Method for improving joint strength of polyethylene and metalwork

A connection strength and polyethylene technology, which is applied in the field of strengthening the connection strength of polyethylene with metal parts and copper metal parts, can solve the problems of unstable performance, bubble accumulation, high cost, etc., and achieve good product consistency, stable performance, The effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

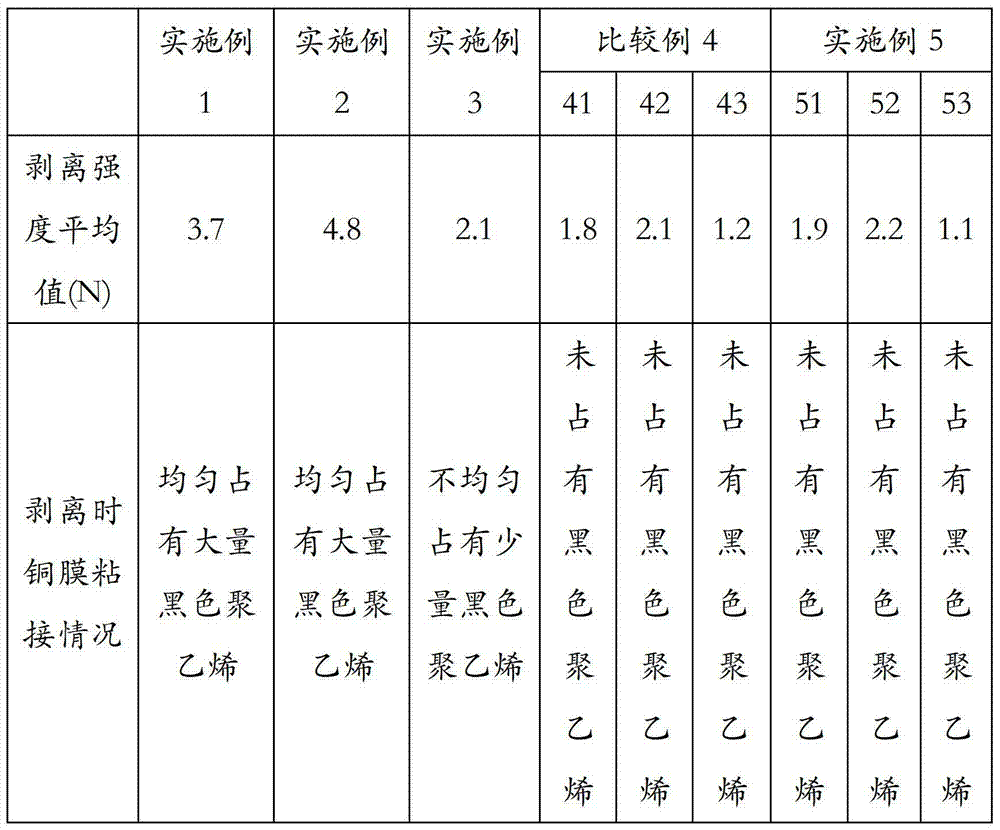

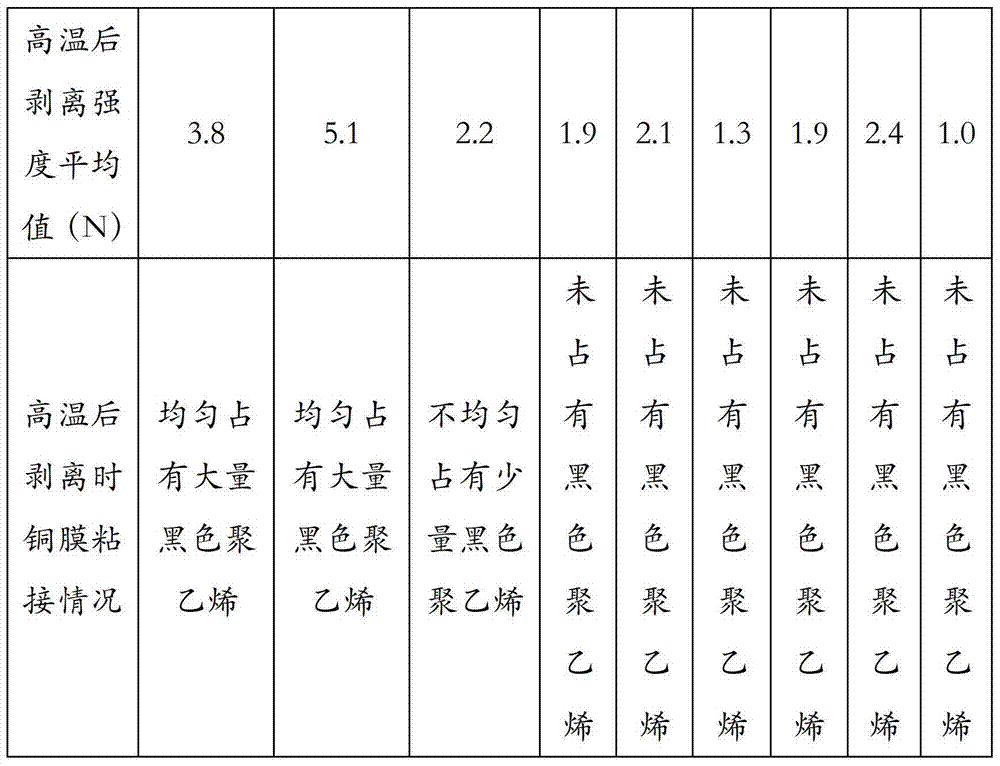

Embodiment 1

[0019] 100 grams of high-density polyethylene HDPE (Phillips HXM-50100-001, melting point 130-150 ° C, density 0.943 g / cm3, Vicat softening point 124 ° C), 186 grams of conductive carbon black N990 and 46 grams of magnesium hydroxide , in a high-speed kneader at 170°C to knead into a dough and then knead for 15 minutes, make a triangular bag and then crush it. The polyethylene composite sheet is subjected to stress relief and shrinkage under 130°C and 5MPa hot pressing. Pass the treated polyethylene composite sheet through C o 60 irradiation, the irradiation dose is 15Mard, the irradiated polyethylene composite sheet is covered with roughened copper film on both sides, and pressed at 185°C and 5MPa for 3 minutes to form a polyethylene copper clad sheet. Test the peel strength according to the national standard "GB / T 13557-92 Test Method for Flexible Materials for Printed Circuits". After the test, observe the color of the peeled copper film on the polyethylene composite, and ...

Embodiment 2

[0021] Polyethylene compound manufacture step is the same as embodiment 1, polyethylene compound is broken into pellets, through C o 60 irradiation, the irradiation dose is 7Mard, weigh 10g of the irradiated polyethylene composite broken material, place it on the roughened copper film, and then place a layer of roughened copper film, at 185°C, 15MPa Press down and press for 3 minutes to form a polyethylene copper clad sheet.

Embodiment 3

[0023] 12 grams of linear low-density polyethylene LLDPE (Sinopec DFDC-7050, density 0.923g / cm3), 23 grams of high-density polyethylene HDPE (Taiwan Formosa Plastics 8003, density 0.958g / cm3, melting point 134 ° C, softening point 127 ° C ), 11 grams of ethylene-vinyl acetate copolymer EVA and 25 grams of conductive carbon black N990, 27 grams of aluminum hydroxide are mixed to form polyethylene composites. The composite is crushed into pellets, and then molded to form a 1.0-2.0mm plate, and the pellets and the plate are subjected to C o 60 irradiation, the irradiation dose is 0.75Mard. After irradiation, the fixed mold is used to cover the film and heat the molding to bond the smooth copper foil and the polyethylene compound. Test its bonding strength according to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com