A smokeless polishing solution for aluminum

A technology of polishing liquid and aluminum materials, which is applied in the field of metal surface treatment, can solve the problems of flow marks, yellow smoke, and failure to meet brightness requirements, etc., and achieve the effects of improving brightness, avoiding flow marks, and overcoming poor mirror effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

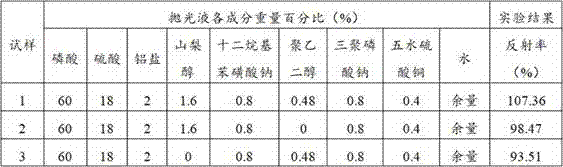

Image

Examples

Embodiment 1

[0072] The polishing liquid is prepared according to the raw materials of percentage by weight:

[0073] 58% phosphoric acid, 18% sulfuric acid, 2% aluminum salt, 1.5% sorbitol, 0.8% sodium dodecylbenzenesulfonate, 0.4% polyethylene glycol, 0.6% sodium tripolyphosphate, 0.4% pentahydrate copper sulfate, and the balance is water.

[0074] Put the aluminum material in the polishing solution, soak it for 1-5 minutes at a temperature of 90-110°C, take out the aluminum material and hang it for 20-30 seconds, clean and dry. Observe for smoke generation and for flow marks and shiny spots on the aluminum surface.

Embodiment 2

[0076] The polishing liquid is prepared according to the raw materials of percentage by weight:

[0077] 60% phosphoric acid, 19% sulfuric acid, 3% aluminum salt, 1.8% sorbitol, 1% sodium dodecylbenzenesulfonate, 0.3% polyethylene glycol, 0.4% sodium tripolyphosphate, 0.6% copper sulfate pentahydrate, The balance is water.

[0078] Put the aluminum material in the polishing solution, soak it for 1-5 minutes at a temperature of 90-110°C, take out the aluminum material and hang it for 20-30 seconds, clean and dry. Observe for smoke generation and for flow marks and shiny spots on the aluminum surface.

Embodiment 3

[0080] The polishing liquid is prepared according to the raw materials of percentage by weight:

[0081] 62% phosphoric acid, 16% sulfuric acid, 3% aluminum salt, 1.2% sorbitol, 0.9% sodium dodecylbenzenesulfonate, 0.5% polyethylene glycol, 0.8% sodium tripolyphosphate, 0.5% copper sulfate pentahydrate, The balance is water.

[0082] Put the aluminum material in the polishing solution, soak it for 1-5 minutes at a temperature of 90-110°C, take out the aluminum material and hang it for 20-30 seconds, clean and dry. Observe for smoke generation and for flow marks and shiny spots on the aluminum surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com