Spraying-free aesthetic resin composition with magnetism and preparation method thereof

A technology of aesthetic resin and composition, which is applied in the field of resin formula and its preparation, can solve the problems of limiting the effect range of spray-free aesthetic resin, aggravating flow marks and weld lines, increasing the amount of special effect toner, etc., to achieve performance improvement, Effects that reduce flow marks and weld lines, and enhance metallic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment relates to a magnetic spray-free aesthetic resin composition. The preparation method includes the following steps:

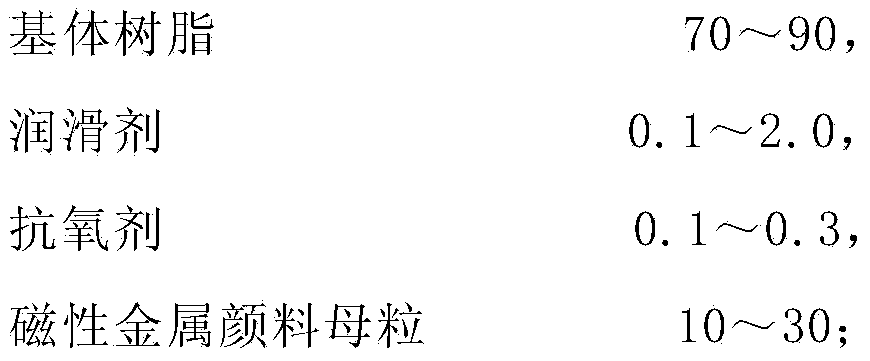

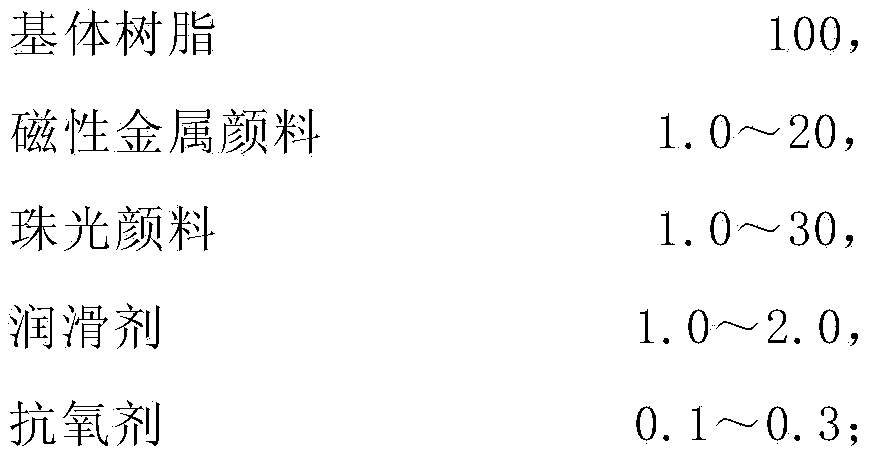

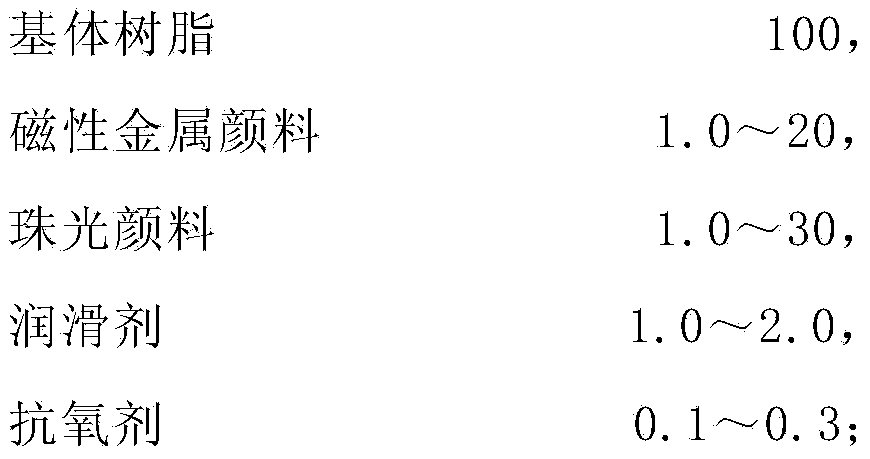

[0043] (1) Prepare materials according to the following components and parts by weight:

[0044] Base resin 100,

[0045] Magnetic Metal Pigments 8.0,

[0046] Pearlescent Pigment 8.0,

[0047] Lubricant 2.0,

[0048] Antioxidant 0.3;

[0049] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then the master batches containing magnetic metal pigments are obtained through the steps of extrusion, drawing, cooling and pelletizing.

[0050] (3) Prepare materials according to the following components and parts by weight:

[0051] Base resin 90,

[0052] Lubricant 2.0,

[0053] Antioxidant 0.3, ...

Embodiment 2

[0062] This embodiment relates to a magnetic spray-free aesthetic resin composition. The preparation method includes the following steps:

[0063] (1) Prepare materials according to the following components and parts by weight:

[0064] Base resin 100,

[0065] Magnetic Metal Pigments 8.0,

[0066] Pearlescent Pigment 8.0,

[0067] Lubricant 2.0,

[0068] Antioxidant 0.3;

[0069] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then the master batches containing magnetic metal pigments are obtained through the steps of extrusion, drawing, cooling and pelletizing.

[0070] (3) Prepare materials according to the following components and parts by weight:

[0071] Base resin 90,

[0072] Lubricant 2.0,

[0073] Antioxidant 0.3...

Embodiment 3

[0082] This embodiment relates to a magnetic spray-free aesthetic resin composition. The preparation method includes the following steps:

[0083] (1) Prepare materials according to the following components and parts by weight:

[0084] Base resin 100,

[0085] Magnetic Metal Pigments 8.0,

[0086] Pearlescent Pigment 8.0,

[0087] Lubricant 2.0,

[0088] Antioxidant 0.3;

[0089] (2) Put the above-mentioned (1) raw materials into a high-speed mixer according to the formula and stir them. After mixing evenly, send them into the twin-screw extruder through the metering device. Under the conveying, shearing and mixing of materials, the materials are melted and compounded, and then the master batches containing magnetic metal pigments are obtained through the steps of extrusion, drawing, cooling and pelletizing.

[0090] (3) Prepare materials according to the following components and parts by weight:

[0091] Base resin 90,

[0092] Lubricant 2.0,

[0093] Antioxidant 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com