A kind of injection molding grade nylon engineering plastics for household appliance housing and preparation method thereof

A technology of engineering plastics and injection molding grade is applied in the field of injection molding grade nylon engineering plastics for household appliances and its preparation. Fluidity, addressing limited slip effects, low warpage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

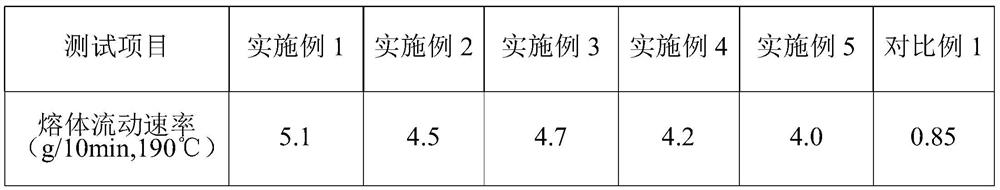

Examples

Embodiment 1

[0032] a. With 28 parts by weight of bismuth alkoxide Bi(OCH2CH2OCH3)3 as a precursor, add 3 parts by weight of methanol and 69 parts by weight of water, mix well, continue to drop ammonia water to adjust the pH value to 10, react at 25 ° C for 4h, and prepare Get bismuth sol;

[0033] b. Mix 64 parts by weight of bismuth sol prepared in step a with 32 parts by weight of flake inorganic powder and 4 parts by weight of fluorine-containing carboxylic acid into a ball mill, grind and mix until a slurry is formed, then disperse by ultrasonic vibration, and Spray-dry at 65°C, pass the collected particles through a 300-mesh standard sieve to obtain the sieved particles; wherein, the flake inorganic powder is montmorillonite passed through a 100-mesh sieve, and the fluorine-containing carboxylic acid is perfluorobutyric acid;

[0034] c. Put the sieved particles obtained in step b in a muffle furnace, feed air and slowly heat up to 520°C at a rate of 5°C / min for calcination for 4 hou...

Embodiment 2

[0037] a. Using 26 parts by weight of bismuth alkoxide Bi(OCH2CH2OCH3)3 as a precursor, add 3 parts by weight of ethanol and 71 parts by weight of water, mix well, continue to drop ammonia water to adjust the pH value to 9, and react at 22 ° C for 4.5 hours, Prepare bismuth sol;

[0038] b. Mix 65 parts by weight of bismuth sol prepared in step a with 31 parts by weight of flake inorganic powder and 4 parts by weight of fluorine-containing carboxylic acid into a ball mill, grind and mix until a slurry is formed, then disperse by ultrasonic vibration, and Spray-dry at 63°C, pass the collected particles through a 300-mesh standard sieve to obtain the sieved particles; wherein, the flaky inorganic powder is pyrophyllite passed through a 100-mesh sieve, and the fluorine-containing carboxylic acid is perfluorooctanoic acid;

[0039] c. Put the sieved particles obtained in step b in a muffle furnace, feed air and slowly heat up to 510°C at a rate of 3°C / min for calcination for 4.5h,...

Embodiment 3

[0042] a. Using 28 parts by weight of bismuth alkoxide Bi(OCH2CH2OCH3)3 as a precursor, add 4 parts by weight of propanol and 68 parts by weight of water, mix well, continue to drop ammonia water to adjust the pH value to 10, and react at 28 ° C for 3.5 hours, Prepare bismuth sol;

[0043] b. Mix 61 parts by weight of bismuth sol prepared in step a with 34 parts by weight of flake inorganic powder and 5 parts by weight of fluorine-containing carboxylic acid into a ball mill, grind and mix until a slurry is formed, then disperse by ultrasonic vibration, and Spray drying at 68°C, pass the collected particles through a 300-mesh standard sieve to obtain the sieved particles; wherein, the flake inorganic powder is muscovite passed through a 100-mesh sieve, and the fluorine-containing carboxylic acid is trifluoroacetic acid;

[0044] c. Put the sieved particles obtained in step b in a muffle furnace, feed air and slowly raise the temperature to 540°C at a rate of 8°C / min for calcina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com