A composite material for high-gloss spray-free asa/pmma automobile air intake grille and its preparation method

A technology of composite materials and air intake grills, applied in the field of polymer materials, to avoid flow marks, improve compatibility, and have broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

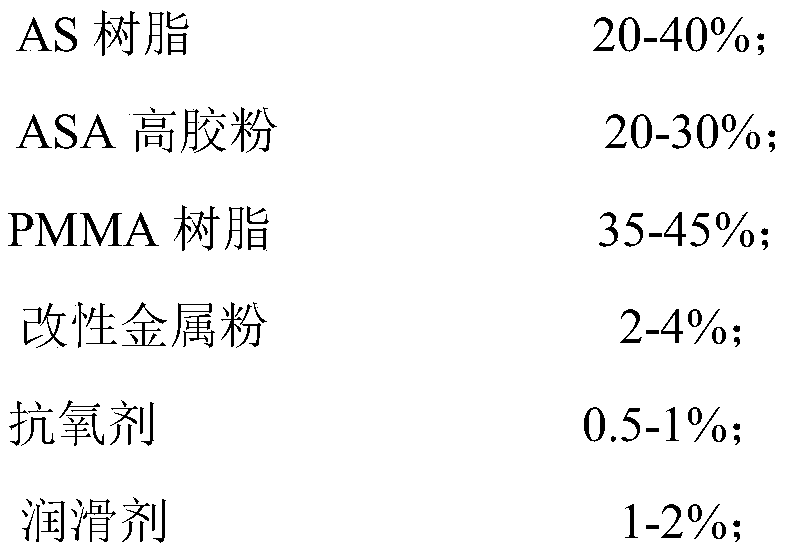

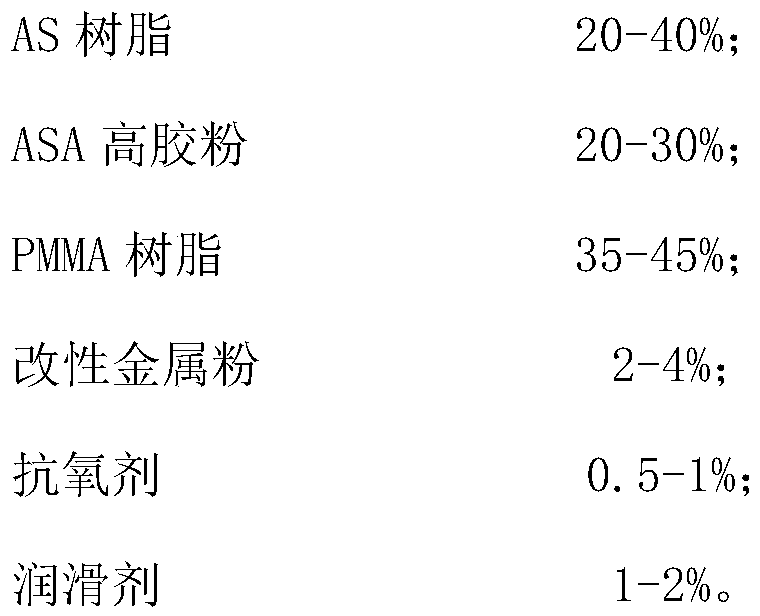

Method used

Image

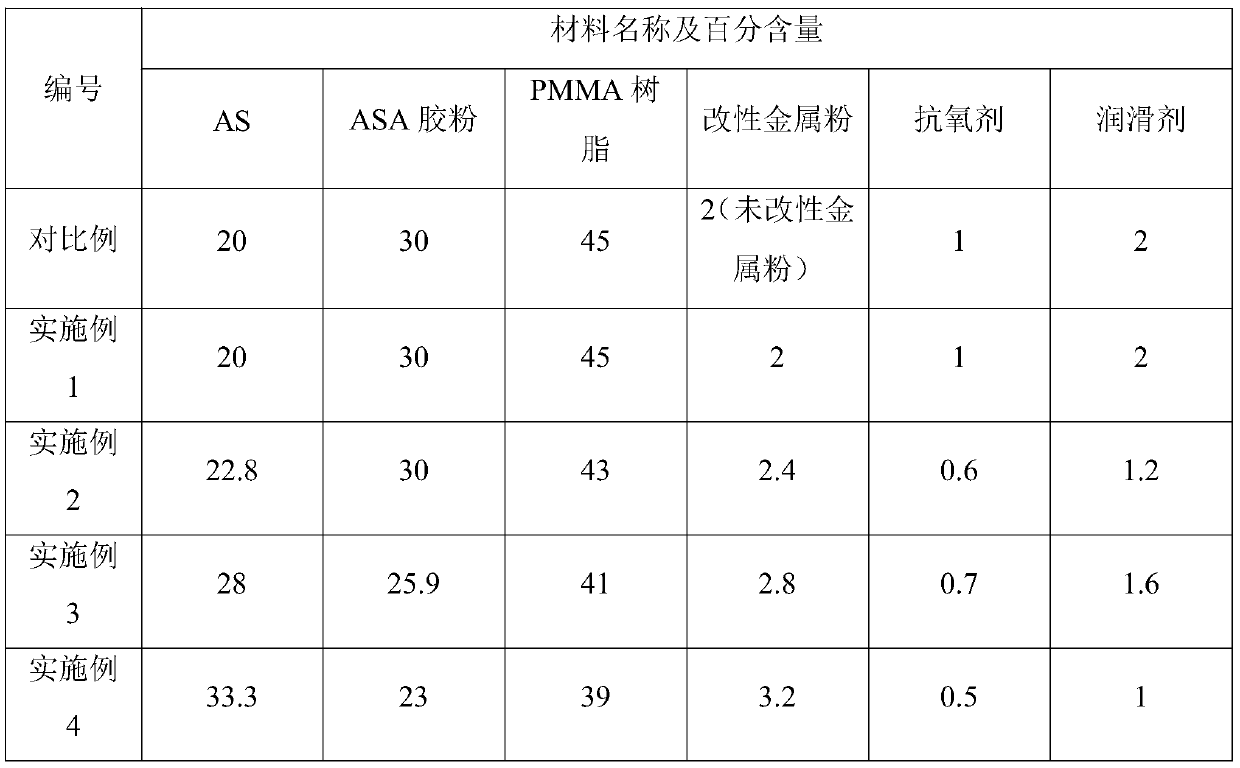

Examples

Embodiment 1

[0030] Weigh 98 parts of metal powder and 2 parts of aluminate, then add metal powder and aluminate into a high-speed mixer and stir continuously, mix for 10 minutes and take out to obtain modified metal powder.

[0031] The preparation process of the high-gloss spray-free ASA / PMMA air intake grille composite material is as follows: 20 parts of AS resin, 30 parts of ASA high rubber powder, 45 parts of PMMA resin, 2 parts of modified metal powder, 0.5 parts of antioxidant 1010, 0.5 parts of antioxidant 168 and 1.5 parts of stearic acid were put into a high-speed mixer, mixed for 5 minutes at room temperature and taken out; The obtained composite pellets were dried in a drying oven at a temperature of 85° C. for 2 hours to obtain a composite material for a high-gloss spray-free ASA / PMMA air intake grille.

Embodiment 2

[0033] Weigh 97.8 parts of the metal powder and 2.2 parts of the aluminum-titanium composite coupling agent, then add the metal powder and the aluminum-titanium composite coupling agent into a high-speed mixer and stir continuously, mix for 10 minutes, and take it out to obtain the modified metal powder.

[0034] The preparation process of the high-gloss spray-free ASA / PMMA air intake grille composite material is as follows: 22.8 parts of AS resin, 30 parts of ASA high rubber powder, 43 parts of PMMA resin, 2.4 parts of modified metal powder, 0.3 parts of antioxidant 1010, Put 0.3 parts of antioxidant 168 and 1.6 parts of silicone powder into a high-speed mixer, mix them at room temperature for 5 minutes, and take them out; melt and extrude the above-mentioned blended material through a twin-screw extruder, cool it, and granulate it. The obtained composite pellets were dried in a drying oven at a temperature of 85° C. for 2 hours to obtain a composite material for a high-gloss ...

Embodiment 3

[0036] Weigh 97.6 parts of the metal powder and 2.4 parts of the silane coupling agent, then add the metal powder and the silane coupling agent into a high-speed mixer and stir continuously, mix for 10 minutes and take it out to obtain the modified metal powder.

[0037] The preparation process of the high-gloss spray-free ASA / PMMA air intake grille composite material is as follows: 28 parts of AS resin, 25.9 parts of ASA high rubber powder, 41 parts of PMMA resin, 2.8 parts of modified metal powder, 0.35 parts of antioxidant 1010, 0.35 parts of antioxidant 168 and 1.6 parts of EBS were put into a high-speed mixer, mixed for 5 minutes at room temperature and taken out; the above-mentioned homogeneously mixed blend was melt-extruded through a twin-screw extruder, cooled, and granulated, and the obtained The composite pellets were dried in a drying oven at a temperature of 85° C. for 2 hours to obtain a composite material for a high-gloss spray-free ASA / PMMA air intake grille.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com