Degreasing wastewater treatment device and process

A wastewater treatment and raw water technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve problems such as high technical requirements for equipment anti-corrosion, difficulty in achieving expected results, and increased project investment costs , to achieve the effect of good water discharge, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

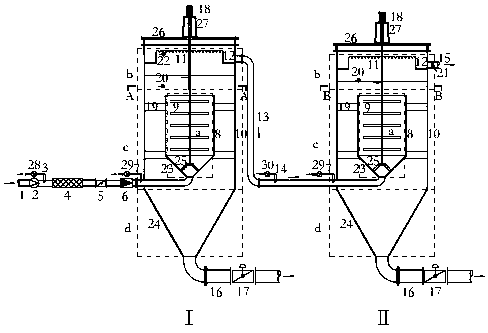

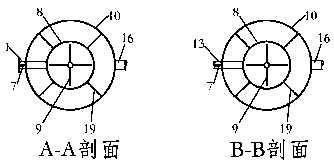

[0026] refer to figure 1 , the present invention includes main equipment, auxiliary pipelines and valve systems, and a measurement and control system. The main equipment is a primary reaction tank I and a secondary reaction tank II, and the peripheral structure is composed of an inner cylinder 8, an outer cylinder 10, a top cover 26 and bottom plates 23 and 24 of the inner and outer cylinders.

[0027] refer to figure 1 , to describe the process flow.

[0028]After the raw water is pressurized by the lifting pump 1, it enters the primary reaction tank Ⅰ from the water inlet pipe 2 through the demulsifier dosing pipe 3, the static mixer 4, the electric control valve 5, the flow meter 6 and the coagulant dosing pipe 7 to load flocculation Area a, this area is composed of inner cylinder body 8, inner cylinder bottom plate 23, agitator 9 and bearing seat 27, and agitator 9 is driven by a reduction motor 18 at the upper end of the equipment for agitation. Raw water undergoes loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com