Spraying-free colored aluminum pigment and preparation method thereof

A spray-free, aluminum pigment technology, applied in the chemical industry, can solve the problems of surface brightness and color distribution unevenness, dispersibility, poor fluidity, and discounted metallic sensory effects, etc., to achieve excellent and excellent metallic sensory Metallic luster effect, colorful surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

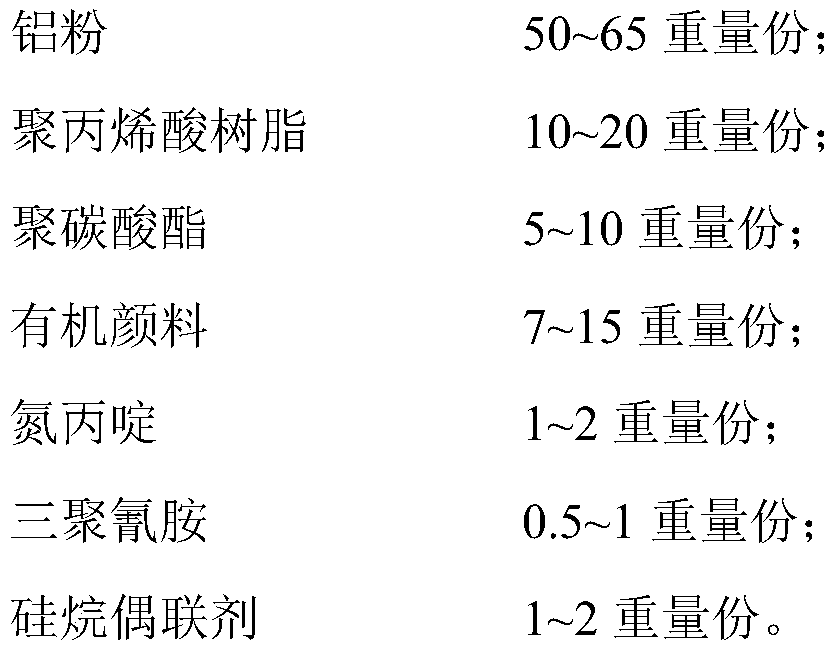

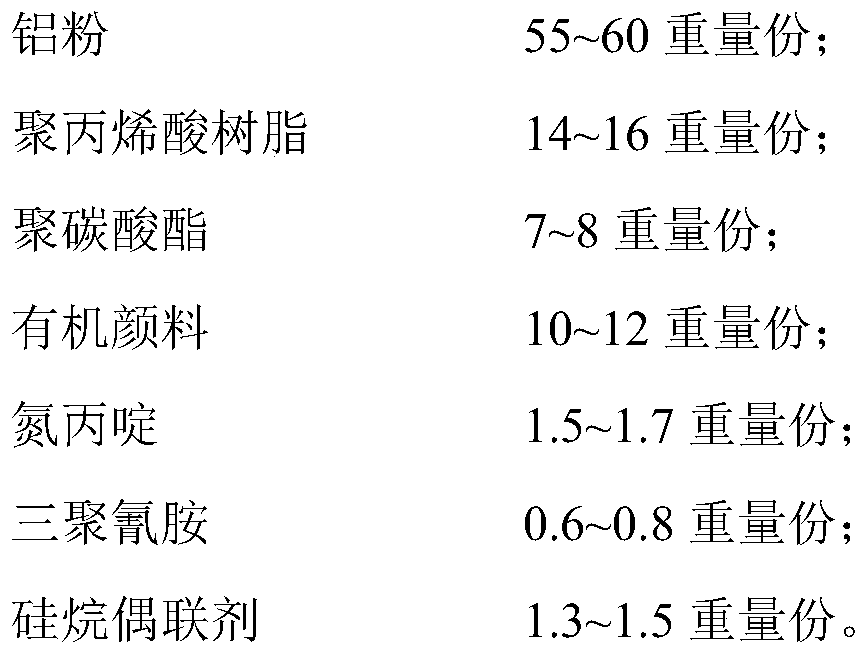

Method used

Image

Examples

Embodiment 1

[0058] Adopt following preparation method to prepare according to the spray-free colored aluminum pigment of the present invention:

[0059] (1) Put 57kg of aluminum powder, 15kg of polyhydroxyethyl acrylate, 7.5kg of bisphenol A polycarbonate and 0.7kg of melamine into a rotary internal mixer, at a temperature of 230°C with 20r / Min speed kneading for 20 minutes;

[0060] (2) Add 1.6kg of aziridine and 1.4kg of (3-aminopropyl)trimethoxysilane to the resultant of step (1), and knead at a rate of 12r / min at a temperature of 200°C 30 minutes; and

[0061] (3) Add 10kg of Pigment Blue 15:3 to the product of step (2), and knead at a temperature of 190° C. at a rate of 8 r / min for 20 minutes.

[0062] (4) The product obtained in step (3) is made into a powder with a particle size of 10-50 μm, thereby preparing the spray-free colored aluminum pigment according to the present invention.

Embodiment 2

[0064] Adopt following preparation method to prepare according to the spray-free colored aluminum pigment of the present invention:

[0065] (1) Put 55kg of aluminum powder, 16kg of polyhydroxyethyl acrylate, 7kg of bisphenol A polycarbonate and 0.8kg of melamine into an overturning mixer, at a temperature of 220°C at 22r / min kneading at the speed of 18 minutes;

[0066] (2) Add 1.5 kg of aziridine and 1.5 kg of (3-aminopropyl) trimethoxysilane to the resultant of step (1), and knead at a rate of 13 r / min at a temperature of 190° C. 25 minutes; and

[0067] (3) Add 10 kg of Pigment Blue 15:3 to the product of step (2), and knead at a temperature of 200° C. at a rate of 10 r / min for 17 minutes.

[0068] (4) The product obtained in step (3) is made into a powder with a particle size of 10-50 μm, thereby preparing the spray-free colored aluminum pigment according to the present invention.

Embodiment 3

[0070] Adopt following preparation method to prepare according to the spray-free colored aluminum pigment of the present invention:

[0071] (1) Put 60kg of aluminum powder, 14kg of polyhydroxyethyl acrylate, 8kg of bisphenol A polycarbonate and 0.6kg of melamine into an overturning mixer, at a temperature of 220°C at 17r / min kneading at the speed of 15 minutes;

[0072] (2) Add 1.7kg of aziridine and 1.3kg of (3-aminopropyl)trimethoxysilane to the resultant of step (1), and knead at a rate of 13r / min at a temperature of 200°C 27 minutes; and

[0073] (3) Add 10kg of Pigment Blue 15:3 to the product of step (2), and knead at a temperature of 180° C. at a rate of 9 r / min for 22 minutes.

[0074] (4) The product obtained in step (3) is made into a powder with a particle size of 10-50 μm, thereby preparing the spray-free colored aluminum pigment according to the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com