Preparation of functional composite material polyvinylhalogenides resin

A vinyl halide and manufacturing method technology, applied in the field of polyvinyl halide resin, can solve problems such as difficult processing and limited application range, and achieve the effects of low flow marks, high melt strength, and low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

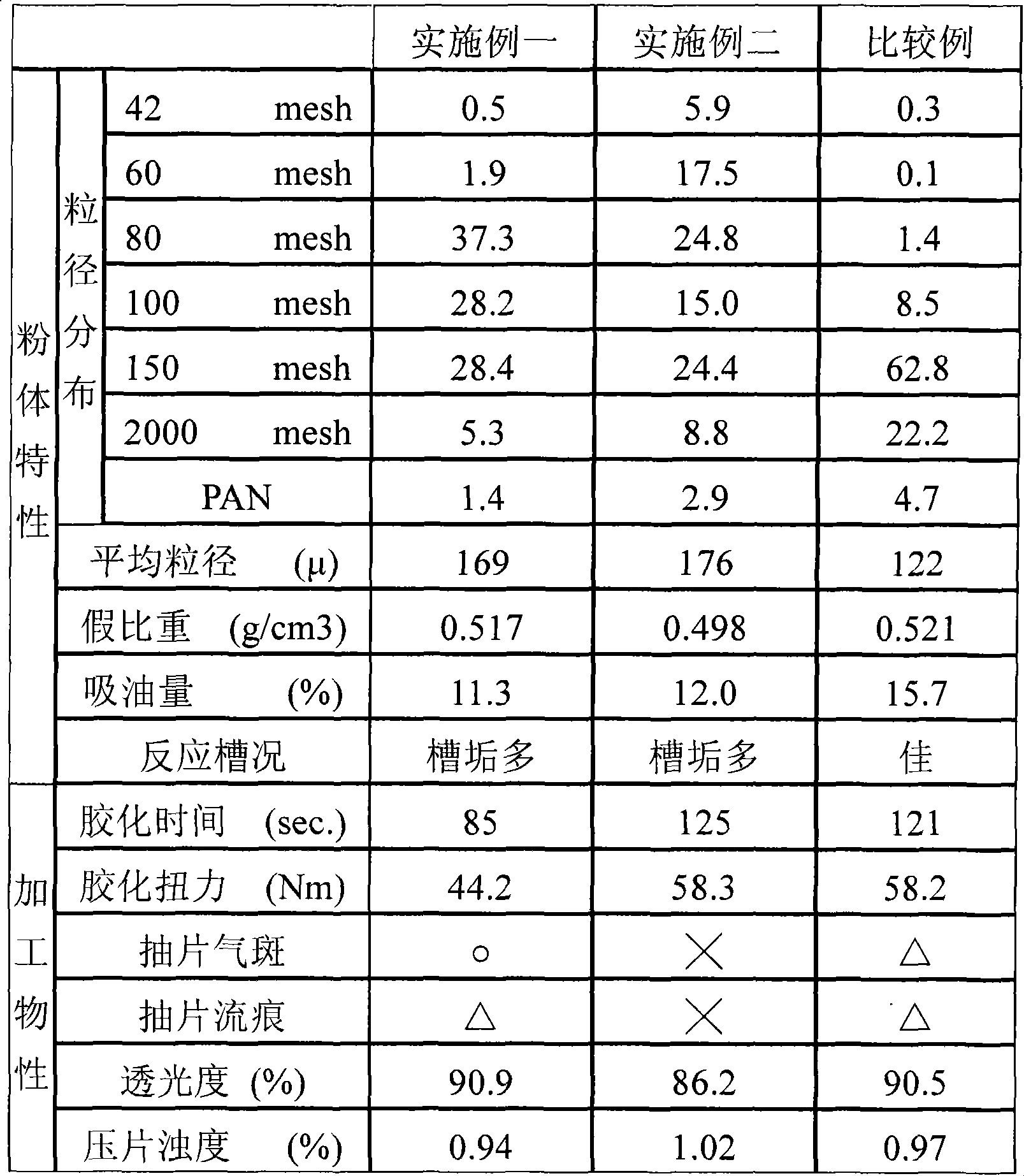

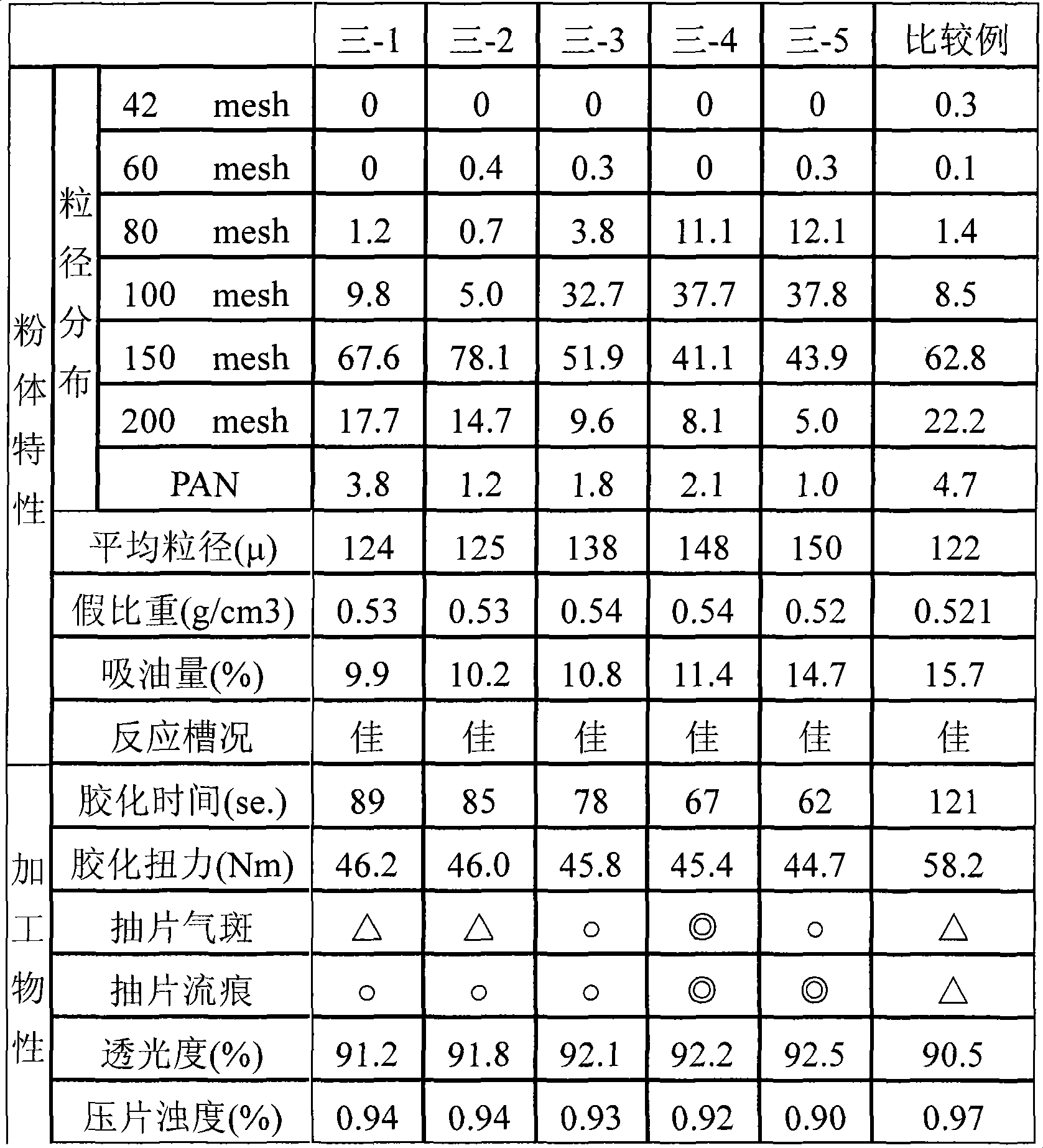

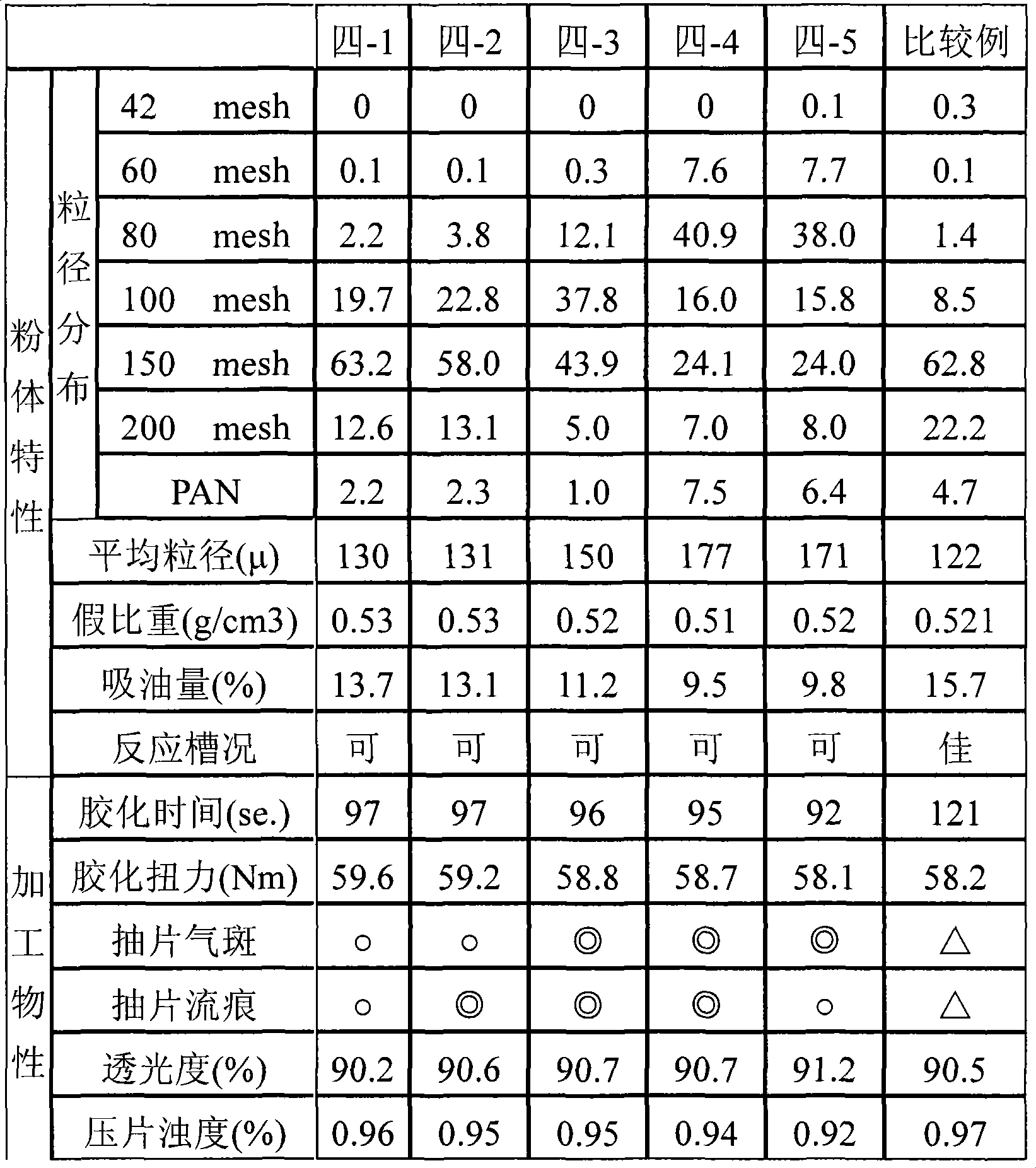

Embodiment 1

[0030] In the 200-liter polymerization tank, add 70 kg of deionized water, add 56 grams of polyvinyl alcohol dispersant (hydrolysis degree 78mol%), lock the tank cover, vacuumize to -740mmHg, keep for 10 minutes, add 70 kg of chlorine Ethylene monomer and peroxide catalyst BND0.56g, heat up to 64°C for reaction, after 90 minutes of reaction, add methyl methacrylate (MMA) and butyl acrylate (BA) monomers continuously The injection time of the mixed liquid is 30 minutes, and the polymerization reaction is continued for 3 hours after the completion of the reaction, and the sample powder is taken after the reaction is completed. Wherein the ratio of the mixed solution added continuously is 140 grams of MMA and 28 grams of BA.

Embodiment 2

[0032] In the 200-liter polymerization tank, add 70 kg of deionized water, 56 grams of polyvinyl alcohol dispersant (degree of hydrolysis 78 mol%), 140 grams of MMA monomer, 28 grams of BA monomer, then lock the tank cover and vacuumize To -740mmHg, keep it for 10 minutes, add 70kg of vinyl chloride monomer and 0.56g of peroxide catalyst BND, raise the temperature to 64°C to carry out polymerization reaction until 5 hours after the reaction is over, take sample powder.

[0033] After the polyvinyl chloride resin polymerization is completed, the sample powder is taken and the dried powder is subjected to the following physical tests:

[0034] 1. Roll test:

Embodiment

[0035] Example formula: 100 parts of PVC (K=60), 1.1 parts of organotin stabilizer, 0.6 parts of slip agent, operating temperature of 190° C., time of 3 minutes, thickness of pumping sheet 0.3 mm.

[0036] Comparative example formula: 100 parts of PVC (K=60), 1.1 parts of organotin stabilizer, 1.2 parts of processing aid, 0.6 parts of slip agent, operating temperature of 190° C., time of 3 minutes, thickness of pumping sheet 0.3 mm.

[0037] 2. Gelation test:

[0038] Example formula: 100 parts of PVC (K=60), 1.1 parts of organotin stabilizer, 0.6 parts of lubricant, plastic spectrometer HAAKE BUCHLER SYSTEM 40, temperature setting 140°C, rotation speed 45rpm.

[0039] Comparative example formula: 100 parts of PVC (K=60), 1.1 parts of organotin stabilizer, 1.2 parts of processing aid, 0.6 parts of slip agent, plastic spectrometer HAAKE BUCHLER SYSTEM 40, temperature setting 140°C, rotation speed 45rpm.

[0040] 3. Air spot and flow mark test on the slice:

[0041] Example fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com