Manufacturing method of plastic lens

一种塑料透镜、制造方法的技术,应用在其他家里用具、光学元件、家里用具等方向,达到防止熔接痕的产生的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0047] First, the first embodiment of the present invention will be described. The shape of the plastic lens to be molded in this embodiment is not particularly limited. The present invention can also be applied to a method of forming a semi-finished lens in a semi-finished state thicker than the finished size in advance, and finishing the semi-finished product called a "semi-finished lens" into a final shape by post-processing.

[0048] 【Injection molding equipment】

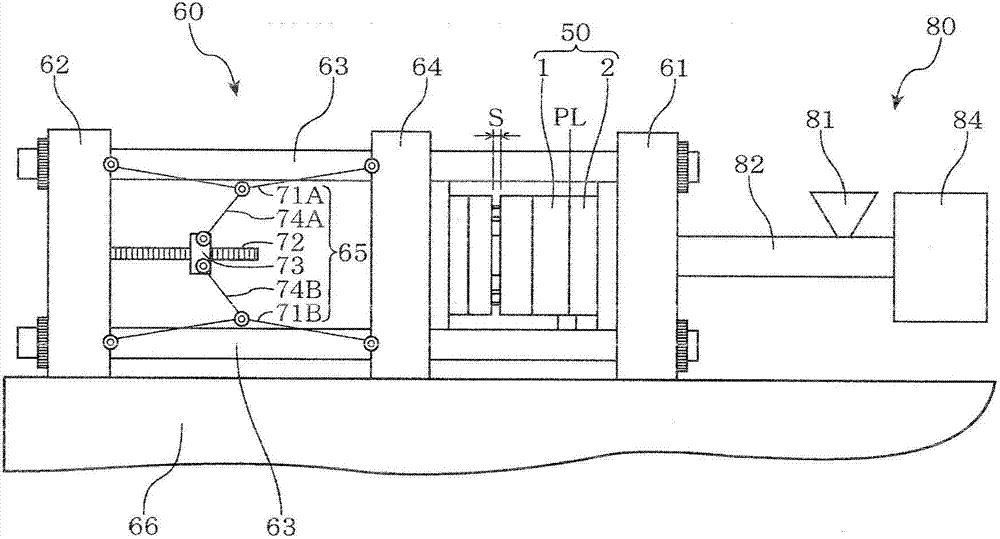

[0049] figure 1 It is an explanatory drawing which shows an example of the injection molding facility, and the manufacturing method of the plastic lens which concerns on this embodiment can be implemented suitably using such an injection molding facility.

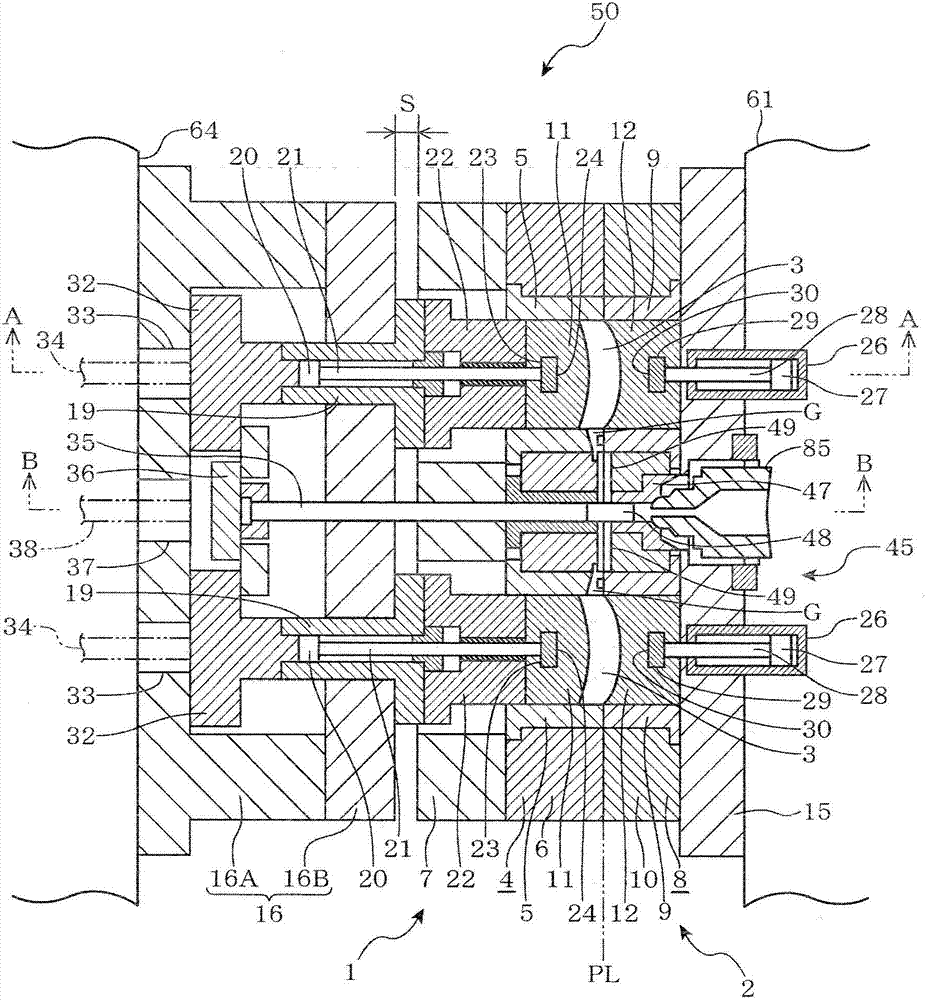

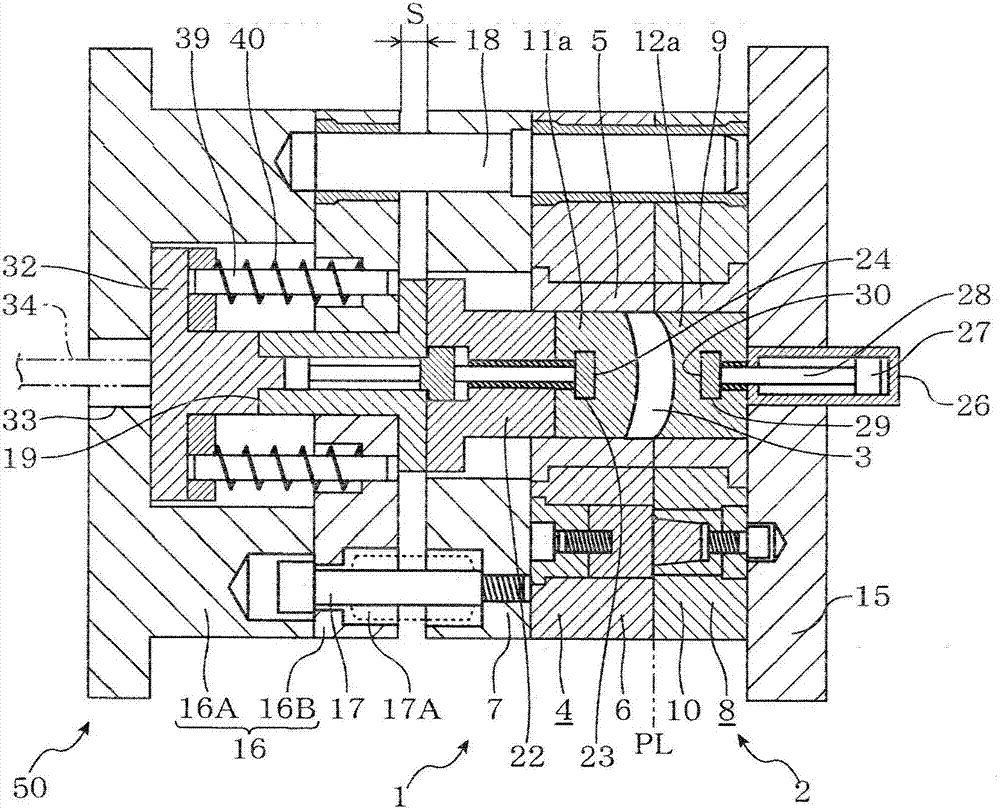

[0050] figure 1The injection molding apparatus shown is provided with a molding die 50, a clamping device 60, and an injection device 80, wherein the molding die 50 has a movable die 1 and a fixed die 2 that utilize a parting surface. (parting line) A pai...

no. 2 approach

[0105] Next, a second embodiment of the present invention will be described. In the present embodiment, a negative lens (concave lens) having a thin thickness at the center of the lens and a thick thickness at the edge of the lens is used as a molding object. Suitable for the injection molding apparatus implemented in this embodiment, except that the cavity 3 of the molding die 50 formed between the movable die 1 and the fixed die 2 is formed corresponding to the shape of the negative lens, the other components are suitable for the first injection molding machine. The injection molding apparatus implemented by the embodiment is the same. Thus, in Figure 7 to Figure 10 In the figure, a cross-section of the molding die 50 having the cavity 3 formed in accordance with the shape of the negative lens is shown, and the same reference numerals are assigned to the common components, and the repeated description of the injection molding equipment is omitted.

[0106] in addition, ...

Embodiment 1

[0118] exist figure 1 In the injection molding equipment shown, the molding surface of the insert 11 on the side of the movable mold 1 and the side of the fixed mold 2 are respectively formed using insulating materials 11a and 12a composed of crown glass raw materials and having a thermal conductivity of 1.1W / m·K. The forming surface of the insert 12.

[0119] Using this injection molding equipment, polycarbonate is used as the raw material resin and the resin temperature is set to 290°C. At the same time, the setting of the mold temperature is changed to 125°C, 115°C, 85°C, 75°C, and 55°C. , 35° C., and a plastic lens having a thickness of 10 mm at the center of the lens, a thickness of 12.5 mm at the edge of the lens, and a diameter of 77 mm was formed.

[0120] As a result of checking the surface of the molded plastic lens, no surface defects were observed when the mold temperature was set at 125°C, 115°C, 85°C, 75°C, and 55°C, and when the mold temperature was lowered to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com