Spraying-free PP/PCTG alloy material with colorful effect and preparation method thereof

An alloy material, spray-free technology, applied in the field of PP alloy materials, can solve the problems of flow marks on the surface of the workpiece, easy to be squeezed, ground, insufficient flashing effect, etc., to achieve excellent low temperature resistance and surface gloss, Improve the mechanical properties, the effect of good magic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] The present invention provides the preparation method of the spray-free PP / PCTG alloy material with illusion effect described in the above scheme, comprising the following steps:

[0052] Weigh each component according to the formula, and mix other components except the magic pearlescent masterbatch to obtain a mixture; the magic pearlescent masterbatch is fed by side feeding and extruded together with the mixture Granules, to obtain a spray-free PP / PCTG alloy material with a magic effect.

[0053] The invention mixes other components except the magic pearl masterbatch to obtain the mixture. Before the mixing, in the present invention, the PCTG is preferably dried at 80-90°C. In the present invention, the mixing is preferably performed in high-speed mixing equipment, and the rotation speed of the high-speed mixing equipment is preferably 500-700 r / min, more preferably 600 r / min.

[0054] After the mixed material is obtained, the present invention feeds the magic color...

Embodiment 1

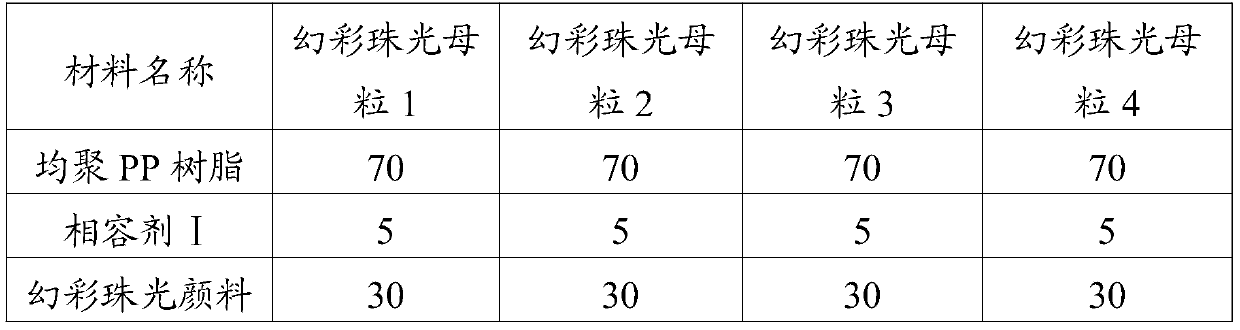

[0058] Prepare the magic color pearl masterbatch according to the materials and components in Table 1.

[0059] The preparation method is: mix homopolymer PP resin, compatibilizer Ⅰ, magic pearlescent pigment, antioxidant and lubricant with a low-speed mixer for one minute, then add coupling agent and alignment agent by spraying, and pour the mixture into Put it into a continuous internal mixer for extrusion granulation, the temperature of the internal mixing room is 180-190°C, the internal mixing speed is 180rpm, the feeding speed is 12rpm, the temperature of the internal mixer is 180-205°C, and the main engine speed is 200rpm, to obtain Symphony Pearlescent Masterbatch 1-4.

[0060] In Table 1, the homopolymerized PP resin is high-flow transparent grade PP particles, and the melt index flow rate is 28g / 10min; the compatibilizer I is maleic anhydride grafted polypropylene, the graft ratio is 1.2%, and the melt index is 100g / 10min; the iridescent pearlescent pigment is a thr...

Embodiment 2

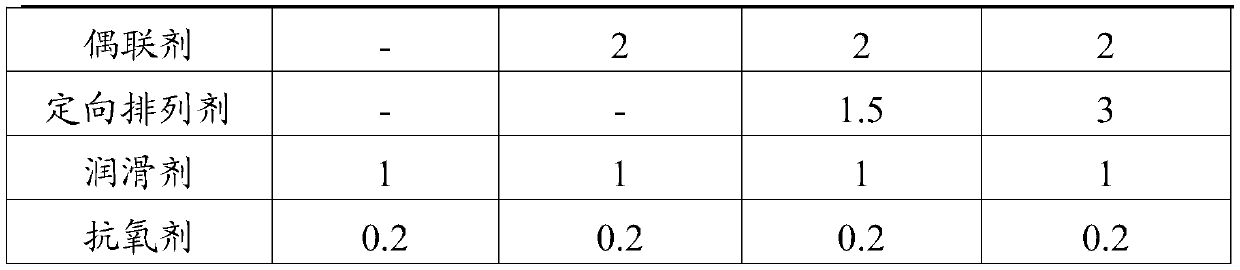

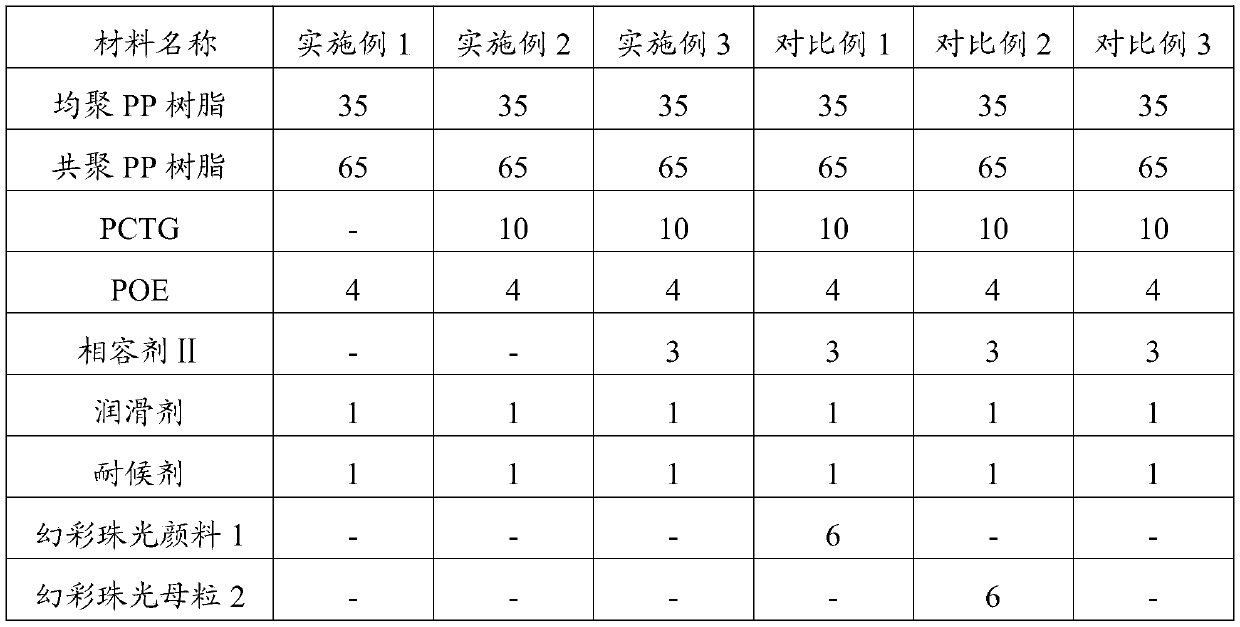

[0065] Prepare the spray-free PP / PCTG alloy material with illusion effect according to the materials and components in Table 2.

[0066] The preparation method is as follows: homopolymer PP resin, copolymer PP resin, PCTG, POE, compatibilizer II, lubricant and weather resistance agent are fully mixed in a high mixing pot for 6-10 minutes, and the mixture is fed into the extruder. Mouth extrusion granulation, magic color pearlescent masterbatch is fed by side feeding, which can effectively reduce the shearing of the screw. The temperature of the extruder is 180-220°C, the rotation speed of the main engine is 200rpm, and the feeding speed is 12rpm; the side feeding is 5-10rpm, and the temperature of the side feeding equipment is 180-205°C; after melt extrusion and granulation, the product with Spray-free PP / PCTG alloy material with illusion effect.

[0067] In Table 2, the copolymerized PP resin is a high-flow random copolymerized particle, and the melt finger flow rate is 22g / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com