Polyamide material with metal texture and preparation method thereof

A polyamide and metal toner technology, applied in the field of materials, can solve the problems that cannot be effectively controlled and solved, and the mechanical properties and surface properties of the metal texture are difficult to balance, so as to achieve excellent mechanical properties and processing properties, improve dispersibility, and guarantee The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

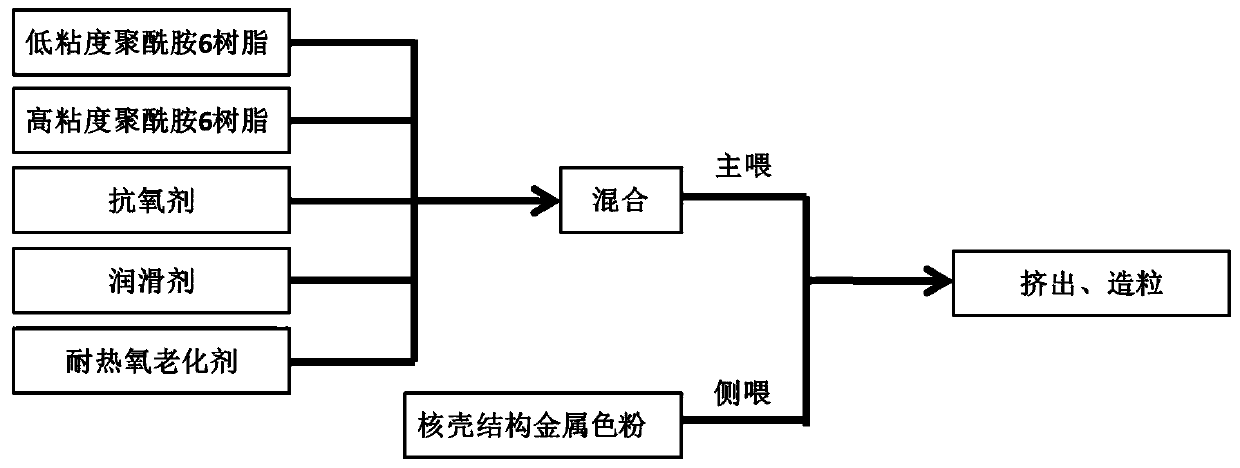

[0038] A kind of preparation method of polyamide material of the present invention, comprises the raw material described in any one in above low-viscosity polyamide 6 resin, high-viscosity polyamide 6 resin, antioxidant, lubricant, heat-resistant oxygen aging agent, It is weighed according to the weight fraction, mixed with a high-speed mixer, and the main feed is fed into a twin-screw extruder; the metal toner with a core-shell structure is fed into a twin-screw extruder through side feed, and then melted and extruded to obtain granules.

[0039] Preferably, the mixing speed of the high-speed mixer is 500-1200 rpm. Preferably, the process parameters of melt extrusion granulation of the twin-screw extruder are as follows: the temperature of the first zone is 245-265°C, the temperature of the second zone is 250-270°C, the temperature of the third zone is 250-270°C, and the temperature of the fourth zone is 250-270°C. 255~275℃, 255~275℃ in zone 5, 250~270℃ in zone 6, 250~270℃ in...

Embodiment 1

[0056] A kind of core-shell structure metal color powder spray-free polyamide material, comprising the following components by weight:

[0057]

[0058] Among them, the core-shell structure method of the metal toner with a core-shell structure is as follows: 1) First, add acrylic acid to water to form an aqueous solution with a concentration of 0.001g / L; Stir in the acrylic acid aqueous solution described in 1) for 0.5h, filter, wash and dry to obtain pretreated metallic toner; 3) add methyl acrylate monomer into ethanol to form a 0.001g / L solution; 4) mix Add the pretreated metal toner to the solution described in 3), and add azobisisoheptanonitrile at the same time, raise the temperature to 60°C under stirring to initiate polymerization, and react for 0.5h, filter, wash and dry, and finally obtain the core-shell structure metal toner.

[0059] The above-mentioned a kind of core-shell structure metal color powder spray-free polyamide material and its preparation method co...

Embodiment 2

[0065] A kind of core-shell structure metal color powder spray-free polyamide material, comprising the following components by weight:

[0066]

[0067] Among them, the core-shell structure method of the metal toner with the core-shell structure is as follows: 1) First, polyacrylic acid with a molecular weight of 20,000 is added to water to form an aqueous solution with a concentration of 0.01 g / L; Add the concentration of g / L into the polyacrylic acid aqueous solution described in 1) and stir for 3 hours, then filter, wash and dry to obtain the pretreated metal toner; L solution; 4) Add the pre-treated metal toner to the solution described in 3), add benzoyl peroxide at the same time, heat up to 70°C under stirring to initiate polymerization, react for 3 hours, filter, wash and dry, and finally The metal toner with core-shell structure is obtained.

[0068] The above-mentioned a kind of core-shell structure metal color powder spray-free polyamide material and its preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com