Resin molded body and method for producing the same

A technology of resin molding and molten resin, which is applied in the fields of magnetism, transportation and packaging, decorative arts, etc. of organic materials/organic magnetic materials, and can solve the problem of not being able to give enough metal texture and bright appearance, and resin moldings cannot provide high quality Texture and other problems, to achieve the effect of eliminating peeling and rusting problems, excellent metal texture and bright appearance, good metal texture and bright appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

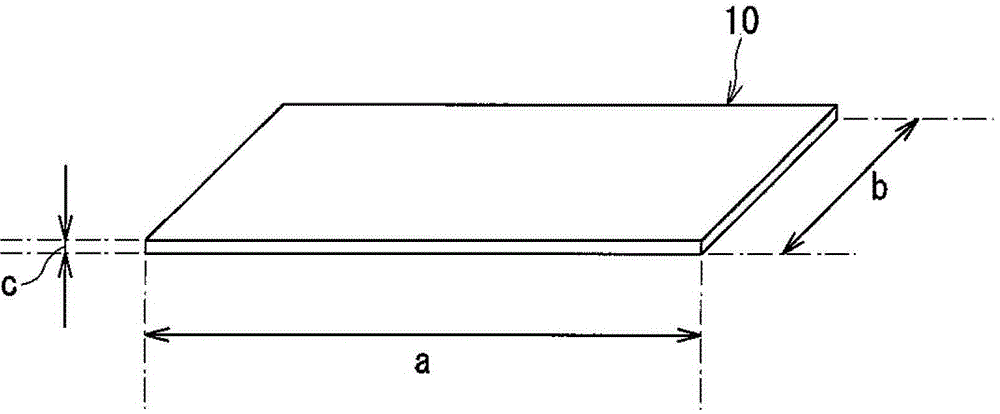

[0144] A room temperature curing type liquid silicone rubber having a viscosity of 100 Pa·s was prepared as the resin material of Sample 26. A scaly PC permalloy flake with an average particle size of 24 μm and an aspect ratio of 40 was prepared as the ferromagnetic brightener 10 . Next, the prepared ferromagnetic brightener 10 was added and uniformly dispersed in the prepared sample 26, thereby obtaining a slurry. The addition rate of the ferromagnetic brightener 10 is as low as 10wt%, such as 2wt%. The slurry thus obtained was poured into a non-magnetic glass container 25 (cavity) with a diameter of 20 mm and a thickness of 2 mm, and the container 25 was placed in Figure 8A and Figure 8B On the turntable 20 of the rotating magnetic field apparatus 15 shown in. Experiment in this state.

[0145] Next, at Figure 8A and Figure 8B In the rotating magnetic field apparatus 15 shown in , a rotating magnetic field was applied to the target at a rotational speed of 40 rpm b...

Embodiment 2

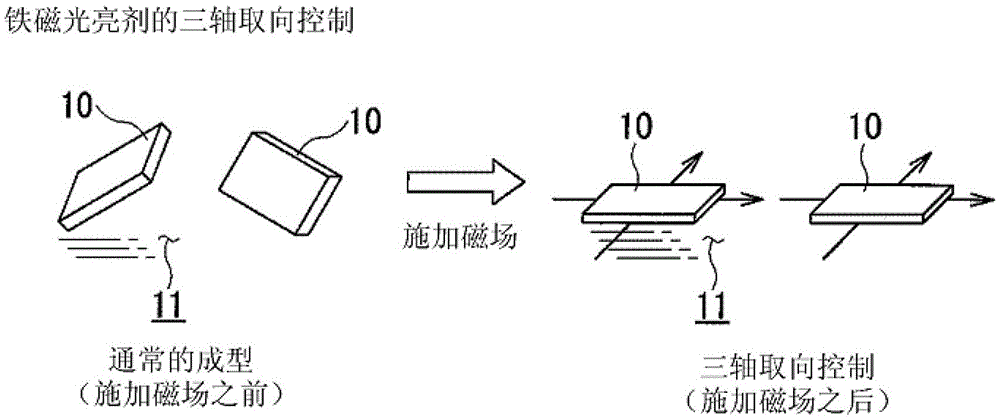

[0161] Regarding the three-axis orientation control of ferromagnetic brighteners, using Figure 9A and Figure 9B Experiments were conducted with the rotating magnetic field apparatus 16 shown in , in order to prove that the ab surfaces of all the particles of the ferromagnetic brightener 10 added to the resin material of the sample 26 faced the upper surface of the sample 26 (triaxial orientation control state) . In the rotating magnetic field device 16, the sample 26 is placed in the region between the magnetic poles 17 and 18, which has a uniform magnetic field without a magnetic field gradient. Experiments were conducted using the rotating magnetic field apparatus 16 under the condition that only triaxial orientation control was performed on the permalloy flakes as the ferromagnetic brightener 10 added to the molten resin 11 .

[0162] Scale-like PC permalloy flakes (ferromagnetic brightener 10) with an average particle size of 24 μm and an aspect ratio of 40 were added ...

Embodiment 3

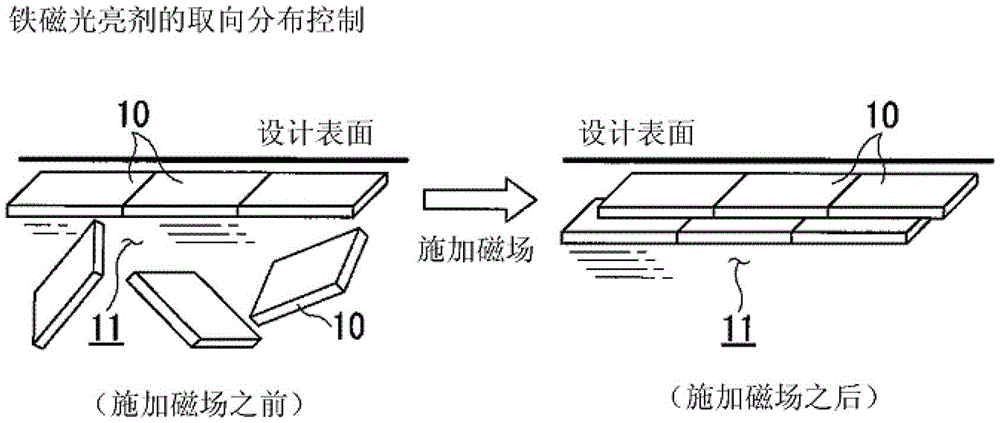

[0165] With regard to the orientation distribution control of the ferromagnetic brightener, a confirmatory experiment on the displacement motion was performed using a PC permalloy flake as the ferromagnetic brightener 10 of Example 1, in order to prove that iron is controlled inside the molten resin 11 of the sample 26. Orientation (arrangement) distribution of the magnetic brightener 10.

[0166] In Example 3, the flaky PC permalloy flakes (ferromagnetic brightener 10) with an average particle size of 24 μm and an aspect ratio of 40 were added and uniformly dispersed into room temperature curing liquid silicone rubber with a viscosity of 100 Pa s ( resin material), thus obtaining a slurry.

[0167] The addition rate of the ferromagnetic brightener 10 is low, for example 2wt%. Furthermore, a room-temperature-curing liquid silicone rubber without additives was placed on the slurry thus obtained. The same experiment as in Example 1 was carried out under this condition.

[016...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com