Low-flow-mark low-weld-mark polypropylene composition and preparation method thereof

A polypropylene composition and welding line technology, applied in the field of polypropylene composition, can solve the problems of bimodal polypropylene welding lines, low melt flow rate of polypropylene composition, poor processing performance, etc., and achieve low welding line, The effect of improving melt flow and reducing flow differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

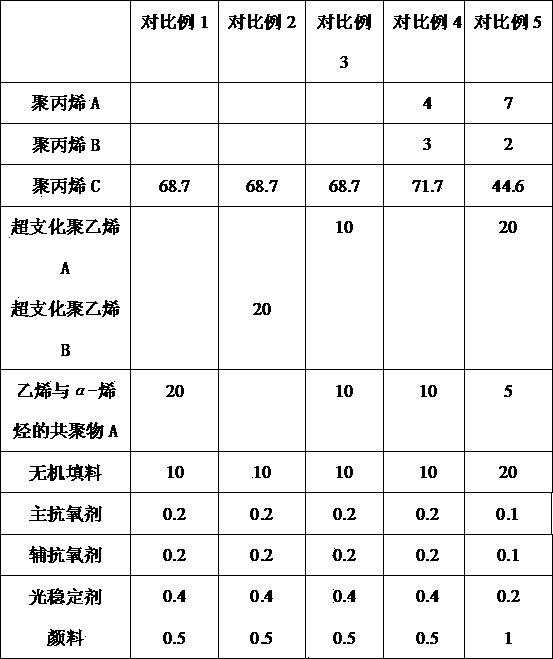

Examples

Embodiment 1

[0041] Take by weighing 1.5wt% polypropylene A, 8.5wt% polypropylene B, 48.7wt% polypropylene C, 10wt% hyperbranched polyethylene A, 20wt% ethylene and α - Olefin copolymer A, 10% talc, 0.2wt% primary antioxidant DSTP, 0.2wt% secondary antioxidant 168, 0.2wt% light stabilizer 770, 0.2wt% light stabilizer 944 and 0.5 wt% of the pigment was mixed in a high-speed mixer for 3 minutes at a speed of 1000 rpm, and then the mixture was added to a twin-screw extruder for melting and mixing, and extruded to granulate. The process is: 190°C in the first zone, 210°C in the second zone, 220°C in the third zone, and 205°C in the fourth zone; the residence time of the entire extrusion process is 1 minute, and the pressure is 15MPa.

Embodiment 2

[0043] Take by weighing 4wt% polypropylene A, 3wt% polypropylene B, 61.7wt% polypropylene C, 10wt% hyperbranched polyethylene A, 10wt% ethylene and α - Olefin copolymer A, 10 wt% inorganic filler, 0.2 wt% primary antioxidant DSTP, 0.2 wt% secondary antioxidant 168, 0.4 wt% light stabilizer 770 and 0.5 wt% pigments were put into high speed Blending in the mixer for 4 minutes, the rotation speed is 1000 rpm, and then the mixture is added to a twin-screw extruder for melting and kneading, and extruded to granulate. The process is as follows: the first zone is 200°C, the second zone is 200°C, the third zone is 210°C, and the fourth zone is 215°C; the residence time of the entire extrusion process is 2 minutes, and the pressure is 19MPa.

Embodiment 3

[0045] Take by weighing 3wt% polypropylene A, 6wt% polypropylene B, 44.6wt% polypropylene C, 20wt% hyperbranched polyethylene A, 5wt% ethylene and α - Olefin copolymer A, 20wt% inorganic filler, 0.1wt% primary antioxidant 1010, 0.1wt% secondary antioxidant 618, 0.1wt% light stabilizer 770, 0.1wt% light stabilizer 944 and 1wt% of the pigment was mixed in a high-speed mixer for 5 minutes at a speed of 1000 rpm, then the mixture was added to a twin-screw extruder for melting and mixing, and extruded to granulate. The process is as follows: the first zone is 200°C, the second zone is 205°C, the third zone is 215°C, and the fourth zone is 210°C; the residence time of the entire extrusion process is 2 minutes, and the pressure is 13MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com