Suction liquid discharge assisted double-narrow-slit electrolytic cutting machining device and method

A technology for cutting and electrolytic machining machine tools, which is applied in the field of suction and drainage auxiliary double-slot liquid-spraying electrolytic cutting processing devices, can solve the problems of low processing speed, unstable processing, electrode loss, etc., and achieves processing effect and processing speed. Improve, improve processing efficiency and processing quality, the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

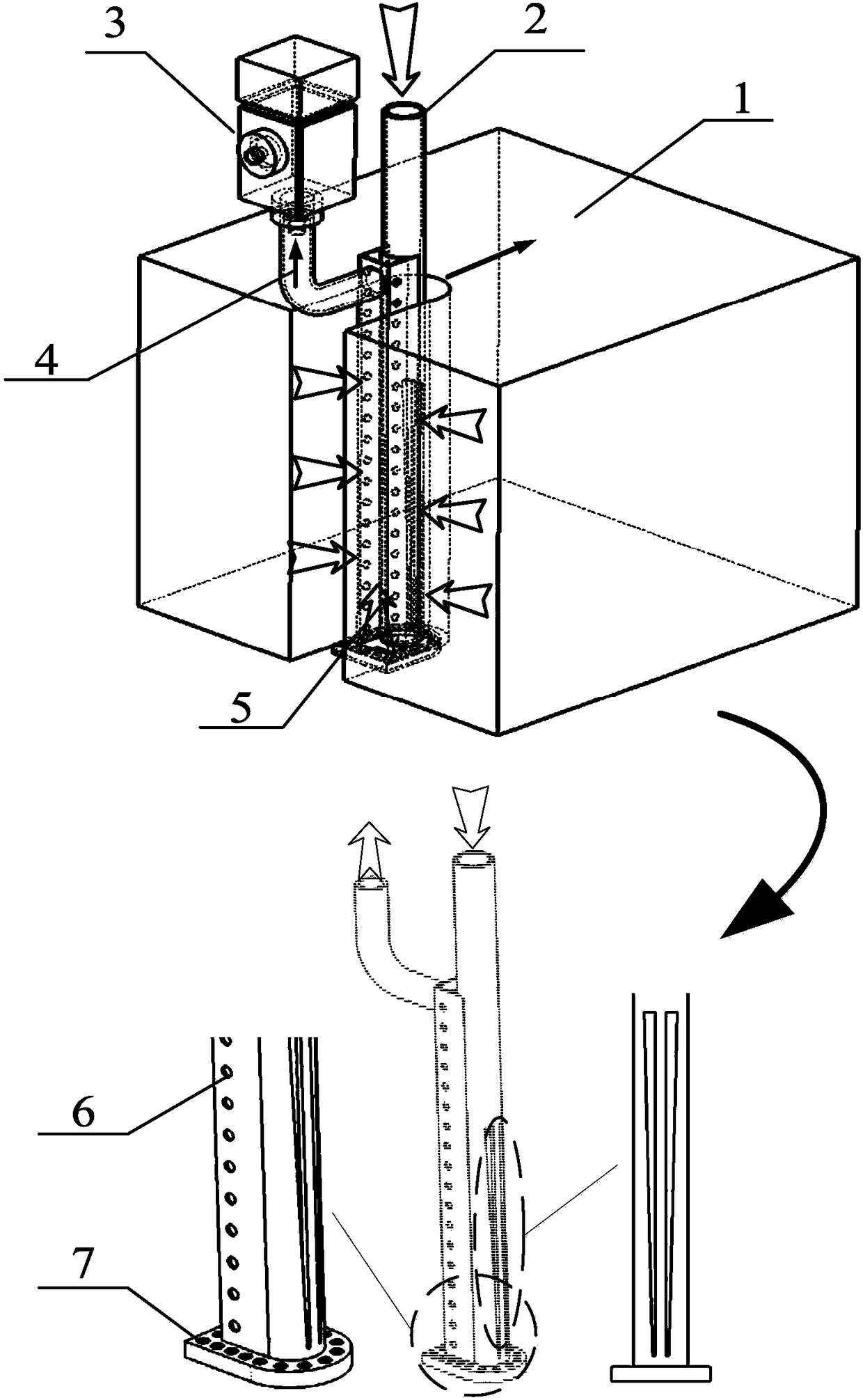

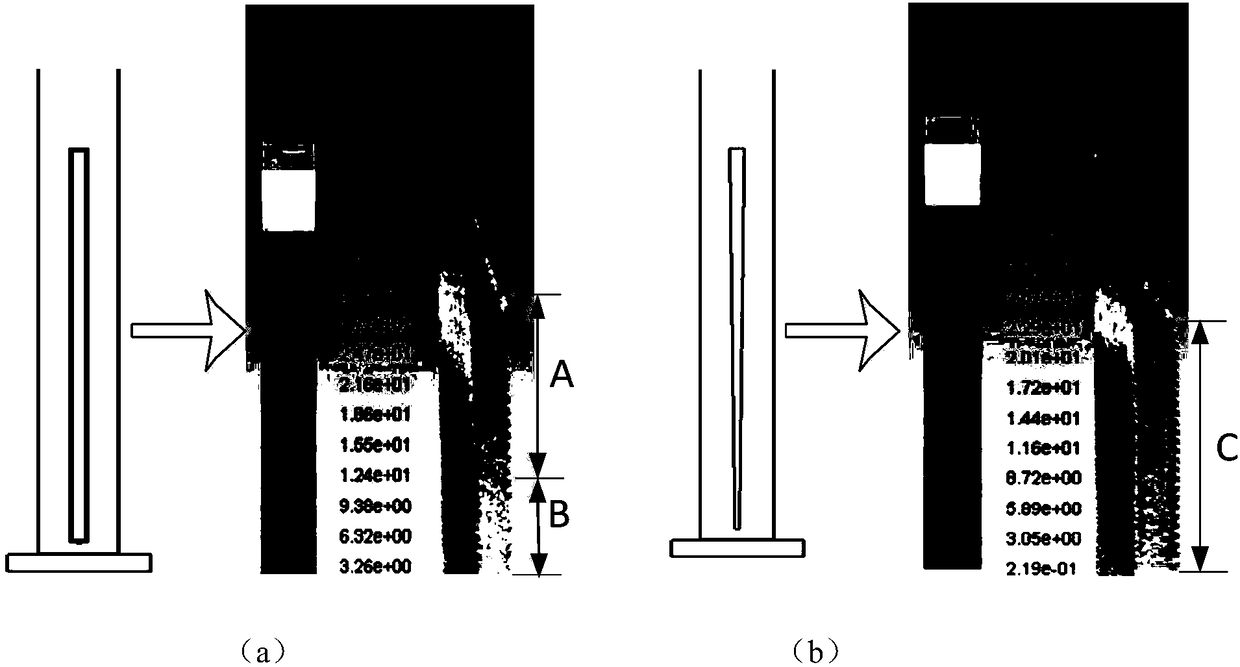

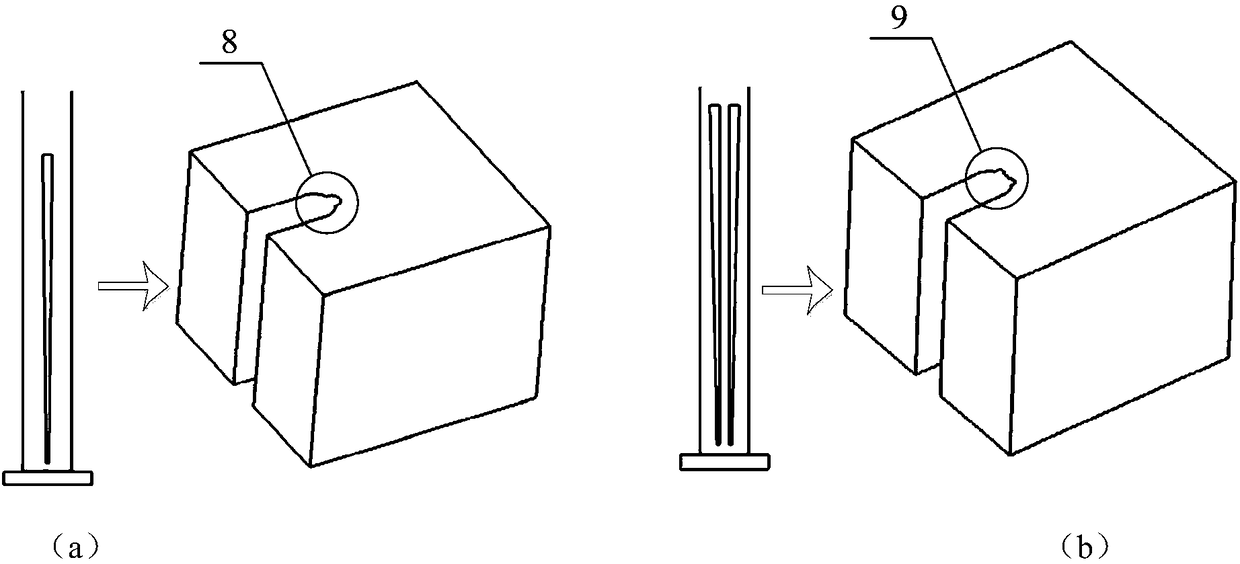

[0033] figure 1 In the schematic diagram of suction and drainage assisted double narrow slit liquid spray electrolytic cutting shown, firstly adjust the distance between the liquid spray slit of the tube electrode 2 and the workpiece 1, and ensure that the liquid spray slit of the tube electrode 2 is facing the workpiece 1; then , turn on the constant pressure pump 16, and adjust the hydraulic pressure parameters; finally, set the cutting curve in the control system, turn on the power to start processing, and after the processing tool is completely cut into the workpiece, turn on the suction pump 3, and adjust the suction of the liquid pump. Hydraulic pressure parameters to ensure the balance of liquid supply and pumping.

[0034] figure 2 In the schematic diagram of the suction and discharge auxiliary double narrow slit liquid spray electrolytic cutting processing device shown, the industrial computer 11 and the computer 12 are the main control systems of the electrolytic j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com