Silver spraying-free polypropylene alloy for lower bumper guard plate and preparation method of alloy

A polypropylene and bumper technology, which is applied in the field of polypropylene, can solve problems such as increased costs, and achieve the effects of reducing flow marks, ensuring light reflectivity, and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

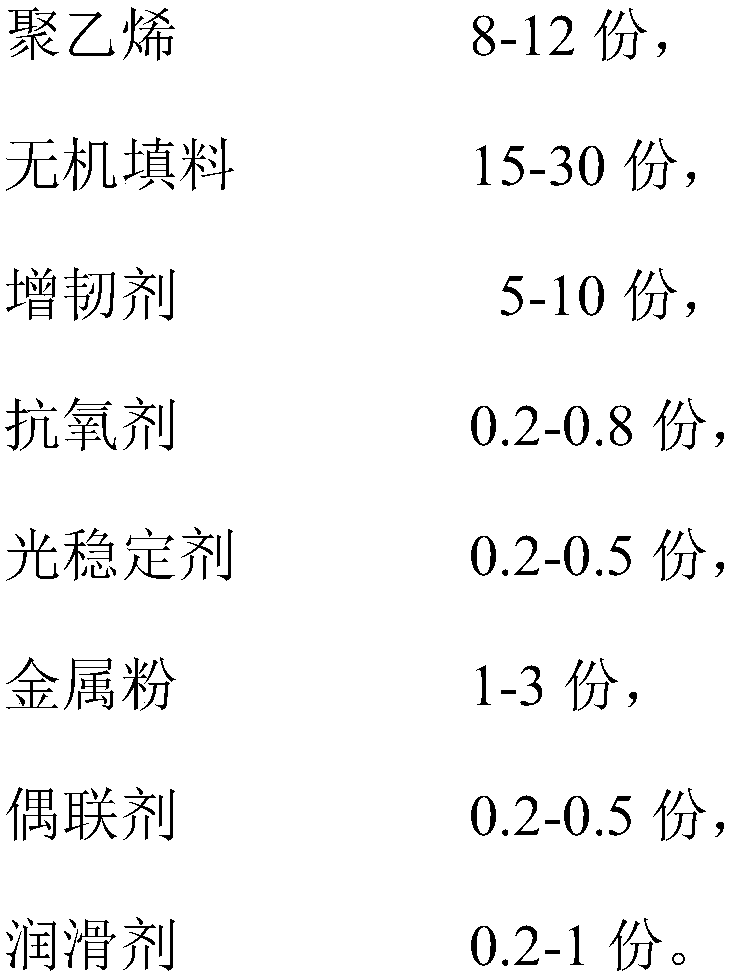

Method used

Image

Examples

Embodiment 1

[0034] 48 parts of copolymerized polypropylene, 12 parts of low density polyethylene, 30 parts of inorganic filler, 10 parts of toughening agent, 0.2 parts of antioxidant 1010, 0.5 parts of silane coupling agent KH550, 0.2 parts of light stabilizer UV-531, 0.2 parts 1 part of lubricant, 1 part of metal powder, add to the high mixer and mix for 5 minutes;

[0035] The mixed blend is extruded and granulated by a twin-screw extruder. The temperature of each zone of the extruder is 150°C, 170°C, 175°C, 175°C, 175°C, 180°C from the feeding section to the head temperature. °C, 180 °C, 180 °C, 180 °C, 185 °C, the length-to-diameter ratio of the extrusion screw is 44, and the rotation speed of the extrusion screw is 350 rpm. The prepared mixture was tested for performance, and the test results are shown in Table 1.

Embodiment 2

[0037] 57 parts of copolymerized polypropylene, 10 parts of low density polyethylene, 25 parts of inorganic fillers, 8 parts of toughening agent, 0.3 parts of antioxidant 168, 0.2 parts of antioxidant 1010, 0.3 parts of antioxidant DSTDP, 0.4 parts of silane Joint agent KH550, 0.3 parts of light stabilizer UV-531, 0.3 parts of lubricant, 1.2 parts of metal powder, add to the high mixer and mix for 10 minutes;

[0038] The mixed blend is extruded and granulated through a twin-screw extruder. The temperature of each zone of the extruder is 170°C, 185°C, 185°C, 185°C, 185°C, 190°C from the feeding section to the head temperature. °C, 195 °C, 195 °C, 195 °C, 200 °C, the length-to-diameter ratio of the extrusion screw is 44, and the rotation speed of the extrusion screw is 350 rpm. The prepared mixture was tested for performance, and the test results are shown in Table 1.

Embodiment 3

[0040] 62 parts of copolymerized polypropylene, 10 parts of low density polyethylene, 20 parts of inorganic fillers, 8 parts of toughening agent, 0.2 parts of antioxidant 168, 0.3 parts of antioxidant 1010, 0.3 parts of silane coupling agent KH550, 0.2 parts of light Stabilizer UV-531, 0.2 parts of light stabilizer TH-944, 0.4 parts of lubricant, 1.5 parts of metal powder, add to the high mixer and mix for 15 minutes;

[0041]The mixed blend is extruded and granulated by a twin-screw extruder. The temperature of each zone of the extruder is 150°C, 170°C, 175°C, 175°C, 175°C, 180°C from the feeding section to the head temperature. °C, 180 °C, 180 °C, 180 °C, 195 °C, the length-to-diameter ratio of the extrusion screw is 48, and the rotation speed of the extrusion screw is 350 rpm. The prepared mixture was tested for performance, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com