A structure to prevent the rubber in the gate from breaking in the mold

An in-mold and rubber material technology is applied in the structural field where the rubber material is broken in the mold, which can solve the problems of mold damage, inability to reset, and remaining in the mold, so as to improve the service life, avoid flow marks and air bubbles, and reduce glue The effect of the amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

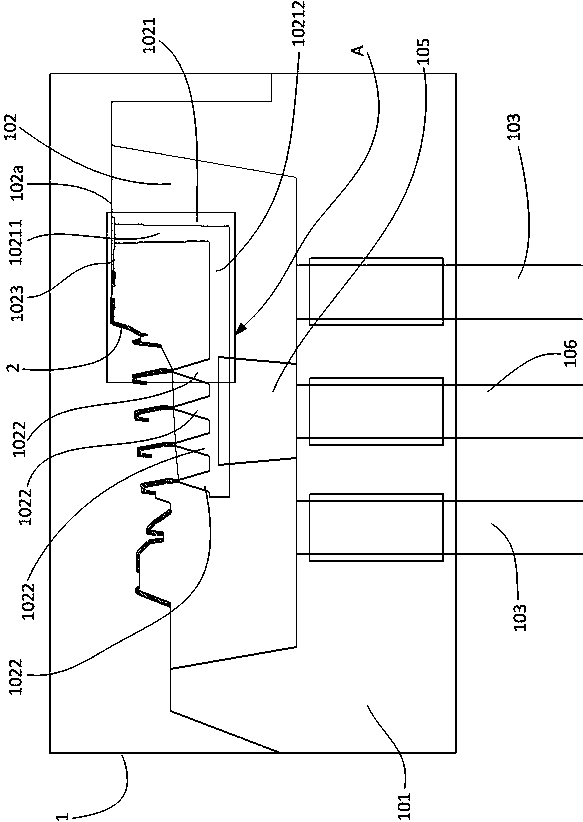

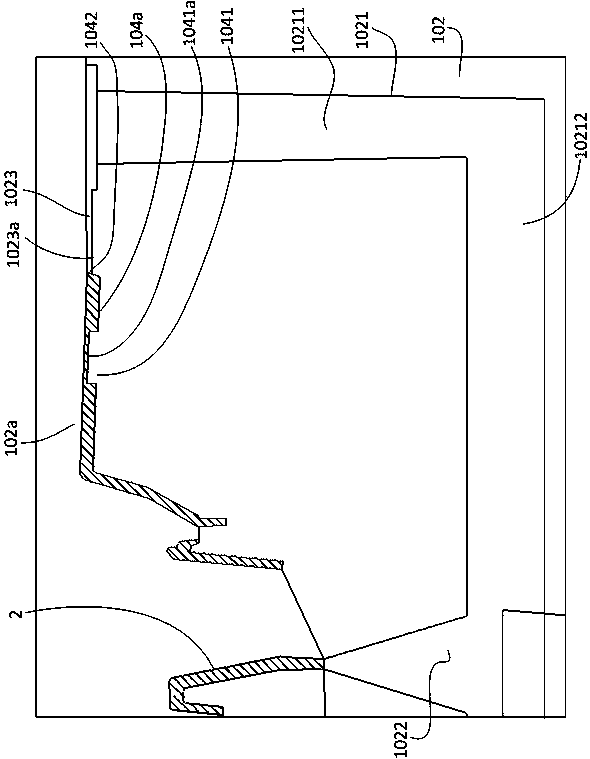

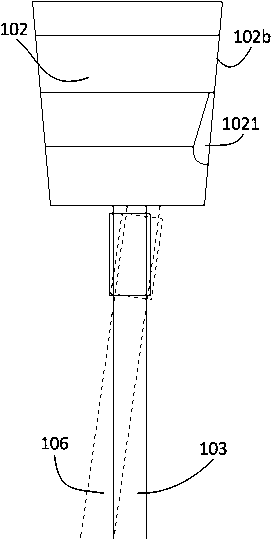

[0019] Please refer to Figure 1 to Figure 5 , the embodiment of the present invention prevents the rubber material in the gate from breaking in the mold structure, which includes a front mold and a rear mold 1 that cooperates with the front mold, and the front mold and the rear mold 1 are molded together to form a mold cavity. The back mold 1 is provided with a glue feeding channel, and the back mold 1 includes a back mold core 101, a straight jack block 102 arranged in the back mold core 101, and a straight jack rod 103 for driving the straight jack block 102 to move up and down. , the upper end of the rear mold 1 has a cavity forming portion 104 that forms the peripheral surface of the cavity, and one side of the straight top block 102 is provided with a glue inlet channel forming portion 1021 that forms the peripheral surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com