Heat insulation pad pressing mold with inclined nozzle back cover

A technology of slanting nozzles and pressing molds is applied in the fields of heat insulation pad pressing and engine heat insulation layer molding, which can solve problems such as low cost, avoid resin welding marks, and solve the problem that the nozzle is easily crushed and produced. The effect of weld line, broad application prospect and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

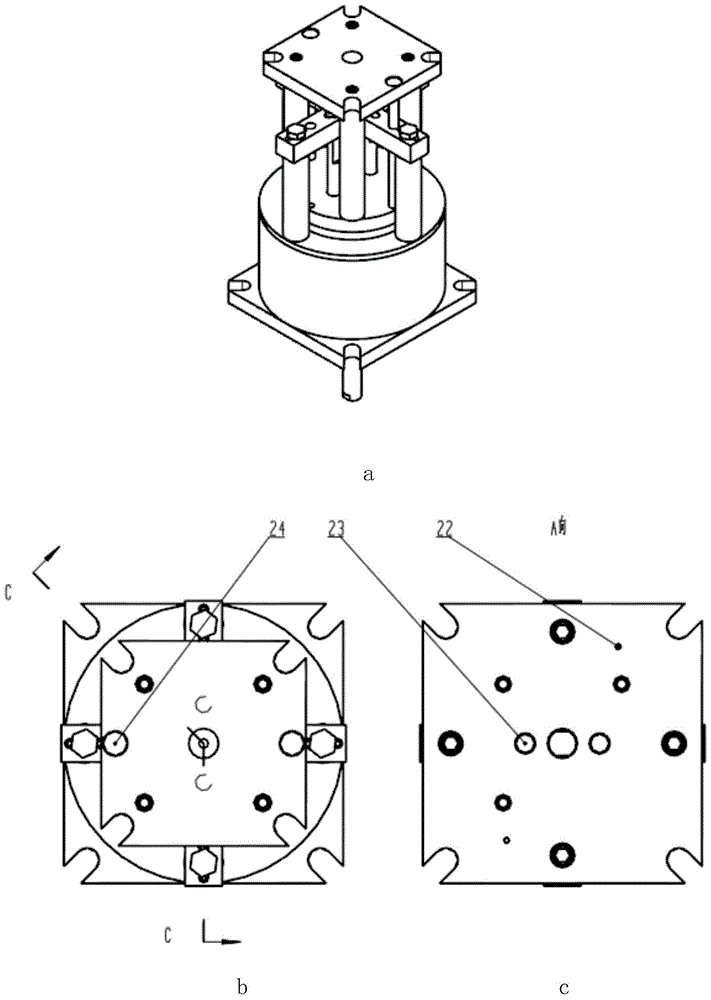

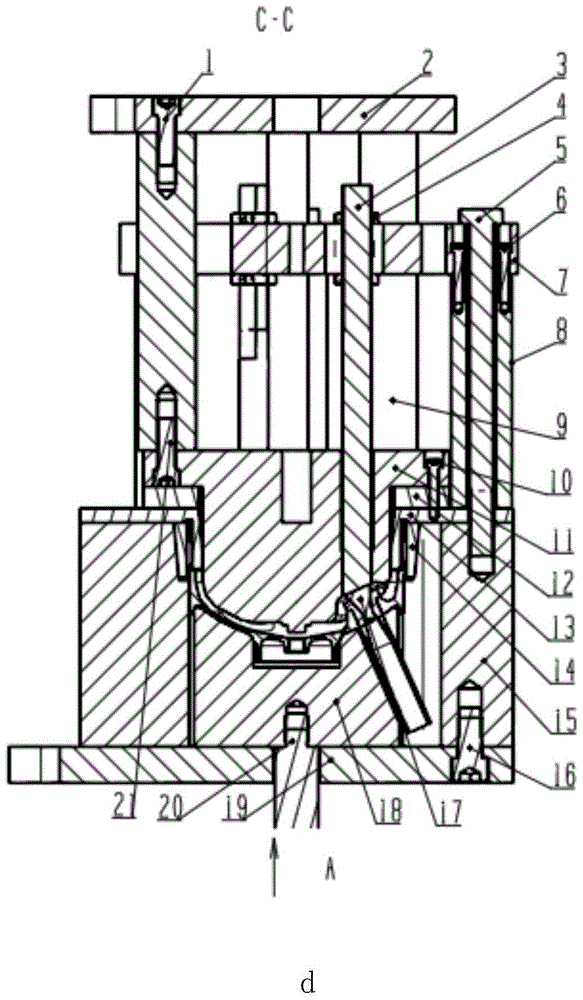

[0027] Such as figure 1 As shown in a, 1b, and 1c, a heat insulation pad pressing mold with an inclined nozzle rear cover according to the present invention is mainly composed of a male mold assembly, a nozzle protection assembly, and a female mold assembly.

[0028] The male mold assembly is connected with the upper slider of the press, and moves vertically under the action of pressure; the female mold assembly is connected with the working table of the press, and is used to place and restrain the pressed back cover; the nozzle protection assembly and the female mold assembly It is connected with special screw 5, which is used to protect the inclined nozzle during the molding process.

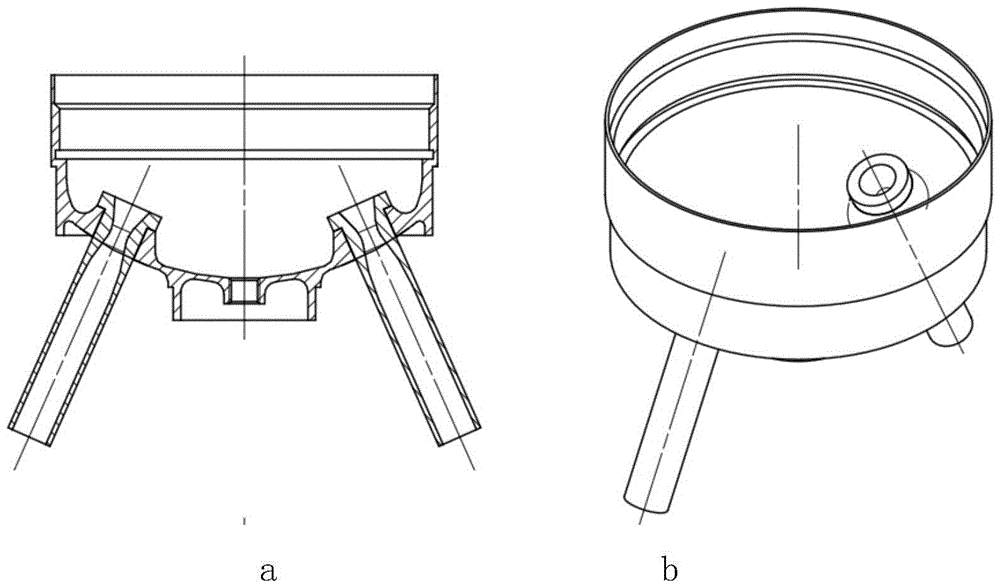

[0029] Such as figure 2 As shown in a, 2b, and 2c, it is a rear cover with an inclined nozzle, and there are two oblique nozzles on the rear cover.

[0030] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com