An automatic liquid-shielding plastic glass and its spray coating method

A technology of plastic glass and automatic blocking, which is applied in the direction of chemical instruments and methods, coatings, synthetic resin layered products, etc. It can solve the problems that are not conducive to ensuring product quality and the appearance of flow marks on the transparent layer, so as to avoid the retention of coating liquid , Guarantee surface quality and prevent flow marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

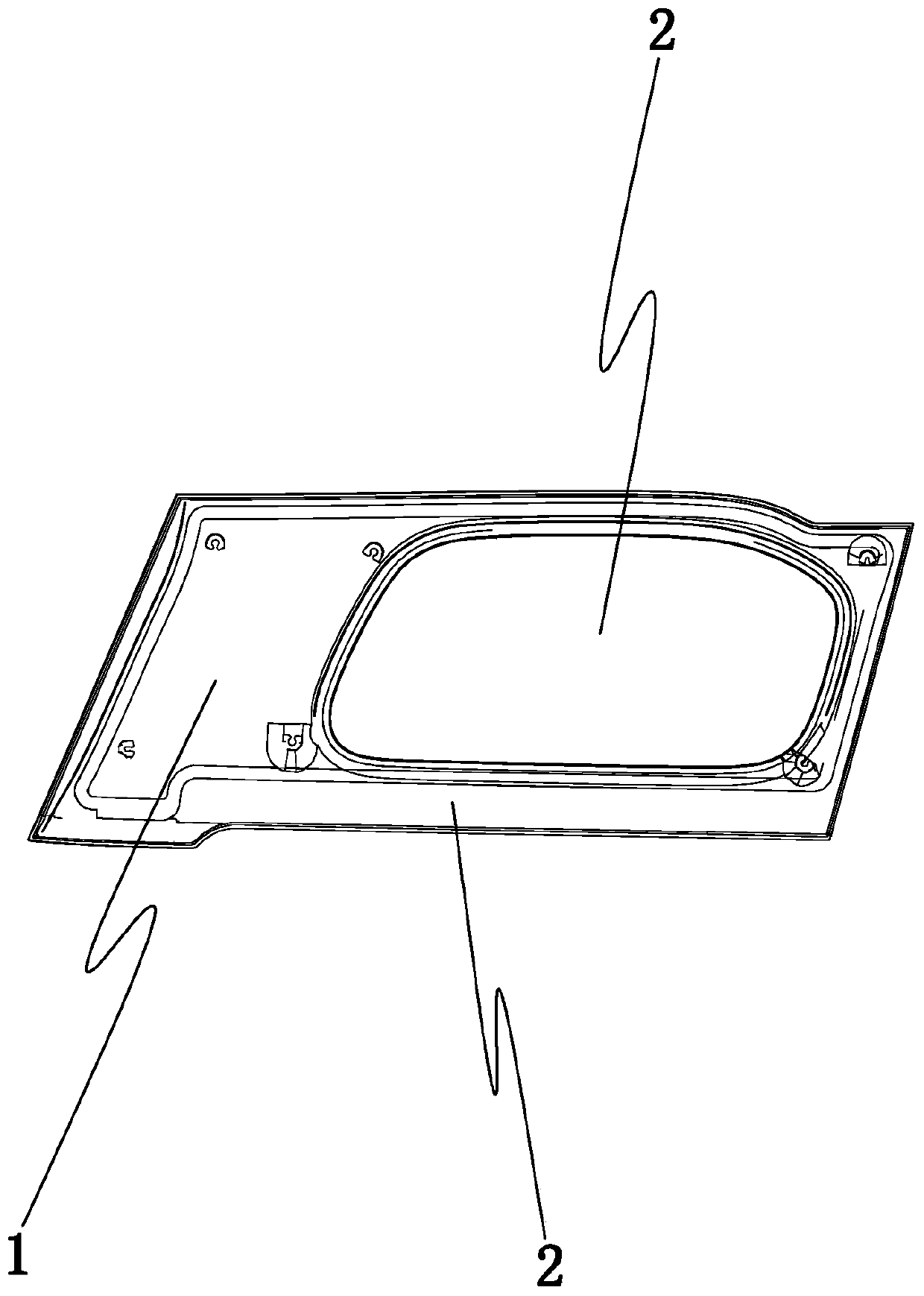

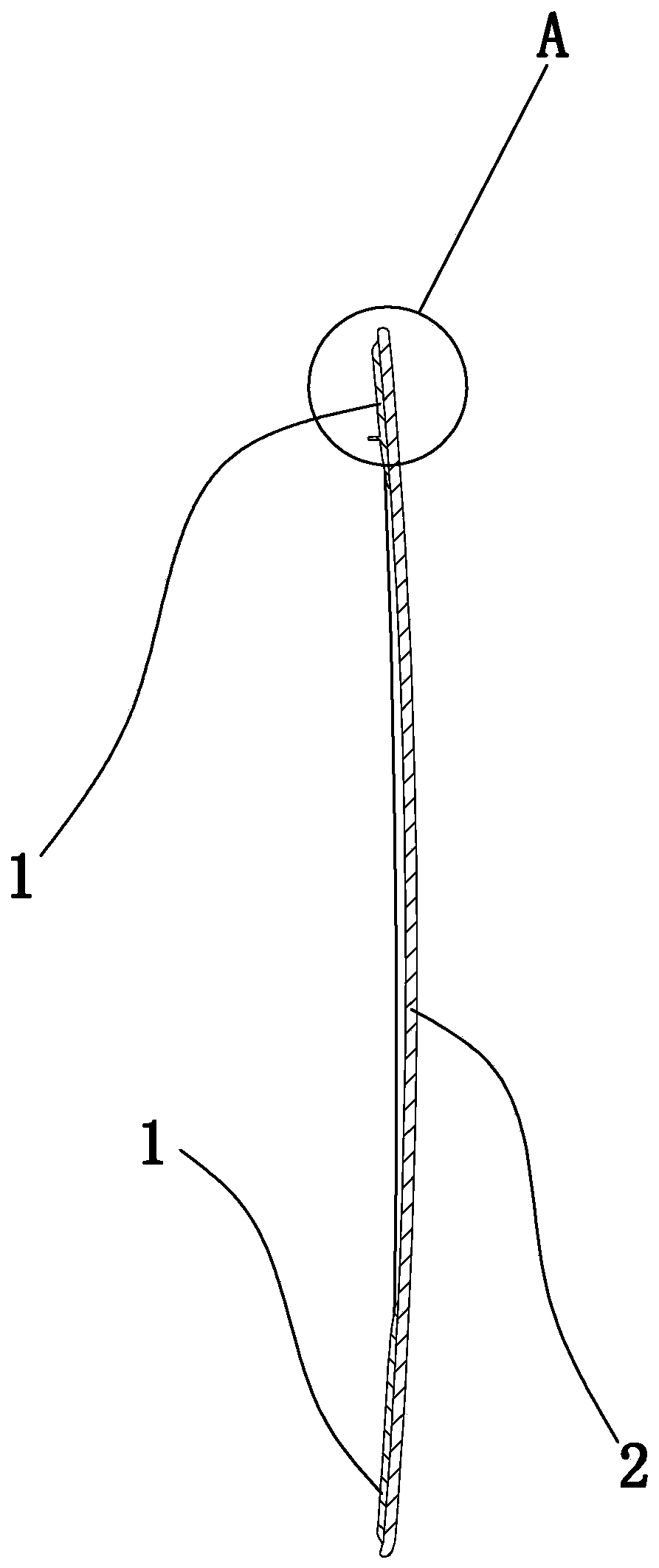

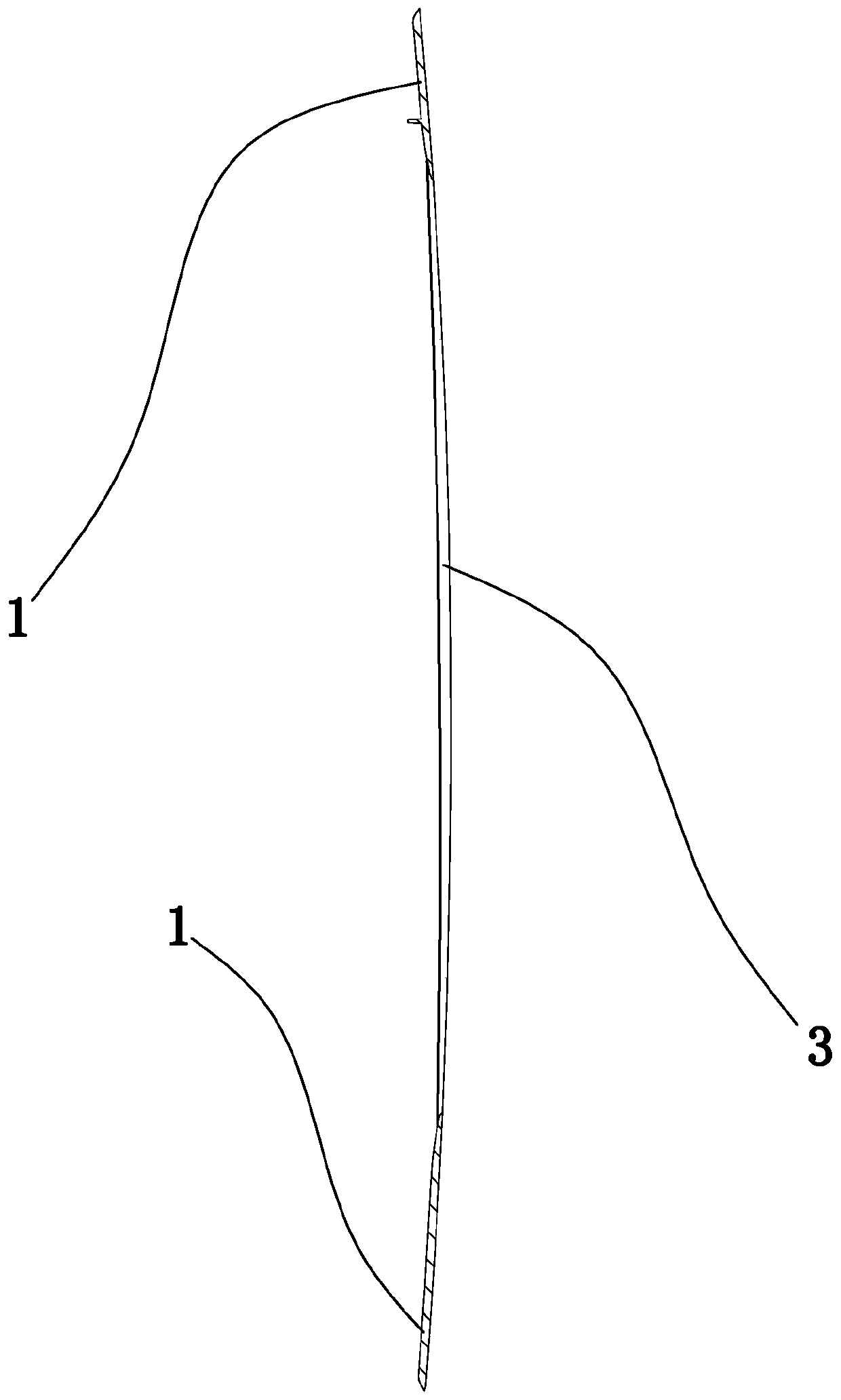

[0028] Such as Figure 1 to Figure 6 As shown, an automatic liquid-shielding plastic glass, including

[0029] A black border layer 1 and a transparent layer 2, the black border layer is connected to the transparent layer;

[0030] The black edge layer is provided with a curtain coating rib 3, and the black edge layer is between the curtain coating rib and the transparent layer;

[0031] The black border layer is provided with a through hole 4, one end of the through hole is the outer opening end, the other end of the through hole is the inner opening end, and the transparent layer seals the inner opening end.

[0032] When performing front-side flow coating, when part of the spray liquid flows to the back, it will flow down along the back. Due to the existence of the flow-coating ribs, the shower liquid will be blocked by the flow-coating ribs and fall directly without reaching the back. Appearance surface (appearance surface on the back of the transparent layer), which can...

Embodiment 2

[0039] On the basis of Example 1, such as Figure 7 As shown in , the black edge layer includes a body plate 2a and an outer ring plate 2b, the outer ring plate is provided with an inner hole, the body plate is located in the inner hole, the through hole is arranged on the body plate, the outer ring plate and The body boards are clamped, and the body board is connected with the transparent layer. The outer ring plate and the body plate are connected by a snap-in structure, and the snap-in structure includes a number of elastic protrusions 5 arranged on the wall of the inner hole and a number of snap holes arranged on the outer edge of the body plate. The protrusions correspond to the clamping holes one by one, and the elastic protrusions are clamped in the corresponding clamping holes.

[0040] During flow coating, quality problems are most likely to occur near the junction of the outer edge of the black edge layer and the transparent layer, and the outer edge of the black ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com