect pigment, the component content is shown in Table 1, and the preparation method is as follows:

[0056] At 30°C, the effect pigment and thermosetting resin were dispersed in an organic solvent (ethanol, commercially available) dissolved with a coupling agent, and after stirring for 5 hours, the organic solvent was removed by heating to obtain a spray-free effect pigment.

[0057] Table 1 Component content (parts by weight) of the spray-free effect pigments of Examples 1-16

[0058]

[0059]

Embodiment 17~34

[0061] Embodiments 17 to 34 respectively provide a spray-free material, the component contents are shown in Table 2, and the preparation method is as follows:

[0062]The thermoplastic resin is added to the main feeding port of the twin-screw extruder, the spray-free effect pigment is added to the side feeding port of the twin-screw extruder, and the spray-free material is obtained by melt mixing, extrusion and granulation; The outlet temperature is 170~320℃, and the screw speed is 350~450rpm.

[0063] Table 2 Component content (parts by weight) of the spray-free materials of Examples 17-34

[0064]

[0065]

Embodiment 17

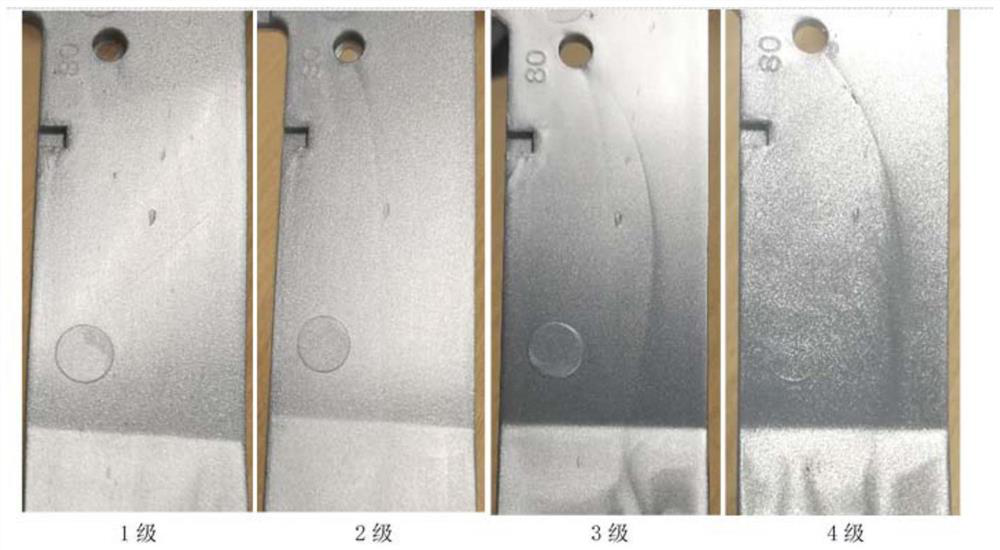

[0088] In Examples 17-28, the comprehensive appearance effect index (I) of the spray-free materials of Examples 18, 19, 22, 23, 25, 27, and 28 was relatively higher, and the spray-free effect was better; followed by Example 17, Again Examples 20, 21, and again Examples 24, 26. It can be seen that the ratio of the average particle size of the thermosetting resin microspheres to the effect pigment is different, and the average particle size of the effect pigment is different, which affects the spray-free appearance effect of the material. The ratio of the average particle size of the thermosetting resin microspheres to the effect pigment is preferably 1:(6-30).

[0089] According to Examples 17, 30, 31, and 32 combined with Examples 1, 14, 15, and 16, the spray-free appearance effect index of Examples 31 and 32 is slightly worse. Therefore, the component content of spray-free effect pigments is preferably: effect pigments 100 parts, 20-50 parts of coupling agent, 30-100 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com